A Drill Bit with Adjustable Crosshair Initial Phase Combination for Deep Stirring Pile Driver

A technology of deep mixing piles and initial phases, applied in the direction of drill bit, sheet pile wall, earthwork drilling and mining, etc., can solve problems such as blade collision, achieve the effect of ensuring smooth progress and solving collision problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The present invention is used in a pouring construction project where the mixing depth of the deep-layer mixing pile driver is 10m, and the specific assembly conditions and requirements are as follows:

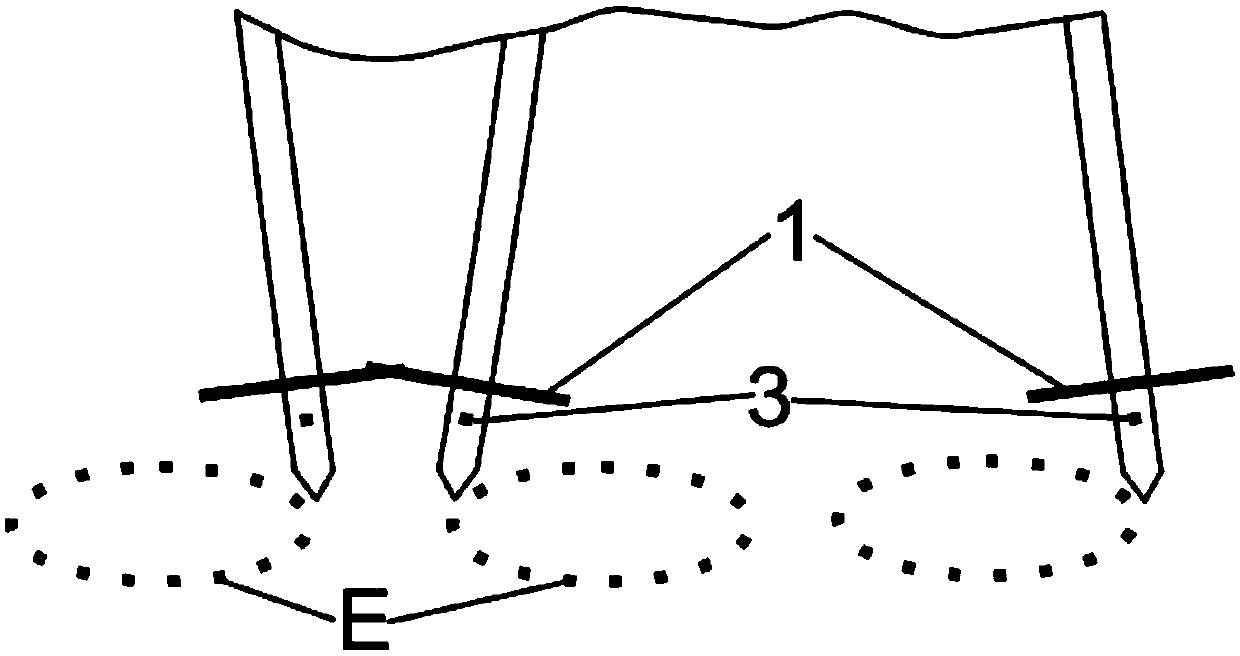

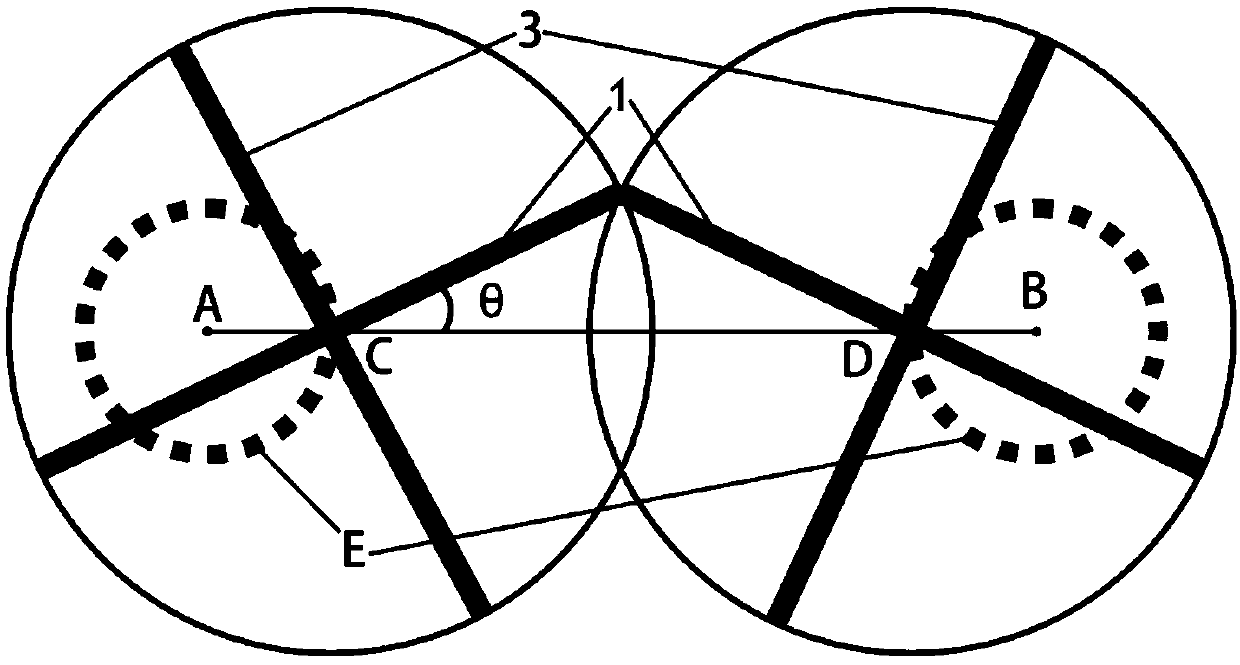

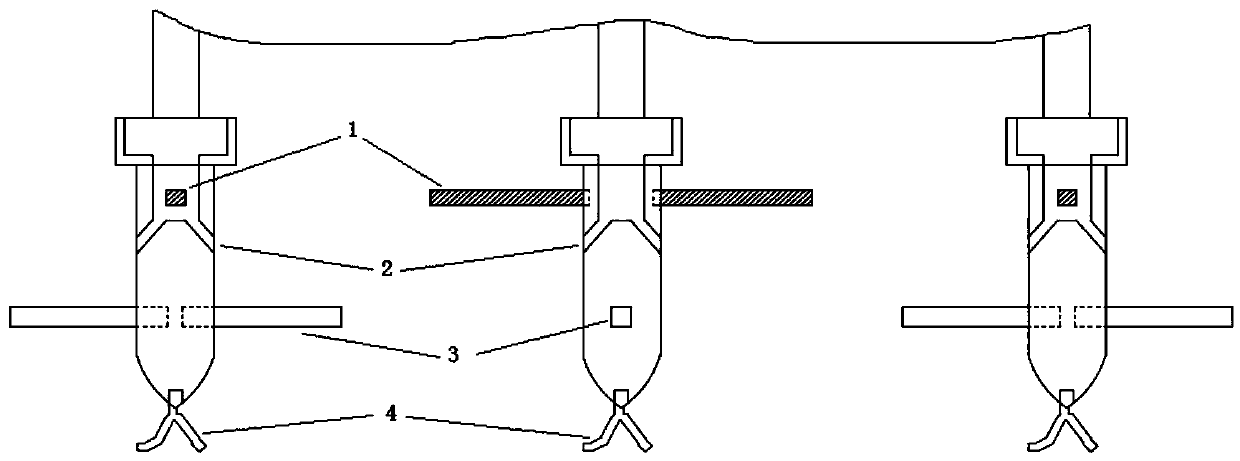

[0018] The present invention proposes an adjustable reticle initial phase combination drill bit for deep-layer mixing pile drivers. Before assembly, the initial phase between blades of the same layer of adjacent drill bits is determined according to the mixing depth, and is obtained according to the general situation of a pouring construction project. The elastic modulus E of the drill pipe is 206850000kN / m 2 , the moment of inertia of the drill pipe is 0.00003586m 4 , the density of the mixed cement mortar is 1900kg / m 3 , The cohesive force of cement mortar is 0kPa, the internal friction angle of cement mortar is 35°, and the calculated value g of gravity is 10N / kg. When drilling 10m, the calculated turning radius is 62.7mm. According to attached figure 2 What the...

Embodiment 2

[0022] The present invention is used in a pouring construction project with a stirring depth of 11.5m for a deep-layer mixing pile machine. Deep mixing pile driver, its structure object is the same as embodiment 1, and the calculation parameters of a certain pouring construction project whose mixing depth is 11.5m are all the same as the calculation parameters in the engineering situation of embodiment 1 except the mixing depth. When drilling 11.5m, the calculated turning radius is 109.8mm. According to attached figure 2 The dotted line shown in the figure shows the orbit of the axis of the drill bit with a radius of 109.8mm. Taking the adjacent drill bit with a center distance of 450mm as an example, the diameter of the drill bit is 350mm at this time, that is, the length of the same-layer blade is 350mm. attached figure 2 This is a critical state, and the critical angle at this time is 48.8° calculated by the geometric relationship. When the initial phase of the same-la...

Embodiment 3

[0024] The present invention is used in a pouring construction project with a stirring depth of 13.8m for a deep-layer mixing pile machine. Deep mixing pile driver, its structure object is the same as that of embodiment 1, and the calculation parameters of a pouring construction project with a mixing depth of 13.8m are all the same as those of the engineering situation in embodiment 1 except for the mixing depth. When drilling 13.8m, the circle radius obtained by calculation is 227.6mm. According to attached figure 2The dotted line shown in the figure shows that the radius is 227.6mm. Taking the adjacent drill bit with a center distance of 450mm as an example, the diameter of the drill bit is 350mm at this time, that is, the length of the same-layer blade is 350mm. attached figure 2 This is a critical state, and the critical angle at this time is 90° through geometric calculation. When the initial phase of the same-layer blades of adjacent drill bits is equal to 90°, no c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com