Improved method used for producing detergent composition particle

A composition and detergent technology, applied in the directions of detergent powder/flake/sheet, chemical instrument and method, mixer, etc., can solve the problems of long mixing time, low degree of automation use, cumbersome operation steps, etc. Convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

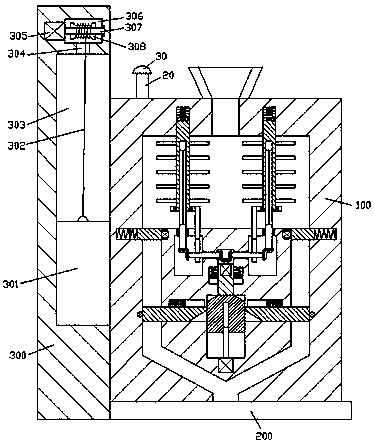

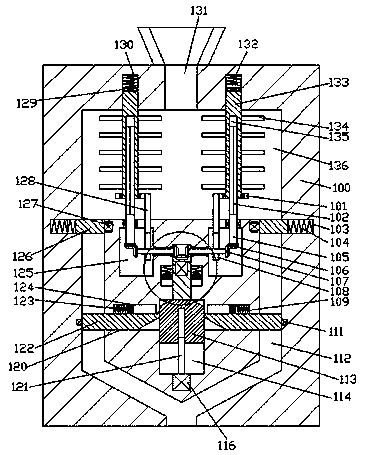

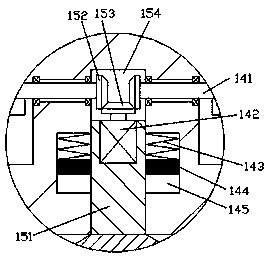

[0016] Combine below Figure 1-3 The present invention will be described in detail.

[0017] refer to Figure 1-3, an improved method for producing detergent composition granules according to an embodiment of the present invention, which uses a device for producing detergent composition granules, the one for producing detergent composition granules The equipment includes an outer casing 100 mounted on the right side of the support frame 300 through a lifting element and a base plate 200 fixedly installed on the bottom right side of the support frame 300. The top end surface of the outer casing 100 is poured into the groove 131, so The bottom end of the pouring groove 131 is connected with a stirring chamber 136, and the inner bottom wall of the stirring chamber 136 is symmetrically provided with a first sliding chamber 130, and the first sliding chamber 130 is rotated and fitted with a The first rotary rod 133 in the stirring chamber 136, the top end of the first rotary rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com