Water level detecting device and steaming box

A technology of water level detection and box body, applied in the field of steam box, can solve problems such as affecting the work of the float and the failure of the steam box to work normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

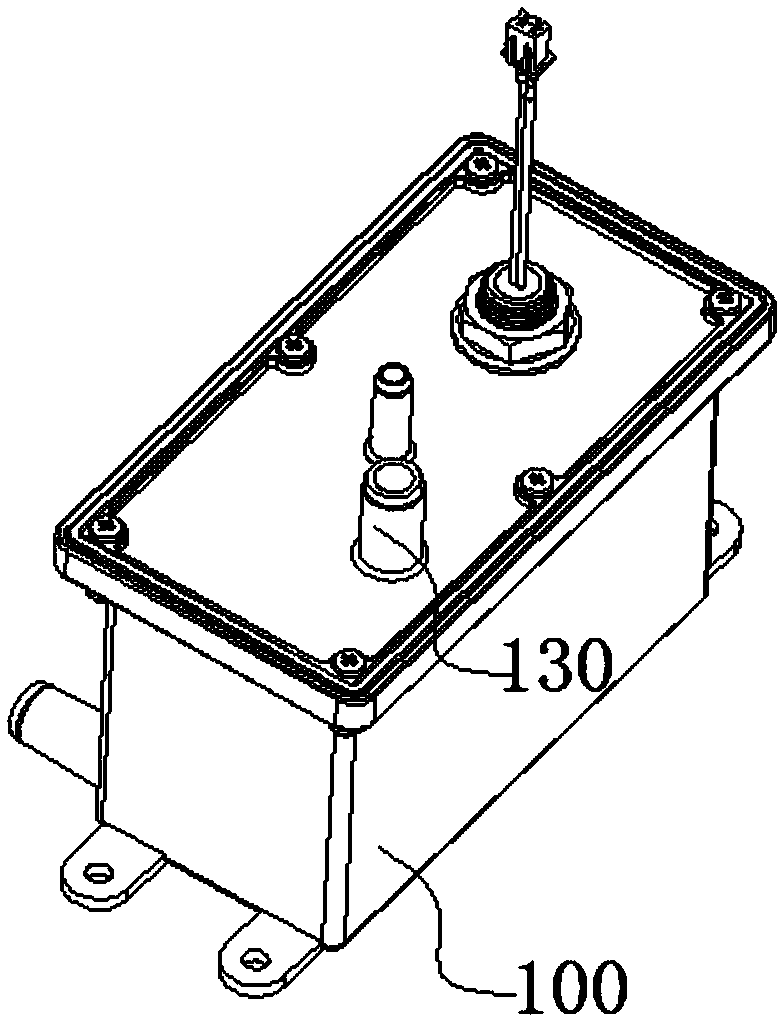

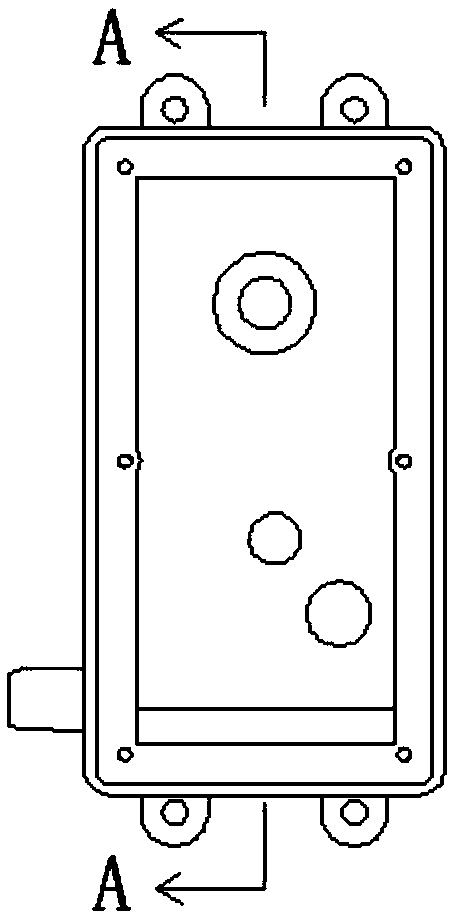

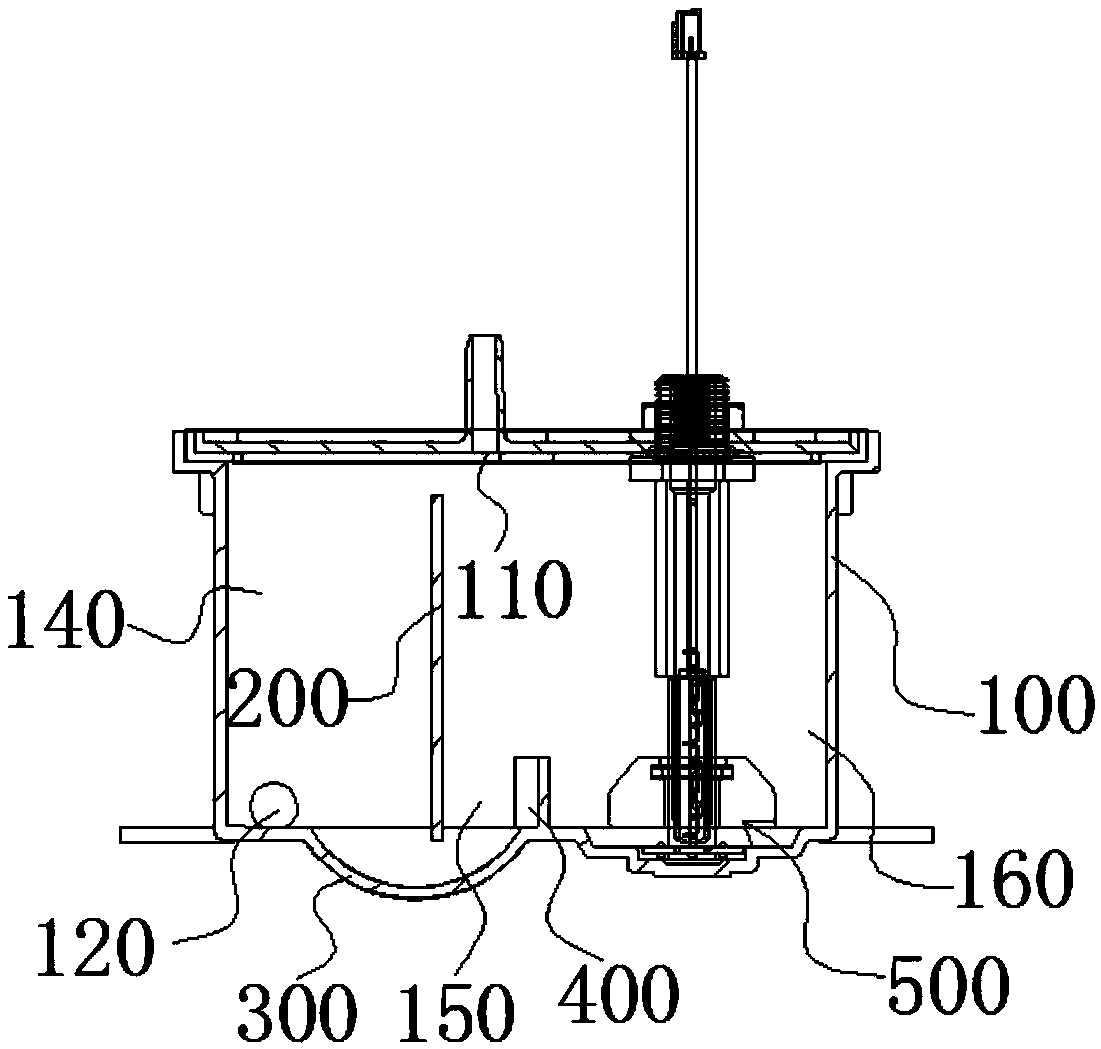

[0045] Such as Figure 1 to Figure 5 As shown, the first embodiment provides a water level detection device, including: a box 100, a water inlet 110 for supplying water to the box 100, and a baffle fixed in the box 100; the baffle separates the box 100 It is at least two areas that are connected, wherein, one area is provided with a water outlet hole 120 for supplying water to the steam generating unit 700, and the other area is provided with a float assembly 500 for detecting the liquid level; wherein, the steam generating unit 700 It is connected with the water level detection device through the principle of a connector, and the baffle is used to prevent grease from entering the area where the float assembly 500 is located.

[0046] In this water level detection device, a baffle plate is added in the box body 100, wherein the baffle plate divides the box body 100 into at least two areas, and since each area is connected to each other, the water between the areas can flow mut...

Embodiment 2

[0068] Such as Figure 1 to Figure 6 As shown, the second embodiment provides a steamer, including: the water level detection device in the first embodiment above.

[0069] The steamer includes the above-mentioned water level detection device, wherein the specific structure, connection relationship and beneficial effects of the water level detection device have been described in detail in the above text, and will not be repeated here.

[0070] Such as Figure 6 and Figure 7 As shown, there is a pipe 800 communicating between the water outlet hole 120 and the steam generating unit 700; the pipe 800 has a second recess 810 communicating with its lumen and used to store oil; wherein, the pipe 800 and the second recess 810 are integrally formed.

[0071] In this structural form, when the oil is flowing back, due to the setting of the second recess 810 , a dense oil mixture will be deposited here.

[0072] Wherein, the pipeline 800 can be a silicone tube.

[0073] In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com