A method for judging the depth of non-conductor defects based on multi-pair electrode capacitive imaging detection technology

A technique of capacitive imaging and multiple pairs of electrodes, which is applied to measuring devices, material analysis through electromagnetic means, instruments, etc., can solve problems such as long time, low efficiency, and inaccurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

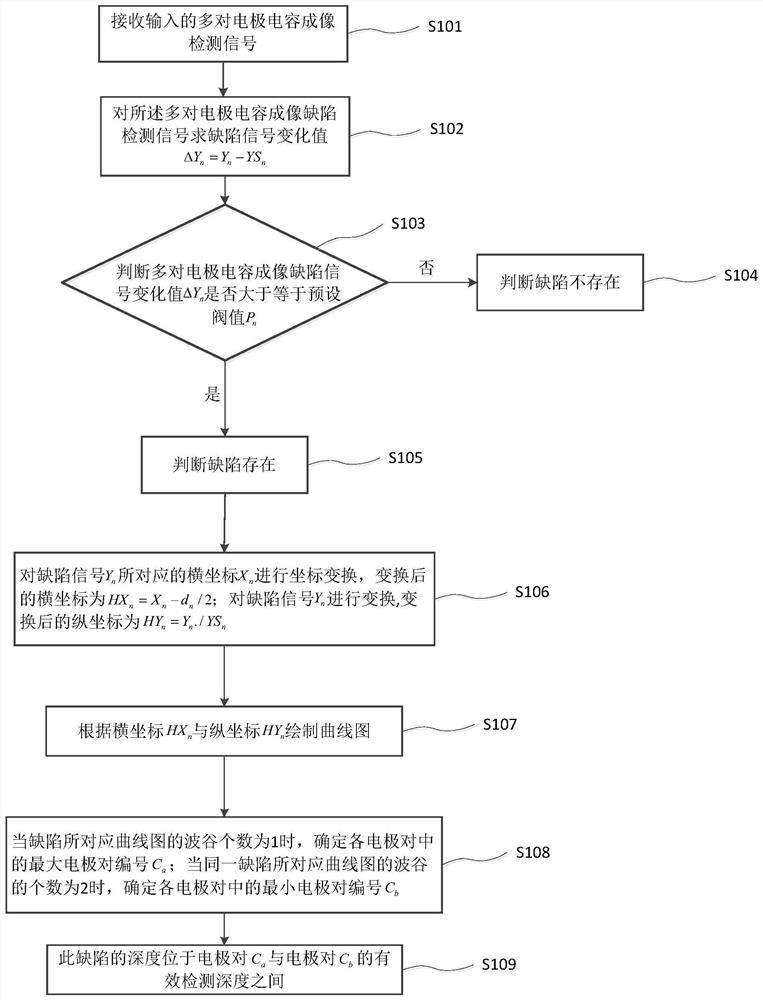

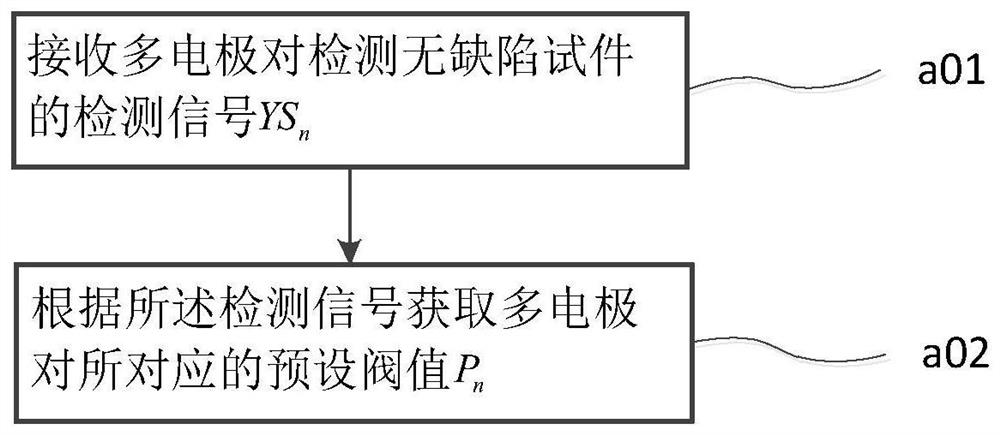

[0018] figure 1 A method of discriminating a non-conductor defect depth based on multi-pair electrode capacitance imaging detection techniques Figure one As shown in the figure, including:

[0019] S101, receive the input multi-pair electrode capacitively imaging detection signal, wherein the plurality of pairs of electrode capacitively imaging detection signals comprise each electrode pair under the height L (C 1 , C 2 ... C n ) On detection signals containing defective test pieces (Y 1 Y 2 , ... y n ) And each electrode pair under the same reduction height L (C 1 , C 2 ... C n ) Test signal for the same material without defect test piece (YS 1 YS 2 , ... ys n ).

[0020] Specific, signal and mathematical processing software receive input detection signals, wherein the detected detection signal is the detection signal input by multi-pair of electrode capacitance imaging detecting probe inputs, and the detection signal contains a reduction height L. Each electrode pair (C 1 , C 2...

Embodiment 2

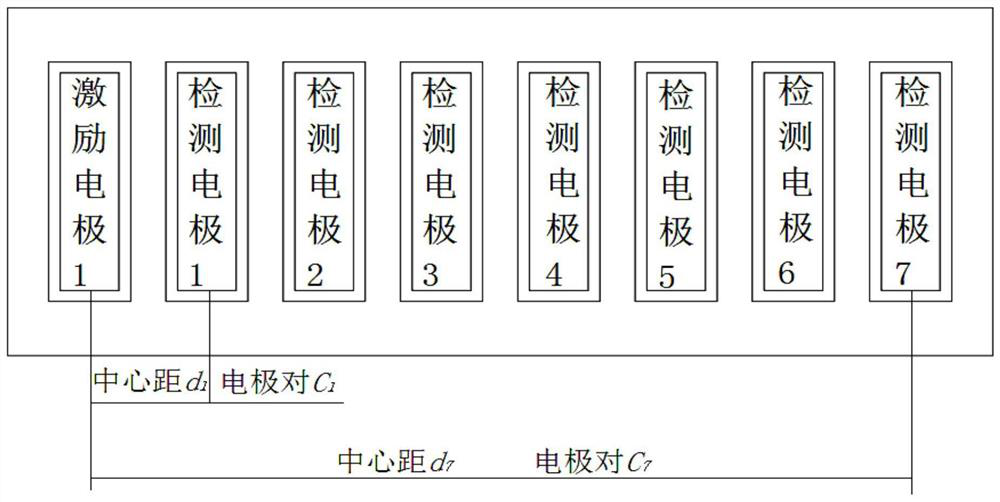

[0031] A method of discriminating a non-conductor defect depth based on a multi-pair of electrode capacitance imaging detecting techniques, which gives an experiment, which is a specific value of the multi-electrode plate (for example, N = 7, not cumbersome). Implementation method to verify the effectiveness of the method.

[0032] The reception detection probe (eg image 3 The input of the input sheet of the input is pair (C) of each electrode pair at 2 mm (C 1 , C 2 , C 3 , C 4 , C 5 , C 6 , C 7 ) Contains defective test piece (such as Figure 4 The detection signal shown) (Y 1 Y 2 Y 3 Y 4 Y 5 Y 6 Y 7 ) And each electrode pair under the same reduction height L = 2 mm (c 1 , C 2 , C 3 , C 4 , C 5 , C 6 , C 7 ) Test signal for the same material without defect test piece (YS 1 YS 2 YS 3 YS 4 YS 5 YS 6 YS 7 ); According to the multi-electrode pair (C 1 , C 2 , C 3 , C 4 , C 5 , C 6 , C 7 ) Detect detection signals without defective test pieces (ys 1 YS 2 YS 3 YS 4 YS 5 YS 6 YS 7 ) Get...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com