Fishpond feed putting device

A feeding machine and fish pond technology, applied in the field of agricultural machinery, can solve problems such as increased production costs, motor damage, and potential safety hazards, and achieve the effects of reduced maintenance, equipment safety, and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further illustrate the technical means adopted by the present invention and the technical effects achieved, the following will be described in detail in conjunction with the accompanying drawings and embodiments.

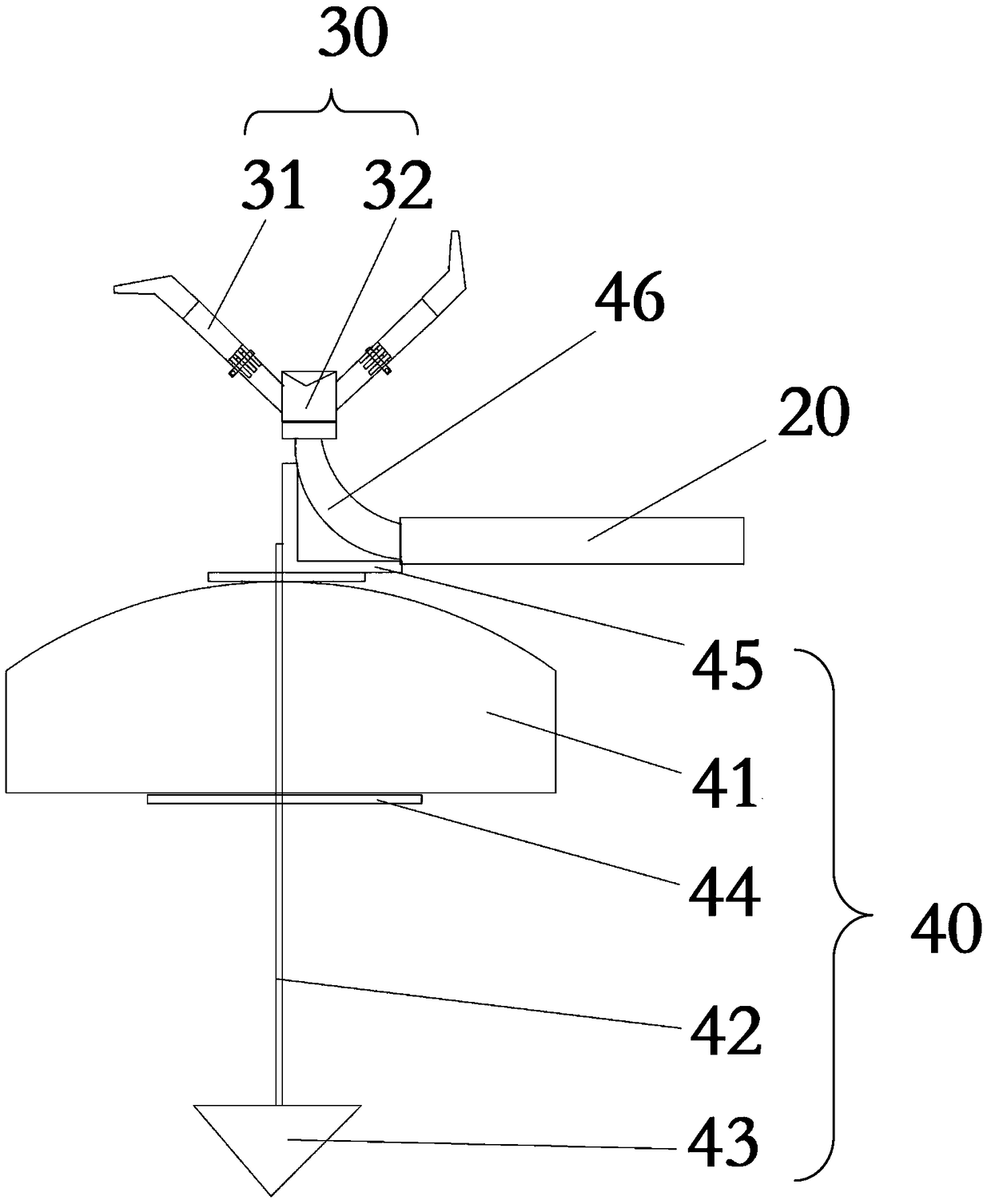

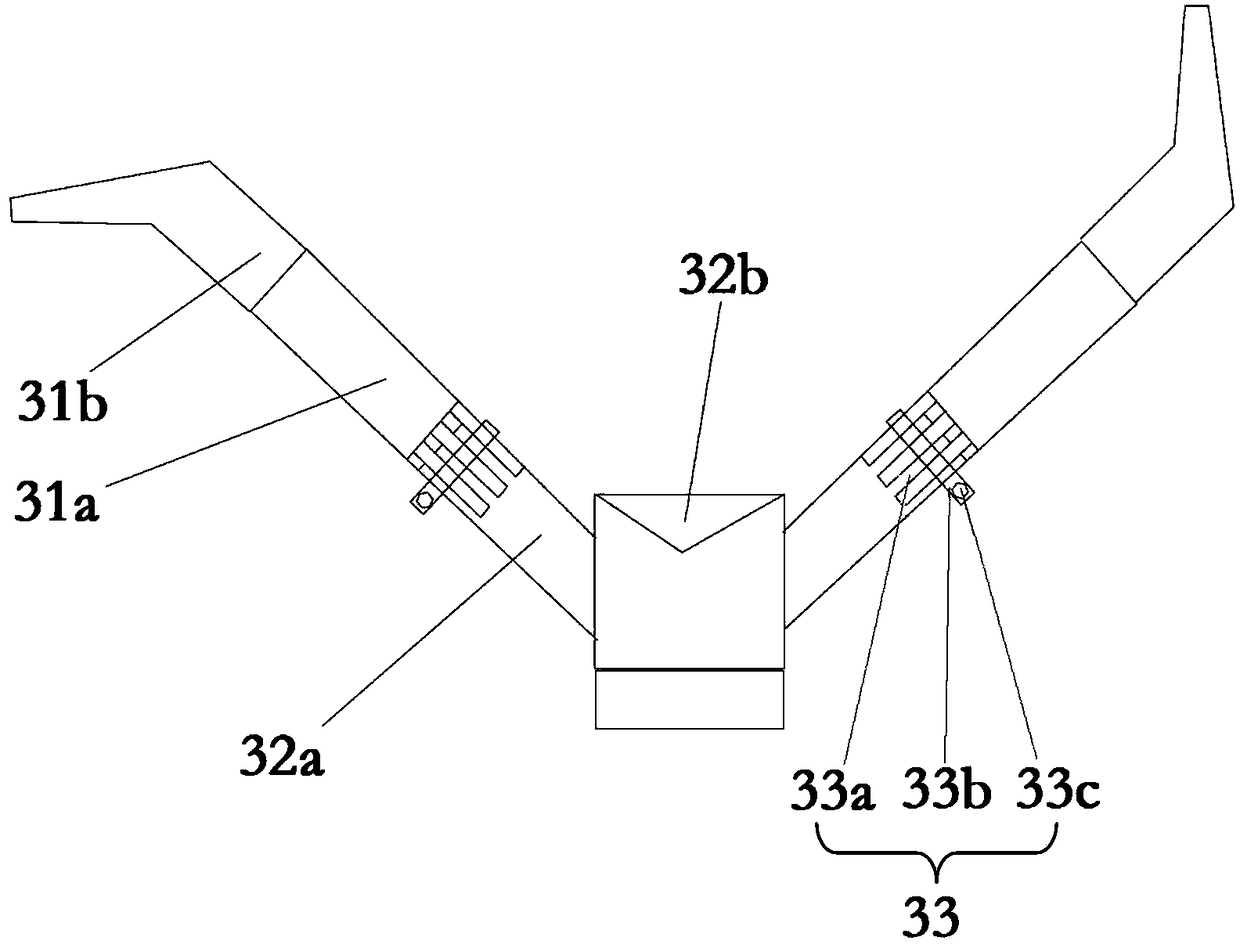

[0024] refer to figure 1 with figure 2 , is the feeder for fish ponds according to the present invention, which includes a feed pipe 20 , a spray head 30 , and a tumbler floating ball structure 40 . In one embodiment, the spray head 30 includes a spray nozzle 31 and a main pipe 32, the spray nozzle 31 includes a fixed pipe 31a and an air guide elbow 31b, one end of the fixed pipe 31a is connected to the The air guide elbow 31b is fixedly connected, and the air guide elbow 31b is an elbow with a radian or an included angle. The diameter of the air guide elbow 31b gradually becomes smaller along the airflow direction. The diameter of the place is half of the diameter of the fixed pipe 31a. The included angle of the wind guiding elbow 31b is pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com