Flexible hexagonal ferrite thin film and preparation method thereof

A technology of hexagonal ferrite and thin film, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems that the preparation method has not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

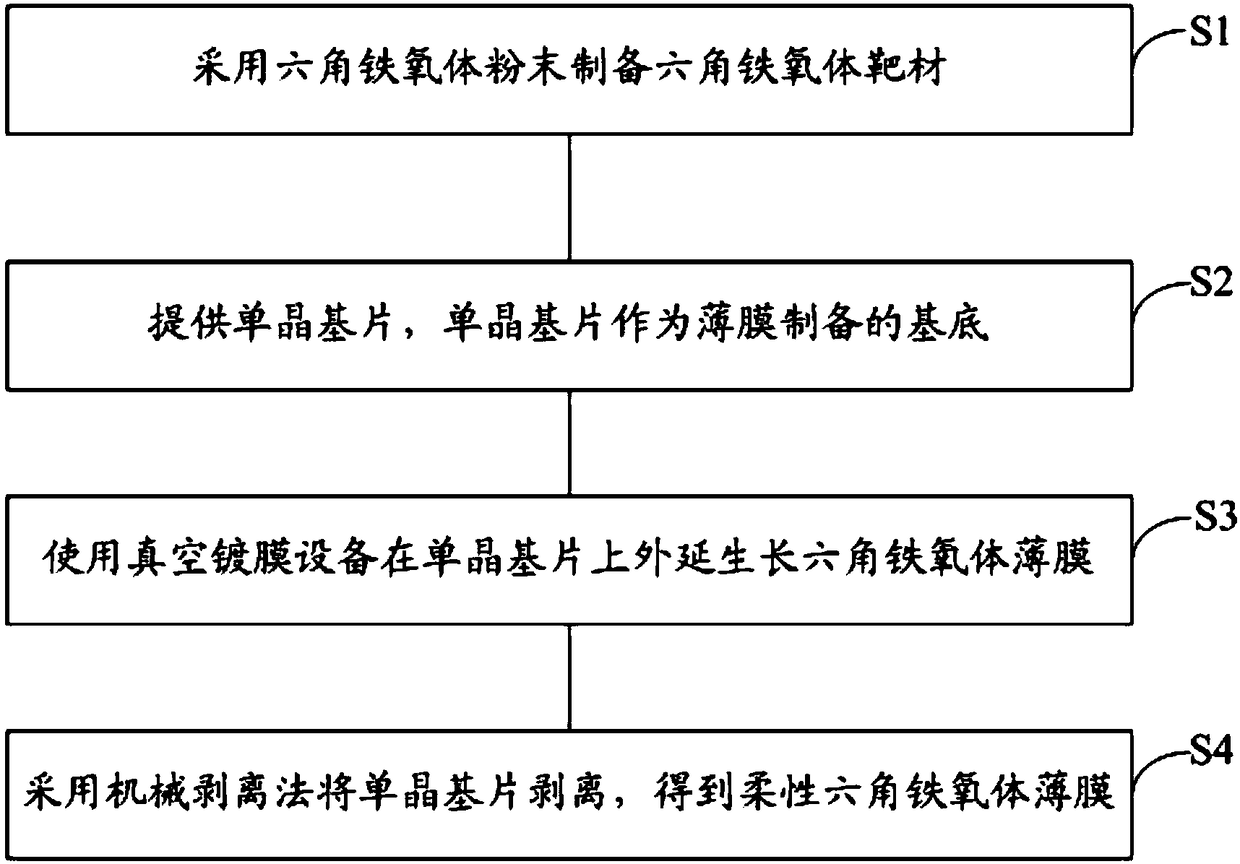

[0041] ginseng figure 1 As shown, the invention discloses a preparation method of a flexible hexagonal ferrite film, which specifically includes:

[0042] S1. Prepare a hexagonal ferrite target by using hexagonal ferrite powder. Among them, the hexagonal ferrite powder includes BaCO 3 Powder and / or SrCO 3 powder, and Fe 2 o 3 powder.

[0043] Step S1 is specifically:

[0044] S11, BaCO with a purity higher than 99.95% 3 Powder and / or SrCO 3 powder, and Fe 2 o 3 The powders are weighed in proportion, mixed uniformly, ground, and then the hexagonal ferrite powder is annealed (the annealing temperature is 550°C-1100°C, the annealing time is 5-20h), and cooled naturally. Preferably, BaCO is selected as the hexagonal ferrite powder 3 and Fe 2 o 3 When BaCO 3 and Fe 2 o 3 The molar ratio is 1:5.5 to 1:6.5; when choosing SrCO 3 and Fe 2 o 3 When SrCO 3 and Fe 2 o 3 The molar ratio is 1:5.5 to 1:6.5; when BaCO is selected 3 , SrCO 3 and Fe 2 o 3 When BaCO 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com