Circuit board turning over tool

A technology for circuit boards and jigs, which is applied in the field of circuit board flipping jigs, can solve problems such as inability to recycle, fail to meet the rapid production of enterprises, waste resources, etc., and achieve the effects of improving production efficiency, avoiding bending, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

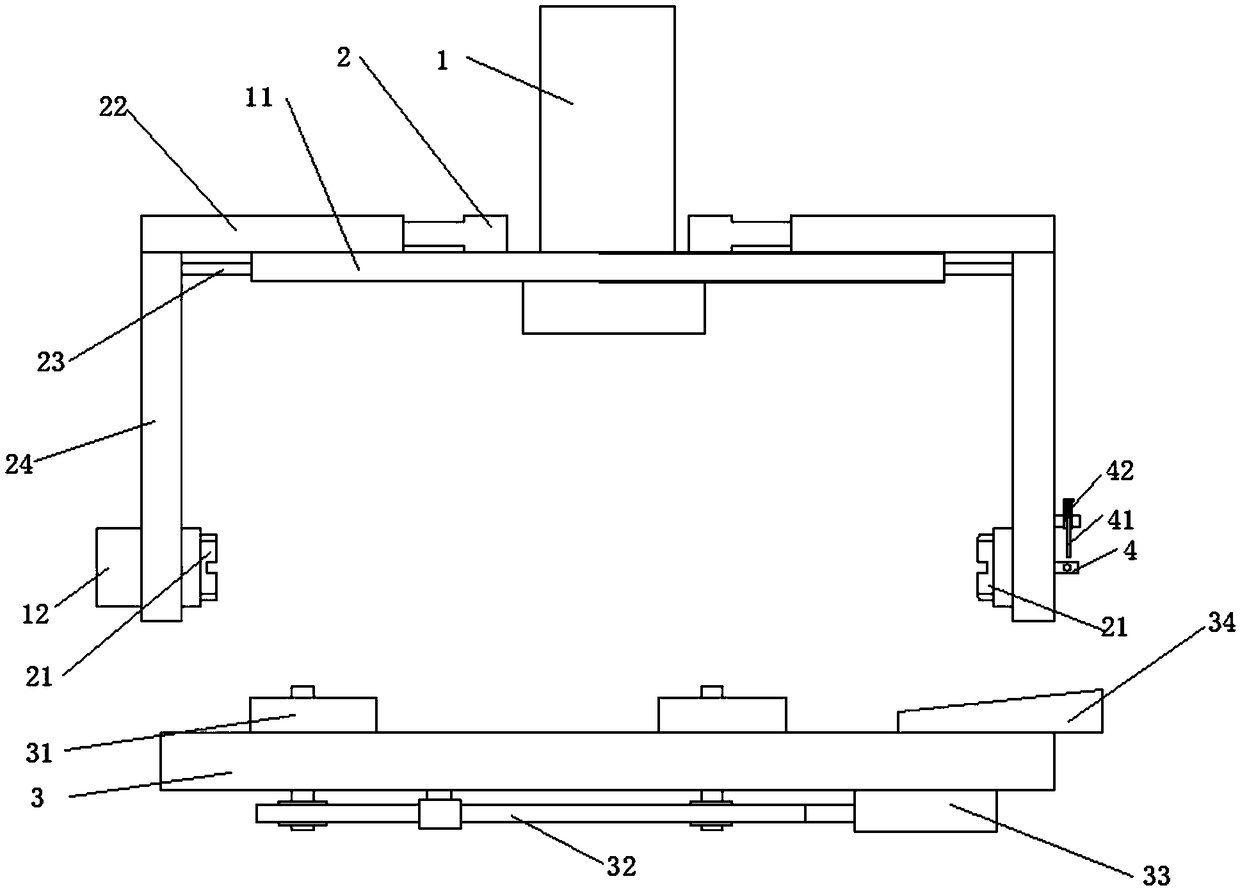

[0019] refer to figure 1 , a circuit board turning jig, including a turning grip and a positioning jig, the turning grip is set directly above the positioning jig, the turning grip is set on the lifting drive part 1, the The lifting drive part 1 drives the turning handle to move up and down. The positioning fixture includes a fixture plate 3 and a plurality of positioning components for positioning the circuit board. The positioning components are arranged on the fixture plate 3. The jig plate 3 is provided with grooves for shielding circuit boards or electronic components. The positioning component is connected to a positioning driving component, and the positioning driving compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com