A photoionization detector system

A photoion detection and light source technology, applied in the field of photoion detection, can solve problems such as inconvenient calibration of photoion detectors, and achieve the effect of reducing labor costs and system downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

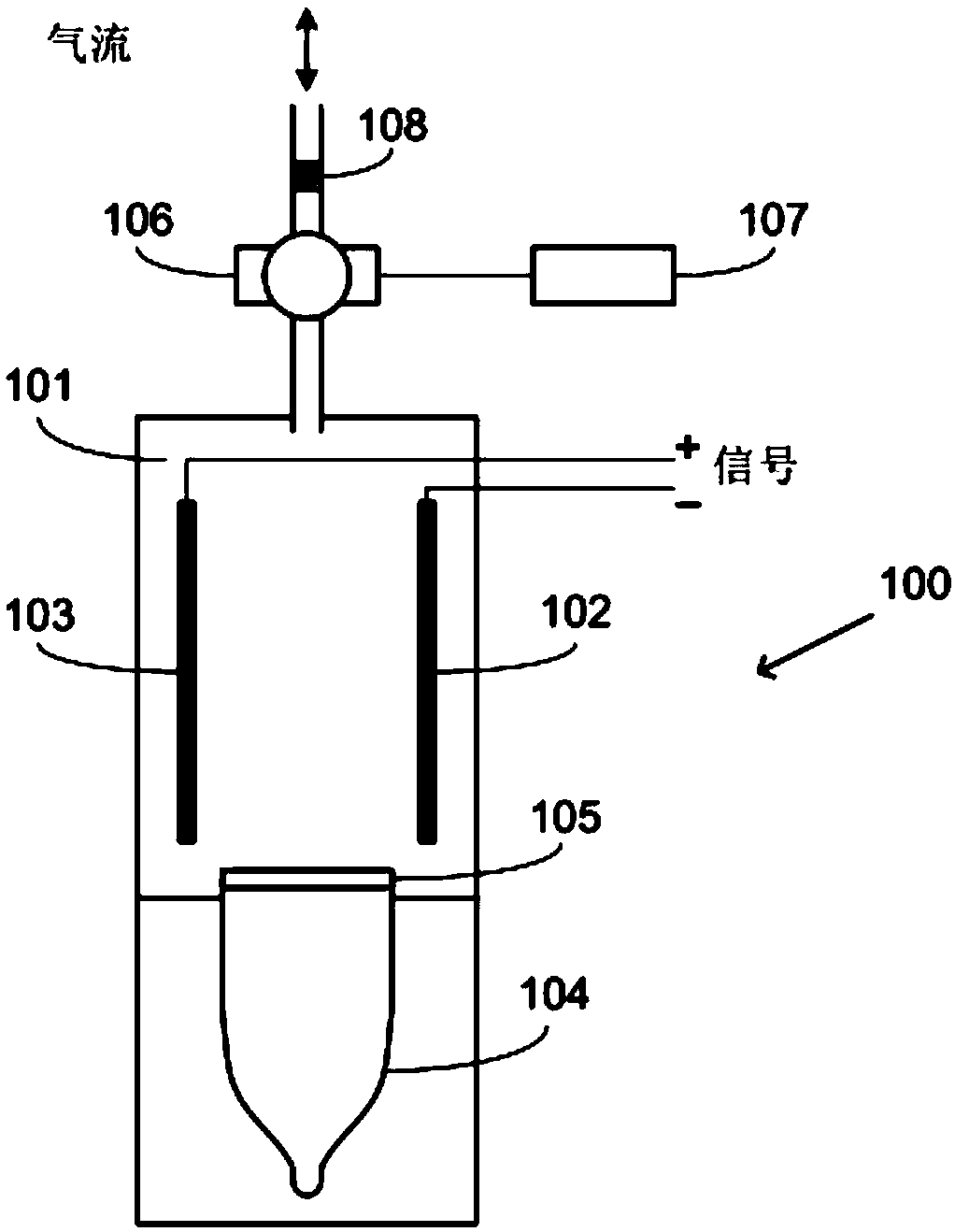

[0041] like figure 1 As shown, a PID system 100 based on the prior art has a measuring gas chamber 101, electrodes 102 and 103, a UV light source 104, a UV light window 105, an air pump module 106, a controller 107 and a dust filter 108 . The air pump module 106 is controlled by the controller 107 . A dust filter 108 is used to remove dust particles from the gas to be measured. Arrows show airflow direction at different times. The gas pump module 106 draws gas into the gas chamber 101 before the measurement begins. After that, the ultraviolet light source 104 is turned on, the gas molecules in the gas chamber are ionized, and electrical signals are monitored via the electrodes 102 and 103 . When performing the measurement of volatile organic compounds, air from the outside environment is pumped into the air chamber 101 . When the calibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com