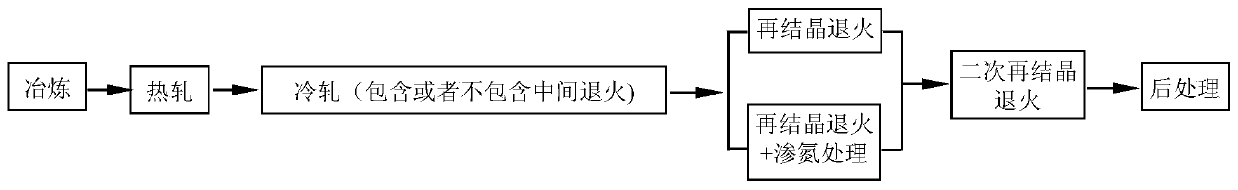

A kind of preparation method of oriented high-silicon steel strip and its high-efficiency annealing mode

A high-silicon steel and annealing technology, applied in the metallurgical field, can solve the problems of sensitive magnetic property nitriding process, complicated equipment maintenance, and inability to dynamically monitor product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] An oriented high-silicon steel thin strip, the composition of the thin strip is shown in Table 1 by weight percentage, and the balance is Fe and other unavoidable impurities.

[0074] A method for preparing a high-efficiency annealing mode of an oriented high-silicon steel strip, comprising the steps of:

[0075] step 1:

[0076] Smelt according to the set composition of 9 groups of oriented high-silicon steel thin strips in Table 1, and die-cast into slabs at 1440-1600 °C;

[0077] Step 2:

[0078] Heating the slab to 1250°C for a holding time of 90 minutes; then performing hot rolling with a starting temperature of 1150°C and a final rolling temperature of 950°C to obtain a hot-rolled sheet with a thickness of 2.2mm;

[0079] Step 3:

[0080] Pickling the hot-rolled plate to remove the oxide layer;

[0081] Step 4:

[0082] The hot-rolled plate after pickling is rolled by the second cold rolling method, the first rolling reduction rate is 70%, the rolling tempera...

Embodiment 2

[0094] An oriented high-silicon steel thin strip, the thin strip composition by weight percentage is: Si: 4.5%, C: 0.05%, Als: 0.03%, N: 0.006%, Mn: 0.08%, Cu: 0.5%, S : 0.007%, Nb: 0.15%, V: 0.005%, Sn: 0.06%, Mo: 0.05%, Cr: 0.1%, and the balance is Fe and other unavoidable impurities.

[0095] A method for preparing a high-efficiency annealing mode of an oriented high-silicon steel strip, comprising the steps of:

[0096] step 1:

[0097] Smelted according to the set composition of oriented high-silicon steel thin strip, molded into slab at 1500℃;

[0098] Step 2:

[0099] Heating the slab to 1280°C for a holding time of 30 minutes; then performing hot rolling at a starting temperature of 1200°C and a final rolling temperature of 1050°C to obtain a hot-rolled sheet with a thickness of 3 mm;

[0100] Step 3:

[0101] The hot-rolled sheet is subjected to normalization treatment, the temperature during the normalization treatment is 800°C, the time is 600min, and then water...

Embodiment 3

[0112] An oriented high-silicon steel thin strip, the composition of the thin strip by weight percentage is: Si: 7.0%, C: 0.1%, Als: 0.05%, N: 0.003%, Mn: 0.1%, Cu: 0.5%, S : 0.035%, Nb: 0.4%, V: 0.1%, Mo: 1.0%, Cr: 1.0%, B: 0.5%, and the balance is Fe and other unavoidable impurities.

[0113] A method for preparing a high-efficiency annealing mode of an oriented high-silicon steel strip, comprising the steps of:

[0114] step 1:

[0115] Smelted according to the set composition of oriented high-silicon steel thin strip, and molded into slabs at 1440°C;

[0116] Step 2:

[0117] Heating the slab to 1200°C for a holding time of 120 minutes; then performing hot rolling at a starting temperature of 1120°C and a final rolling temperature of 900°C to obtain a hot-rolled sheet with a thickness of 1.5mm;

[0118] Step 3:

[0119] The hot-rolled sheet is subjected to normalization treatment, the temperature during the normalization treatment is 1200°C, the time is 1min, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com