Coalbed methane horizontal well hole collapse cave-building pressure relief developing system and method

A technology for horizontal wells and coalbed methane, applied in the direction of mining fluids, earthwork drilling, boreholes/well components, etc., can solve problems such as low permeability, inability to realize efficient development of structural coal coalbed methane, and poor effect of transformation methods, to achieve Highlight the effect of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

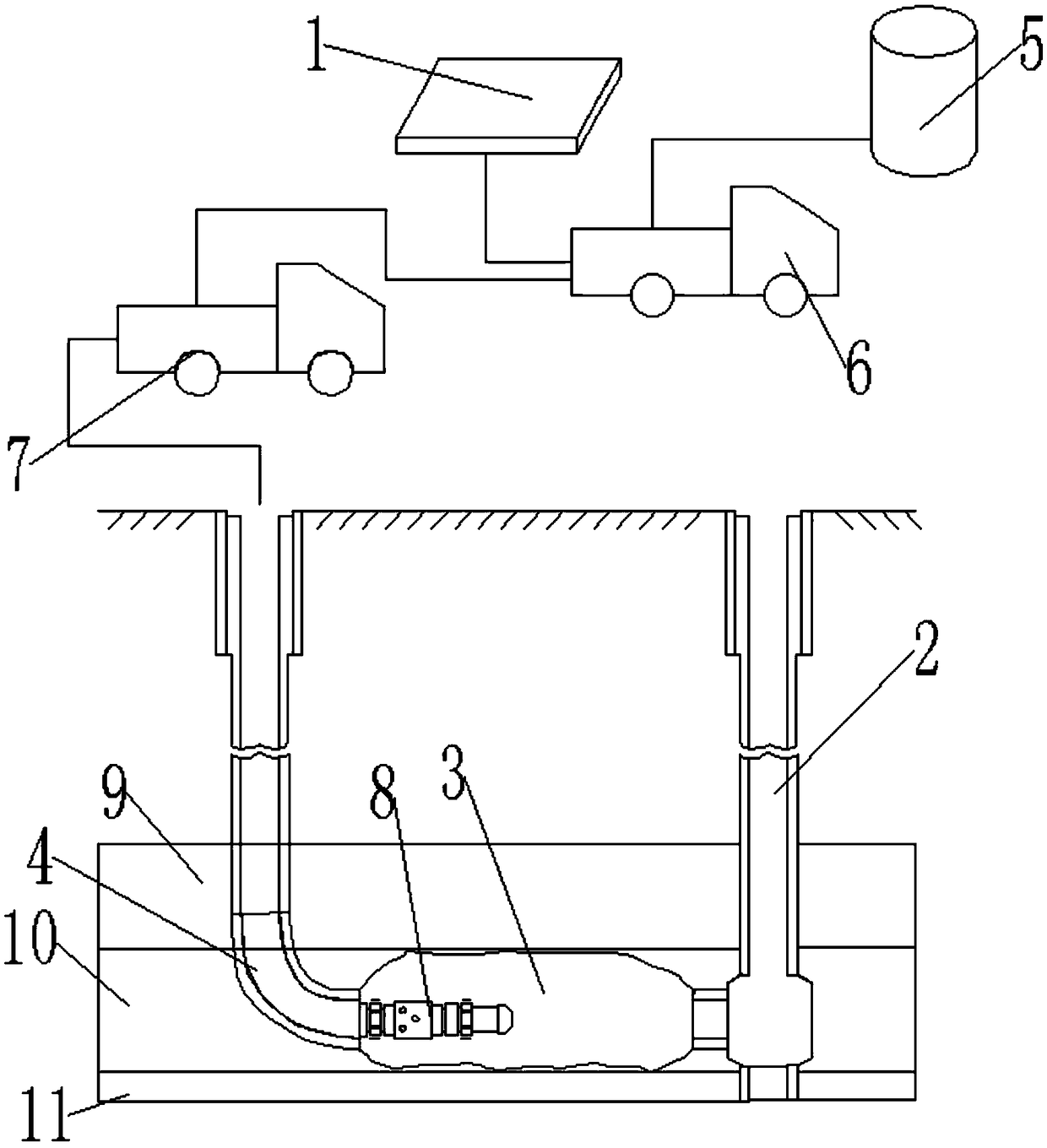

[0020] like figure 1 As shown in the figure, a coalbed methane horizontal well cave-in cave pressure relief development system includes a liquid storage tank 1, an abrasive tank 5, an abrasive mixing device 6, a ground power device 7, and a downhole injection device 8. The entrances of the abrasive mixing device 6 are respectively It communicates with the liquid storage tank 1 and the abrasive tank 5, the outlet communicates with the inlet of the surface power unit 7 (high-pressure pulsation pump), and the outlet of the ground power unit 7 communicates with the downhole injection device 8, which is located in the horizontal section of the horizontal well 4 near the wellhead The injection port faces the vertical well 2; the vertical well 2 and the horizontal well 4 connect to form a U-shaped well, and the horizontal section of the horizontal well 4 is located in the coal sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com