Load-supporting sound insulation cushion

A shock-absorbing pad and load-bearing technology, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of easy failure, poor sound insulation and shock absorption effect, and achieve low cost, large bearing capacity, Good sound insulation and shock absorption effect

Inactive Publication Date: 2018-11-16

廖增强

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The existing sound-proof and shock-absorbing pads with a certain load-bearing capacity are basically directly placed on or under the spring by rubber. This method has the disadvantages of poor sound-proof and shock-absorbing effect and easy failure.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 2

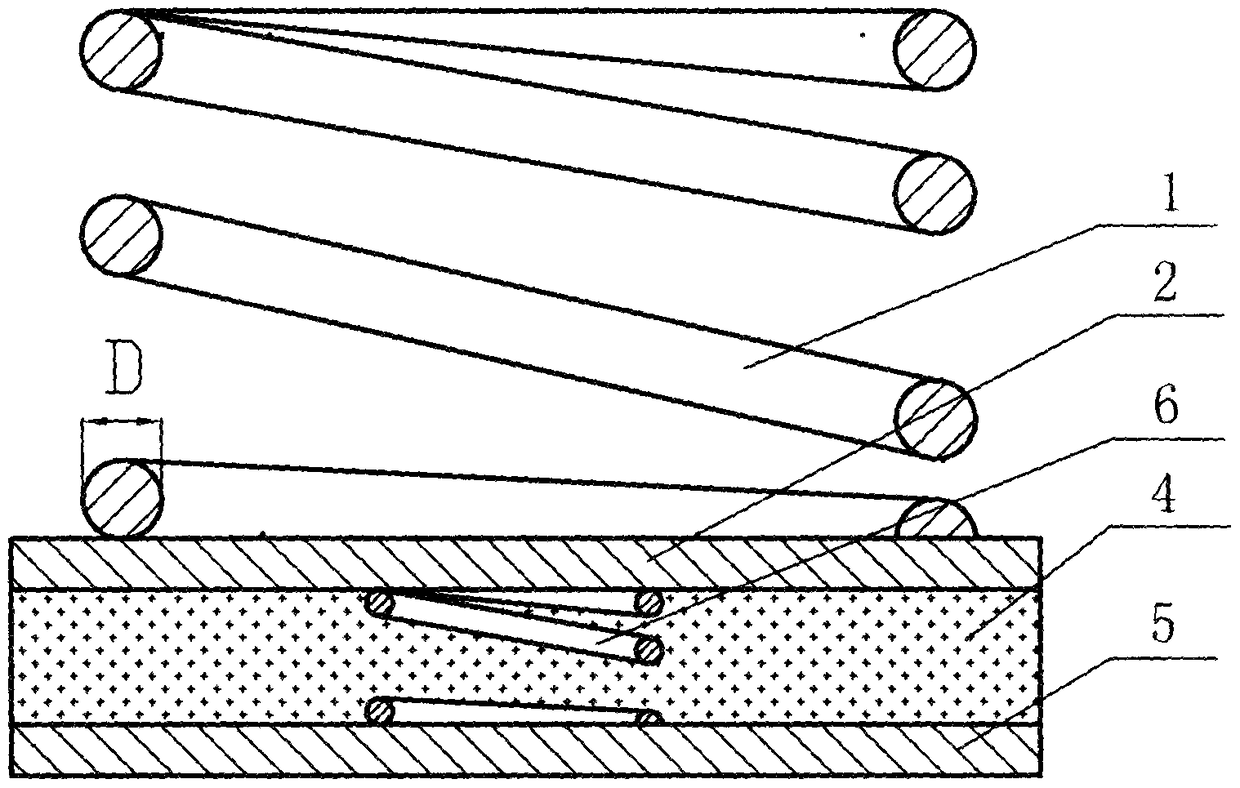

[0010] Such as figure 2 As shown, the principle is the same as that of Embodiment 1, except that the soft elastic organic matter 3 is replaced by a rigid spring 6, and the others remain unchanged.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a sound insulation cushion which comprises an upper load-supporting seat, an elastic body, fiber cotton batting and a lower load-supporting seat and takes the fiber cotton batting and the elastic body as a sound insulation cushion body. A load-supporting spring on a vehicle transfers load to the upper load-supporting seat, the upper load-supporting seat divides the load into two paths and transfers the load, one path of the load is transferred to the elastic body, the other path of the load is transferred to the fiber cotton batting, and the lower load-supporting seat receives the load transferred from the elastic body and the fiber cotton batting. According to the sound insulation cushion, the elastic body and the fiber cotton batting parallelly bear all load force. The elastic body shares part of the load force, the fiber cotton batting no longer deforms when the load force shared by the elastic body and load force for continuing deformation of the fiber cotton batting are balanced, so that the whole sound insulation cushion can bear large load force and can also effectively function in sound insulation and cushioning.

Description

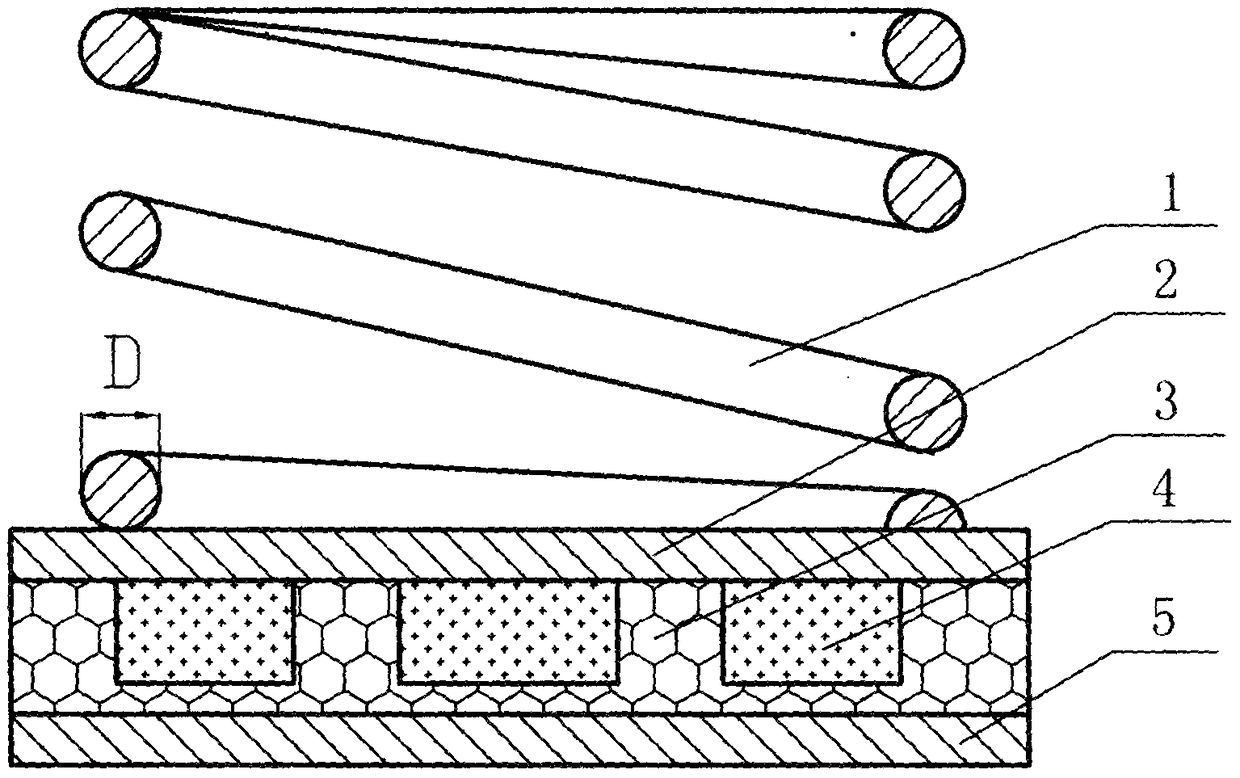

technical field [0001] The invention relates to a sound-insulating and shock-absorbing pad, in particular to a sound-insulating and shock-absorbing pad for a vehicle. Background technique [0002] The existing sound-proof and shock-absorbing pads with a certain load-bearing capacity are basically directly placed on or under the spring by rubber. This method has the disadvantages of poor sound-proof and shock-absorbing effect and easy failure. Contents of the invention [0003] In order to overcome the above-mentioned shortcomings in the prior art, the present invention provides a load-bearing sound-insulating and shock-absorbing pad, which is durable and has good sound-insulating and shock-absorbing effects. [0004] The technical solution adopted in the present invention is: a sound-insulating and shock-absorbing pad composed of an upper bearing seat, an elastic body, fiber batting, and a lower bearing seat, with fiber cotton and elastic body as the main body of sound ins...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16F7/104F16F7/116

CPCF16F7/104F16F7/116

Inventor 廖增强

Owner 廖增强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com