Ultra-light Hanging Basket Main Truss

An ultra-light, basket-based technology, which is applied in the erection/assembly of bridges, buildings, bridge construction, etc., can solve the problems of complex structure, high safety risk, and high center of gravity of the hanging basket, so as to simplify the construction process, reduce the work coefficient, and reduce the front end The effect of displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

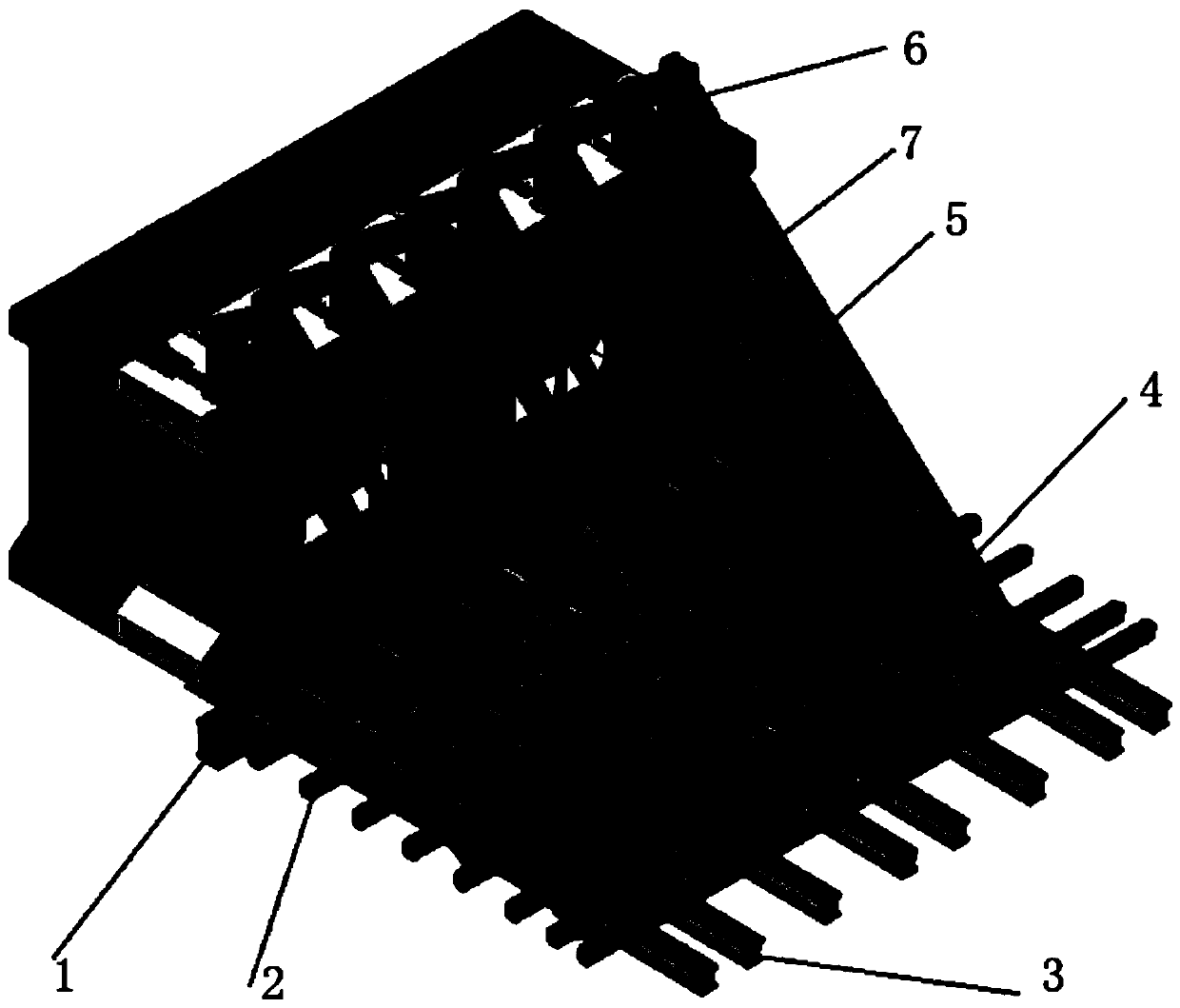

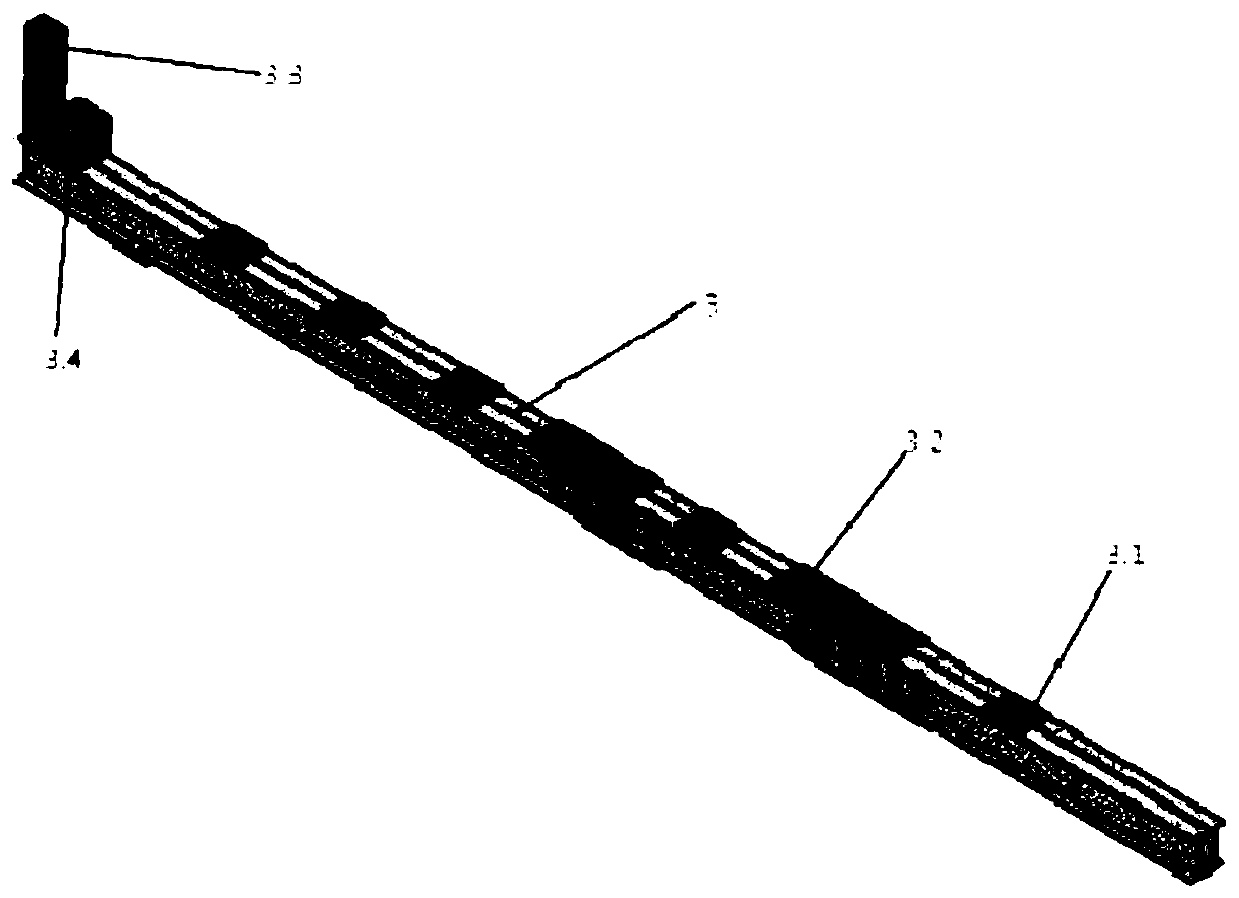

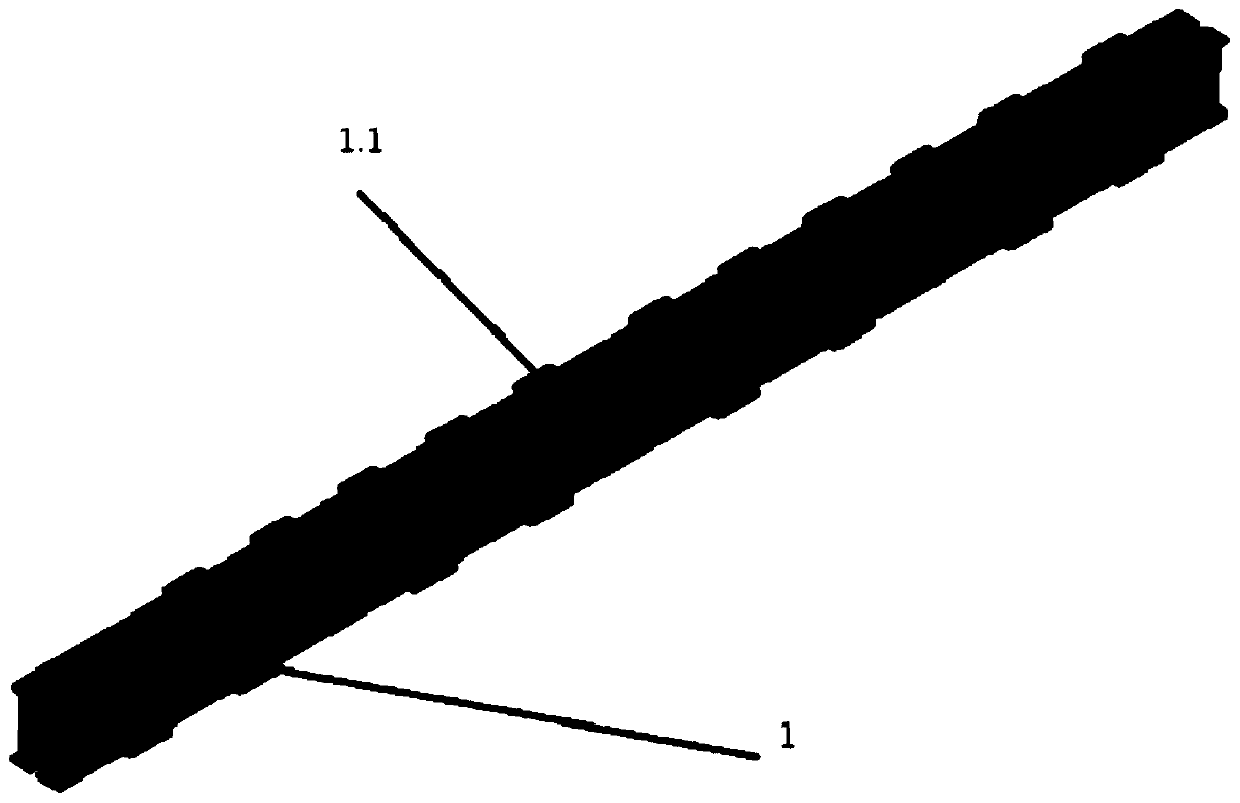

[0029] Ultra-light hanging basket main truss, such as Figure 1-6 As shown, it includes main beam 1, secondary beam 2, longitudinal beam 3, steel sling system, embedded structure 6 and anchor screw 7. The number of the main beam 1 is one, the number of the secondary beams 2 is eight, and they are arranged on the longitudinal beams 3 at equal intervals, and the number of the longitudinal beams 3 is eight, and they are arranged at equal intervals. The invention has the advantages of small displacement of the front end of the hanging basket at the rear fulcrum, which reduces the control difficulty of hanging construction; the main truss of the hanging basket is lowered. The center of gravity of the hanging basket is low, and the walking and working stability...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com