A high-sensitivity phosphor material for temperature sensing and its preparation method

A high-sensitivity, phosphor technology, used in luminescent materials, chemical instruments and methods, etc., can solve the problems of unstable physical and chemical properties of fluoride, sensitive to oxygen surface contact, strong corrosiveness and volatility, etc., and achieve low production costs. , Simple operation, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

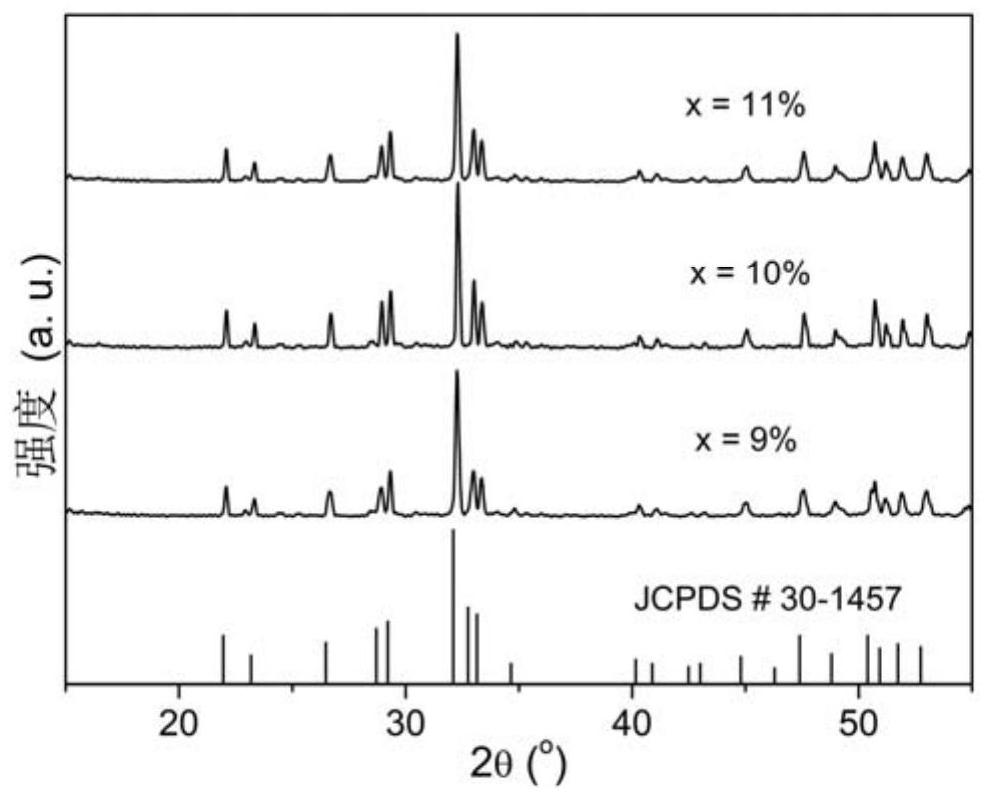

Embodiment 1

[0030] Step 1: Accurately weigh the initial raw material Y 2 o 3 , SiO 2 , Yb 2 o 3 and Ho 2 o 3 , and the cosolvent Li 2 CO 3 In an agate mortar, grind after adding sewage ethanol, and mix evenly; the purity of the initial raw material and co-solvent are both 99.99%; Y 2 o 3 , SiO 2 , Yb 2 o 3 ,Ho 2 o 3 with Li 2 CO 3 The mass ratio of Y is 264:100:45.9:4.4:8.29; Y 2 o3 , SiO 2 , Yb 2 o 3 ,Ho 2 o 3 and Li 2 CO 3 The mass and the ratio of ethanol to ethanol are 1g / (4~7ml);

[0031] Step 2, put the ground mixture in a 5ml corundum crucible, and burn it in a heating furnace. After the burning is completed, take out the crucible after the heating furnace cools down, and grind it to obtain a powdery product, that is, the molecular formula of the obtained phosphor material is Y 4.20767 Yb 0.4203 Ho 0.04203 Si 3 o 13 , that is, the molecular formula of the phosphor material Y 4.67(1-x-y) Yb 4.67x Ho 4.67y Si 3 o 13 Take x=9% and y=0.9%; the heating f...

Embodiment 2

[0033] Step 1: Accurately weigh the initial raw material Y 2 o 3 , SiO 2 , Yb 2 o 3 and Ho 2 o 3 , and the cosolvent Li 2 CO 3 In an agate mortar, grind after adding sewage ethanol, and mix evenly; the purity of the initial raw material and co-solvent are both 99.99%; Y 2 o 3 , SiO 2 , Yb 2 o 3 ,Ho 2 o 3 with Li 2 CO 3 The mass ratio of Y is 257:100:56.2:5.9:8.38; Y 2 o 3 , SiO 2 , Yb 2 o 3 ,Ho 2 o 3 and Li 2 CO 3 The mass and the ratio of ethanol to ethanol are 1g / (4~7ml);

[0034] Step 2, put the ground mixture in a 5ml corundum crucible, and burn it in a heating furnace. After the burning is completed, take out the crucible after the heating furnace cools down, and grind it to obtain a powdery product, that is, the molecular formula of the obtained phosphor material is Y 4.10026 Yb 0.5137 Ho 0.05604 Si 3 o 13 , that is, the molecular formula of the phosphor material Y 4.67(1-x-y) Yb 4.67x Ho 4.67y Si 3 o 13 Take x=11% and y=1.2%; the heatin...

Embodiment 3

[0036] Step 1: Accurately weigh the initial raw material Y 2 o 3 , SiO 2 , Yb 2 o 3 and Ho 2 o 3 , and the cosolvent Li 2 CO 3 In an agate mortar, grind after adding sewage ethanol, and mix evenly; the purity of the initial raw material and co-solvent are both 99.99%; Y 2 o 3 , SiO 2 , Yb 2 o 3 ,Ho 2 o 3 with Li 2 CO 3 The mass ratio of Y is 260:100:51.1:4.9:8.32; Y 2 o 3 , SiO 2 , Yb 2 o 3 ,Ho 2 o 3 and Li 2 CO 3 The mass and the ratio of ethanol to ethanol are 1g / (4~7ml);

[0037] Step 2, put the ground mixture in a 5ml corundum crucible, and burn it in a heating furnace. After the burning is completed, take out the crucible after the heating furnace cools down, and grind it to obtain a powdery product, that is, the molecular formula of the obtained phosphor material is Y 4.1563 Yb 0.467 Ho 0.0467 Si 3 o 13 , that is, the molecular formula of the phosphor material Y 4.67(1-x-y) Yb 4.67x Ho 4.67y Si 3 o 13 Take x=10% and y=1%; the heating fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com