An automatic tester for the flexibility of plastic bellows used in prestressed concrete bridges

A technology for concrete and bridges, applied in the field of plastic bellows detection for prestressed concrete bridges, can solve the problems of high labor intensity for inspectors, inaccurate test results, low degree of automation, etc., to achieve automatic detection, simple structure, and human resources The effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

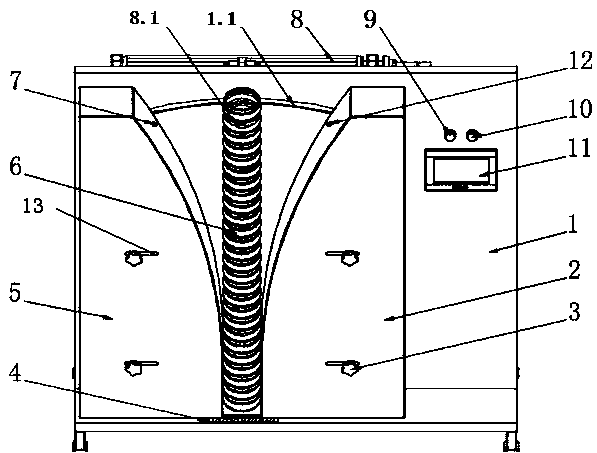

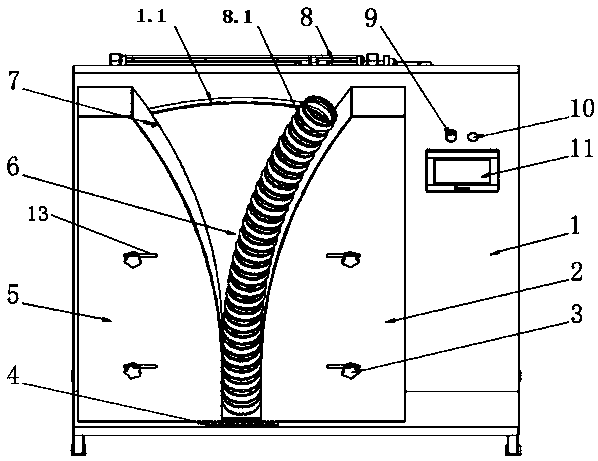

[0034] see Figure 1-3 , an automatic plastic bellows flexibility tester for prestressed concrete bridges, comprising a detection pedestal and a motion module 8; the motion module 8 is arranged on the detection pedestal;

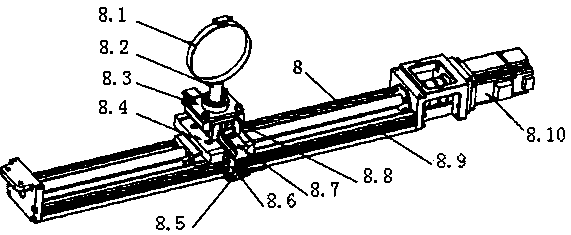

[0035] The movement module 8 includes a transverse movement module, a longitudinal movement module, a rotation module and a clamp (preferably, the clamp is a hoop 8.1); the transverse movement module and the longitudinal movement module are stacked, and the The rotation module is arranged on any one of the lateral movement module or the longitudinal movement module, and the hoop 8.1 is arranged on the rotation module; through the combination of the transverse movement module, the longitudinal movement module and the rotation module, the hoop 8.1 carries corrugated Pipe 6 makes left and right bending motions.

[0036] The transverse movement module is arranged horizontally on the detection platform, the longitudinal movement module is arranged longitudinally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com