A novel mining pipeline snatch device

A pipeline and mining technology, applied in the field of mining pipeline snatch device, can solve the problems of limited pitch angle of the manipulator, unreachable limit position, large space occupation, etc., to improve operability, good versatility, work Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

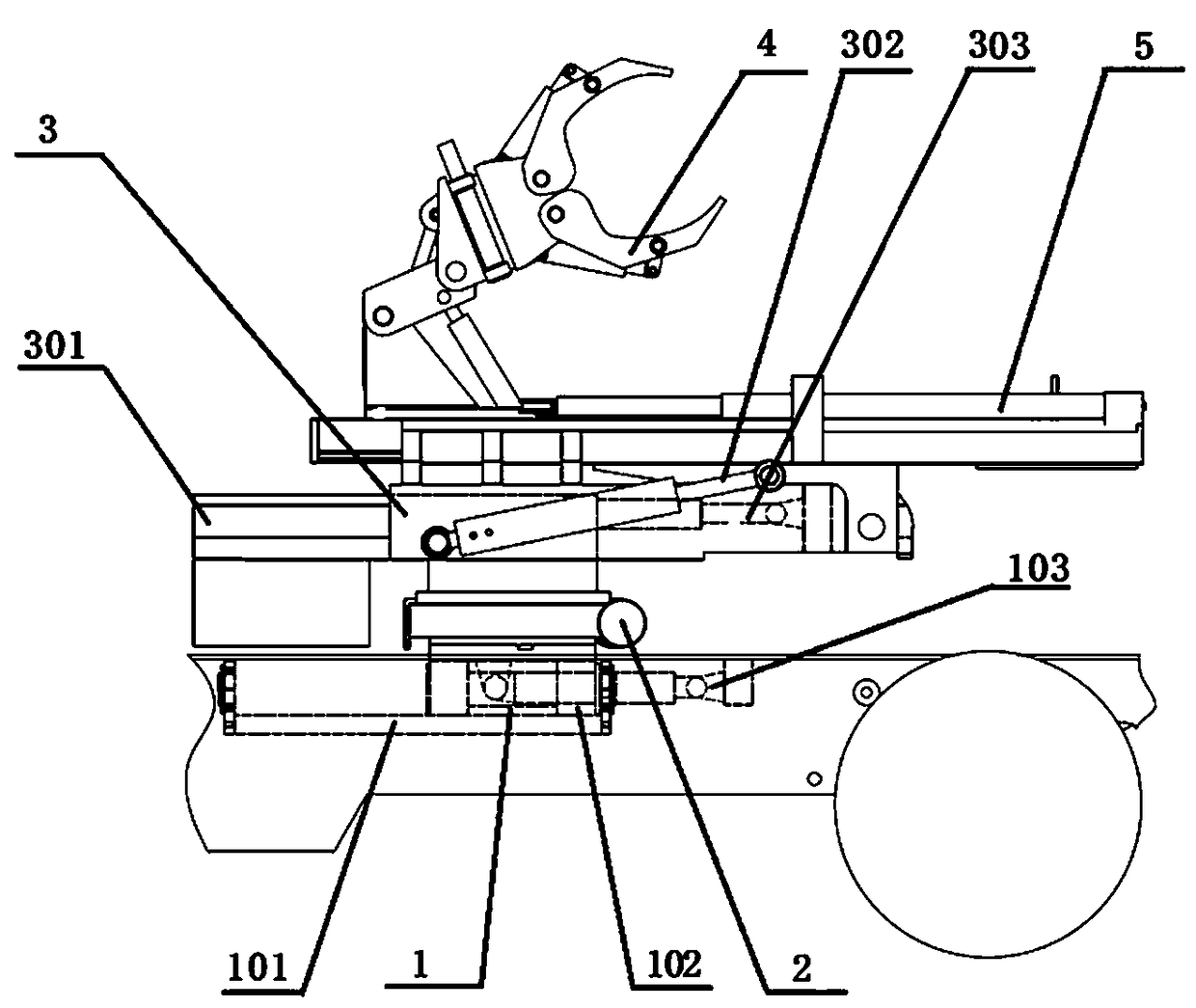

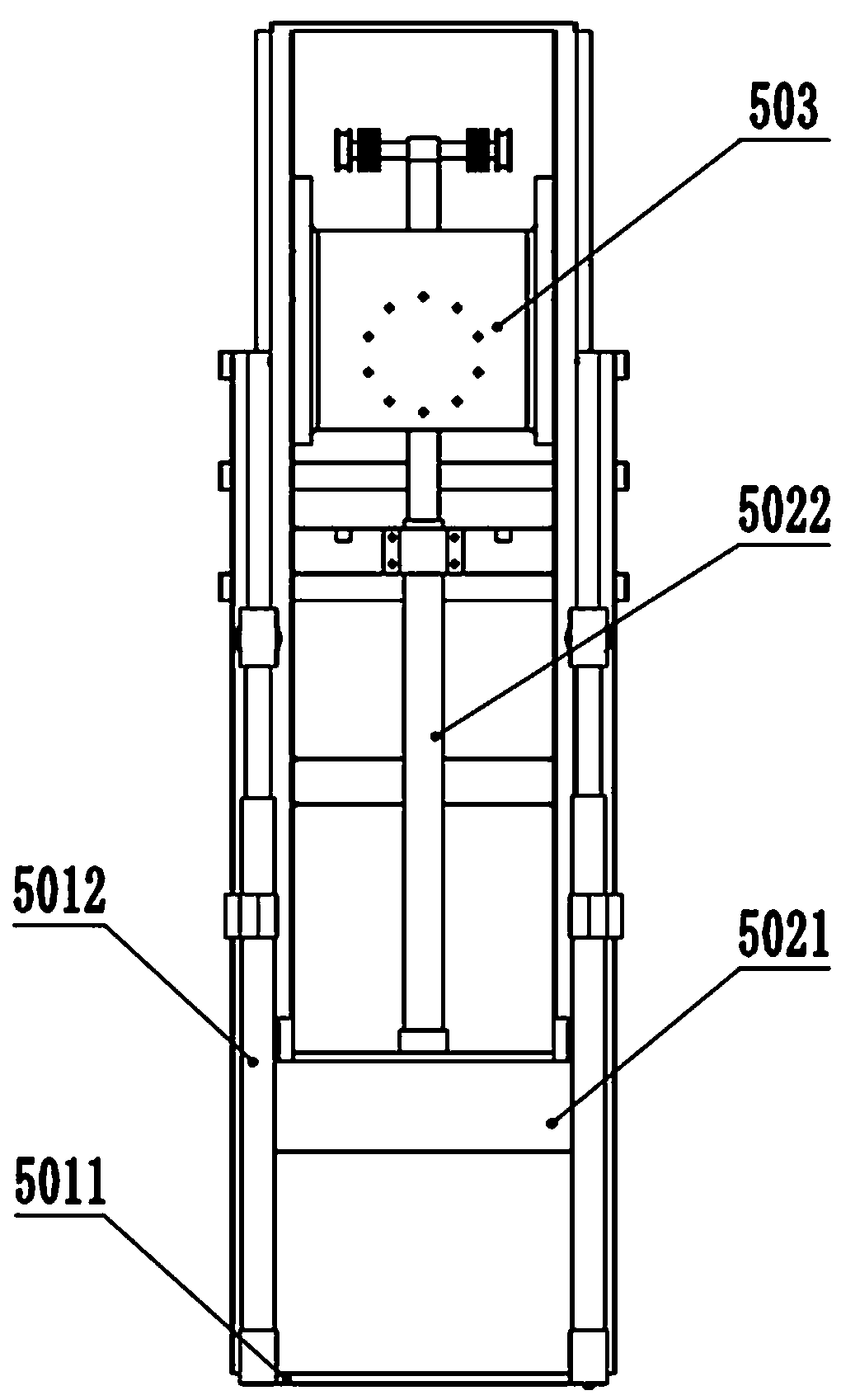

[0034] Such as figure 1 The new mining pipeline snatching device shown is composed of a horizontal movement mechanism, a left and right rotation mechanism, a horizontal telescopic turning mechanism, a hydraulic large-angle manipulator, and a two-stage free-style gantry system.

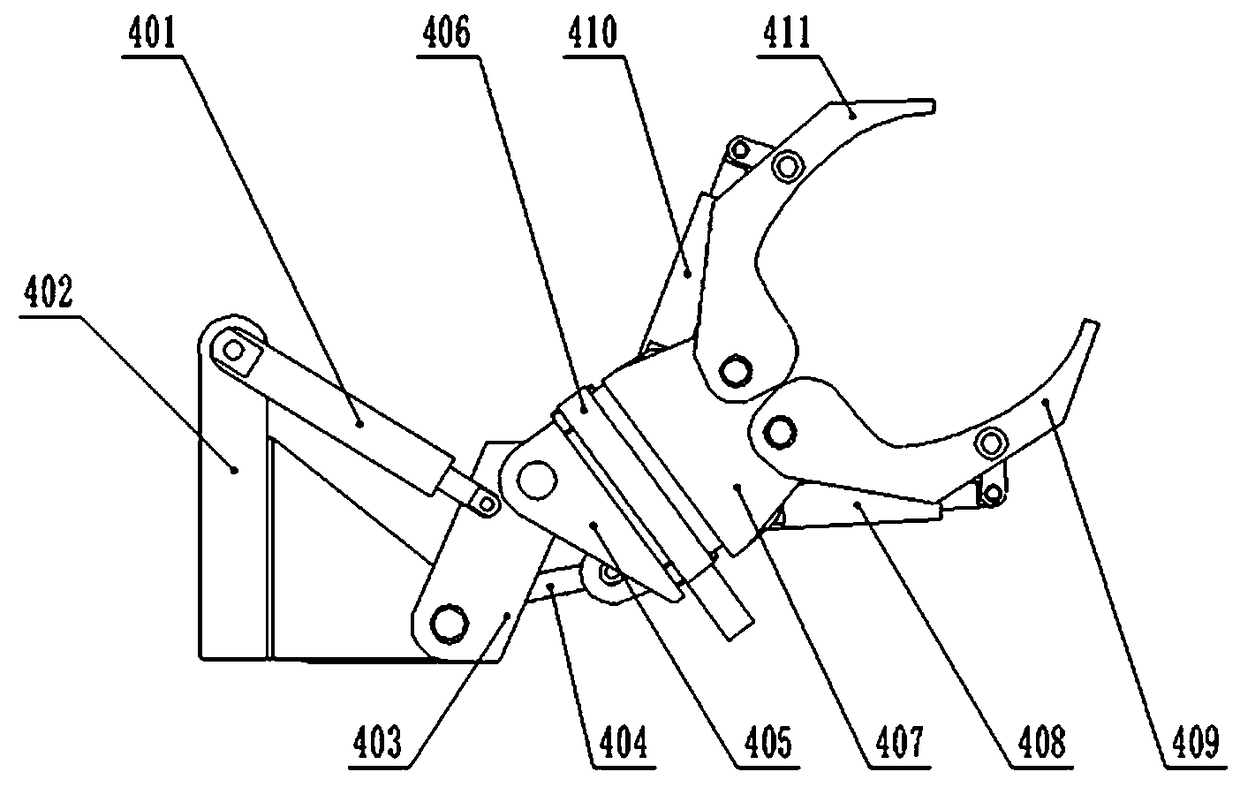

[0035] Hydraulic large-angle manipulator structure such as Figure 4 and 5 As shown, it is composed of a pitching cylinder one, a base, a connecting plate, a pitching cylinder two, a connecting plate two, a slewing support, a manipulator base, a manipulator first cylinder, a gripper one, a manipulator second cylinder, and a gripper two. The base is installed on the whole machine, one end of the pitching cylinder 1 is hinged to the base, and the other end is hinged to the connecting plate 1; one side of the connecting plate is provided with a card slot, and the pitching cylinder 2 is installed in the carding slot, and the two sides of the tank wall Hinged, the other end is hinged with the groove wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com