Ceramic tile texture pattern producing device

A ceramic tile and texture technology, applied in the field of ceramic tile production, can solve the problems of difficult installation, blank body, easy blockage of nozzles of inkjet printers, etc., and achieves good economic benefits and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

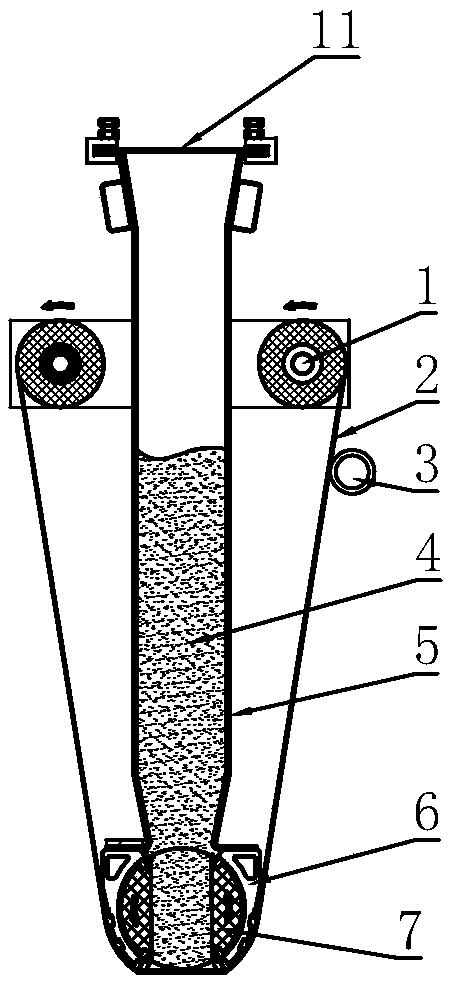

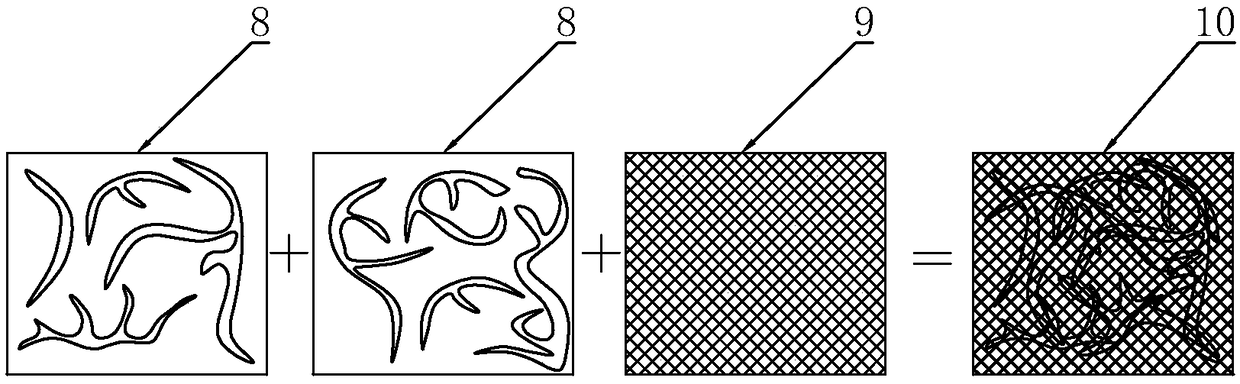

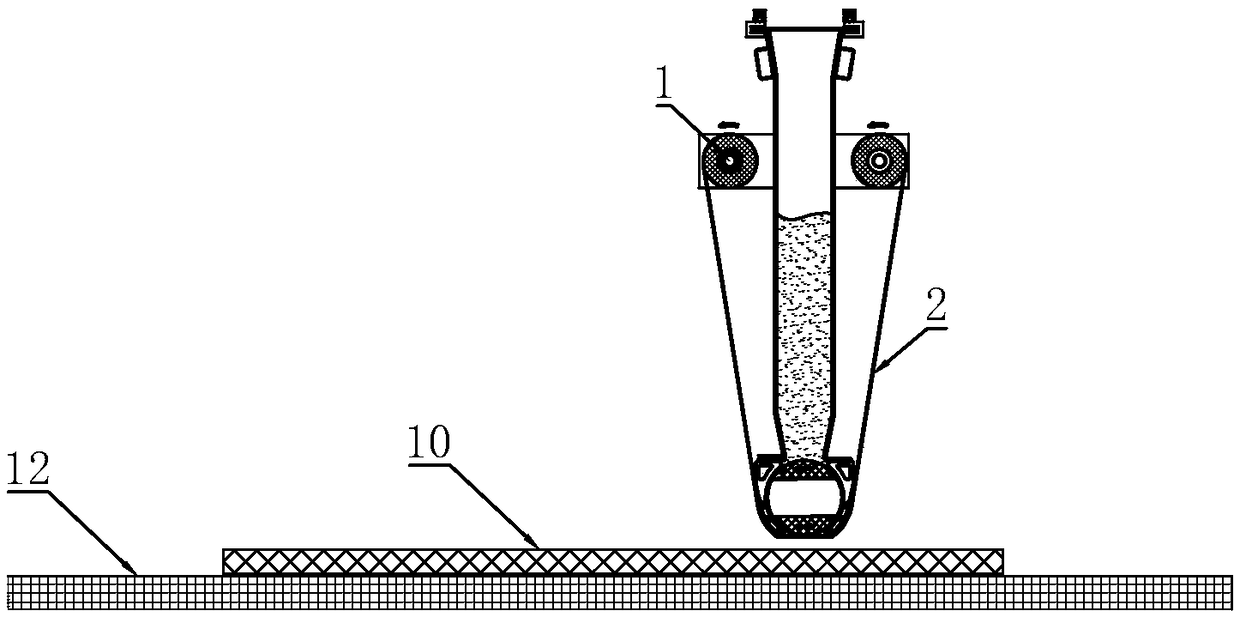

[0019] refer to Figure 1 to Figure 3 , a ceramic tile texture pattern realization device, comprising a storage hopper mechanism 5, a ceramic powder 4 arranged in the storage hopper mechanism 5, a powder inlet 11 arranged at the top of the storage hopper mechanism 5, the device also includes a The film rotating shaft 1, engraving film 2, encoder 3, roller guard 6, rotary feeding control drum 7 and combined grille 10 on both sides of the hopper mechanism 5, the rotating feeding control drum 7 is arranged on the storage hopper mechanism 5 At the lower end, the drum guard 6 is located outside the rotary feeding control drum 7, and the engraved film 2 passes through the film rotating shaft 1 on the left side of the storage hopper mechanism 5, the lower end of the rotary feeding control drum 7, and the storage hopper mechanism 5 on the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com