Test tube cleaning device

A cleaning device and test tube technology, which is applied in the field of chemical experiments, can solve the problems of inability to realize the integration of test tube cleaning and drying, lack of mechanical friction cleaning process, and inability to guarantee cleaning quality, so as to facilitate use and promotion, avoid personal injury, Use a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

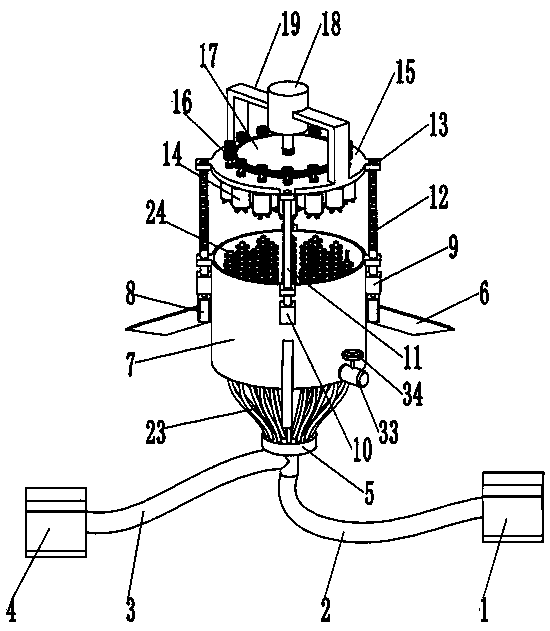

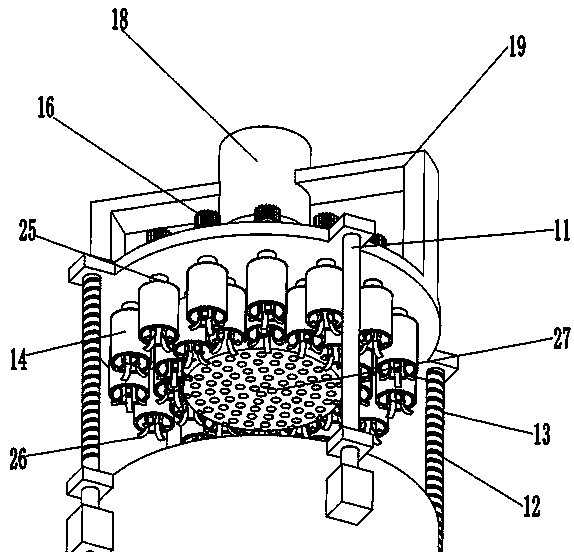

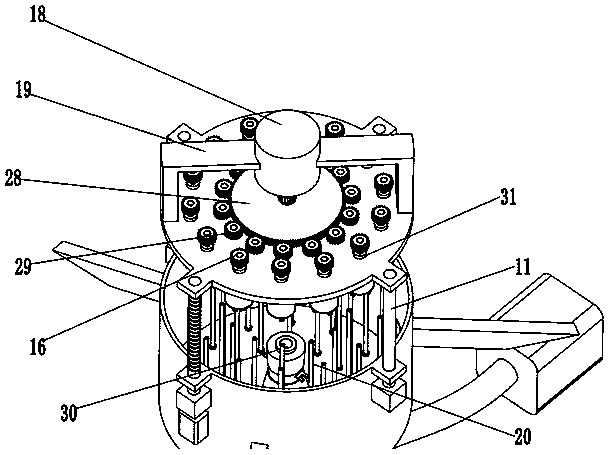

[0030] Embodiment 1: as Figure 1-5As shown, the test tube cleaning device includes an air supply device 1, a vent pipe 2, a water pipe 3, a water supply device 4, a water separator 5, a stable frame 6, a washing tank 7, a stepping motor I 8, a bearing seat 9, and a fixing member 10 , polished rod 11, screw rod 12, slider 13, test tube holder 14, platform 15, pinion gear Ⅰ 16, large gear Ⅰ 17, stepping motor Ⅱ 18, support frame 19, water diversion hose 23, cleaning column 24, large gear Ⅱ28, pinion Ⅱ29; the air supply device 1 communicates with the positive hole at the lower end of the water separator 5 through the air pipe 2, the water supply device 4 communicates with the side hole at the lower end of the water separator 5 through the water pipe 3, and the upper end of the water separator 5 The hole communicates with one end of the water diversion hose 23, and the other end of the water diversion hose 23 communicates with the bottom of the washing tank 7, and communicates wi...

Embodiment 2

[0031] Embodiment 2: The device structure of this embodiment is the same as that of Embodiment 1. The difference is that a transducer 30 is arranged at the center of the washing tank 7, and three stabilizing frames 6 are evenly arranged outside the washing tank 7; the test tube cleaning device also includes a single-chip microcomputer, step The feeder motor Ⅰ, stepper motor Ⅱ, gas supply device and water supply device are respectively connected to the power supply through a single-chip microcomputer (89C51 series) to control the switch.

[0032] During use, first some test tubes with stains or chemical residues are buckled upside down on the cleaning column 24, the water supply device 4 is opened, the air supply device 1 is closed, and the water enters the water separator 5 through the water pipe 3; one end of the water distribution hose 23 It is connected with the water separator 5, and the other end is connected with the cleaning column 24. The water separator distributes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com