Method for manufacturing unidirectional special wear-resistant heavy load-resistant hardened gear

A production method, one-way technology, applied in the direction of quenching agent, quenching device, manufacturing tools, etc., to achieve the effect of not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0061] When the present invention is used, the following steps are included:

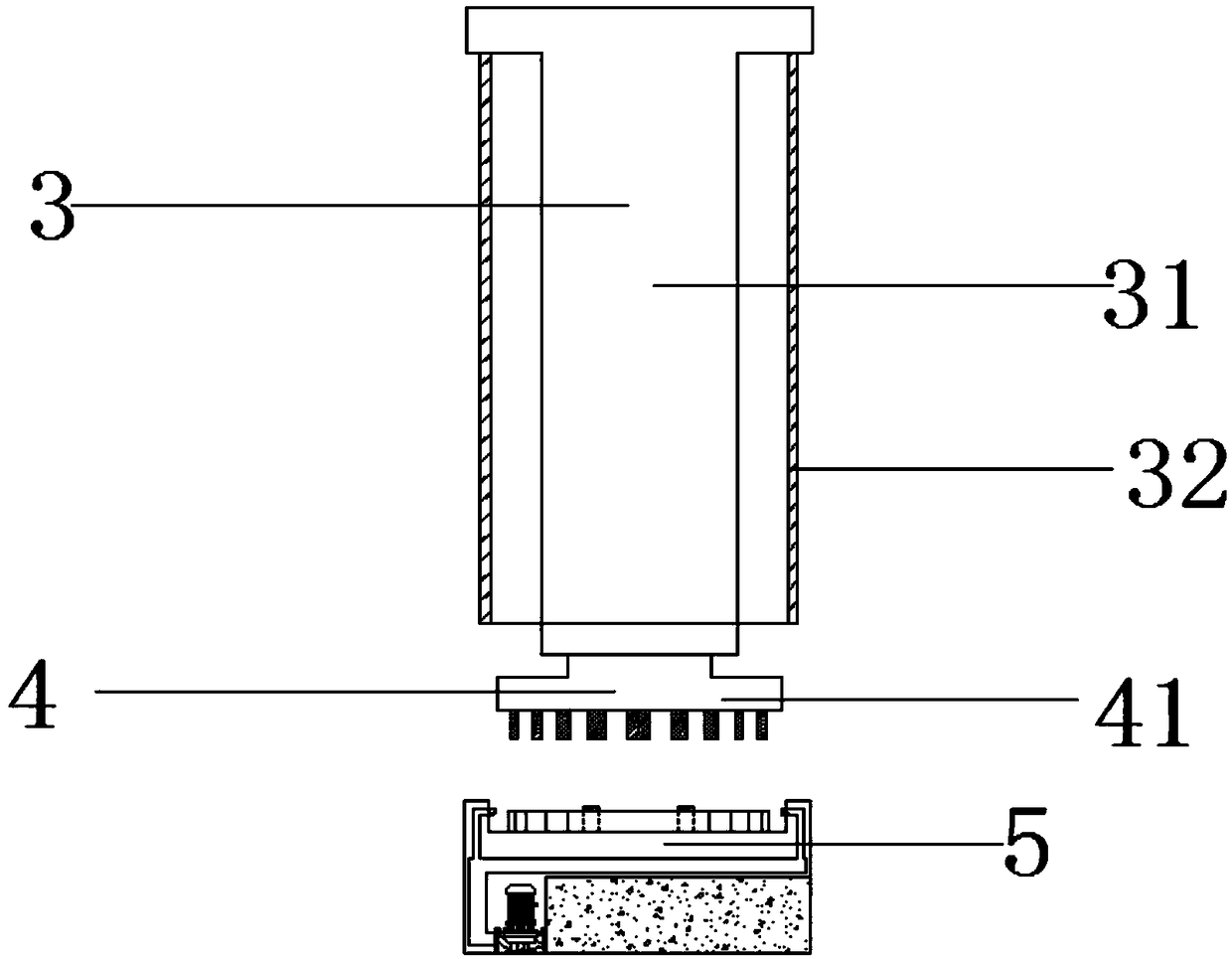

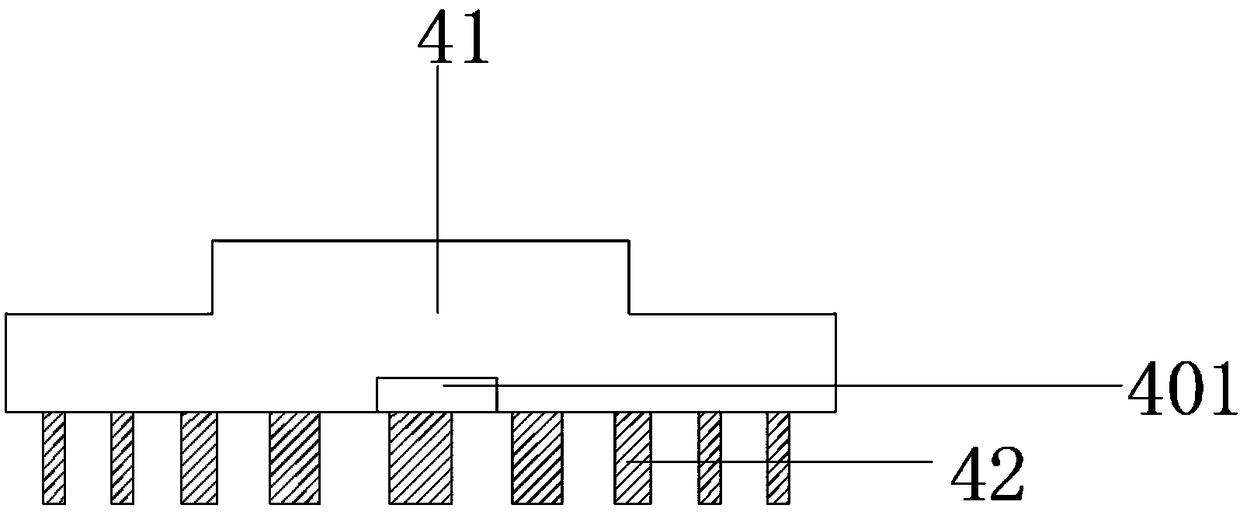

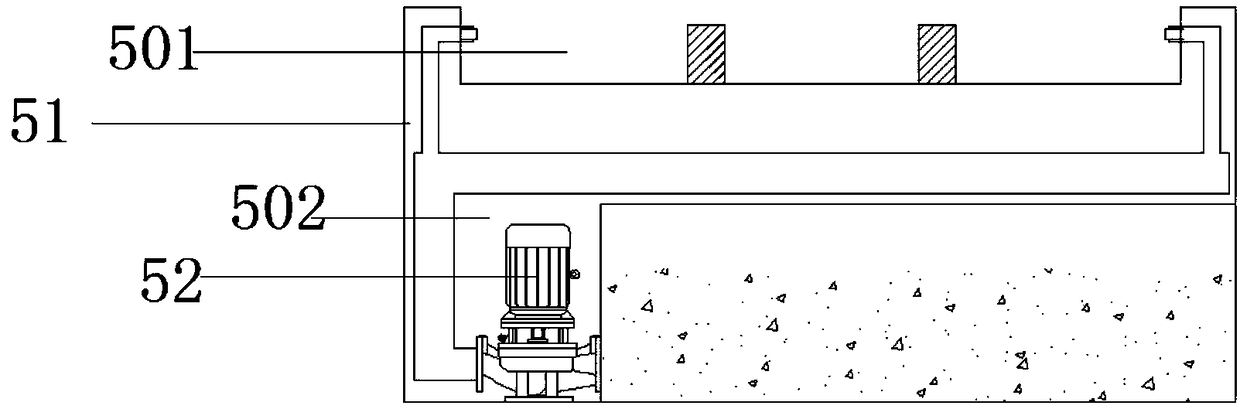

[0062] Using the present invention, the user places the gear body in the fixed groove, and connects the keyway of the gear with the clamping column, thereby fixing the direction of the gear. At this time, the user starts the present invention, and the movable rod of the cylinder drives the quenching device to descend, and the quenching device is lowered in the position of the guide sleeve of the cylinder. Vertically downward under constraints, when the quenching device is close to the fixed cooling device below, the infrared distance sensor sends a signal to the control device, the control system turns on the quenching heating switch, and starts to heat the heating plate, and the position of the heating plate is close to the teeth of the gear body after falling On the large load surface of the gear teeth, start to quench the gear teeth. Due to the effect of the heat shield, the other side of the gear...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap