A detachable electric lifting module

A lifting module and detachable technology, which is applied in the field of lifters, can solve problems such as potential safety hazards, and achieve the effects of convenient operation, improved utilization rate, and improved mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

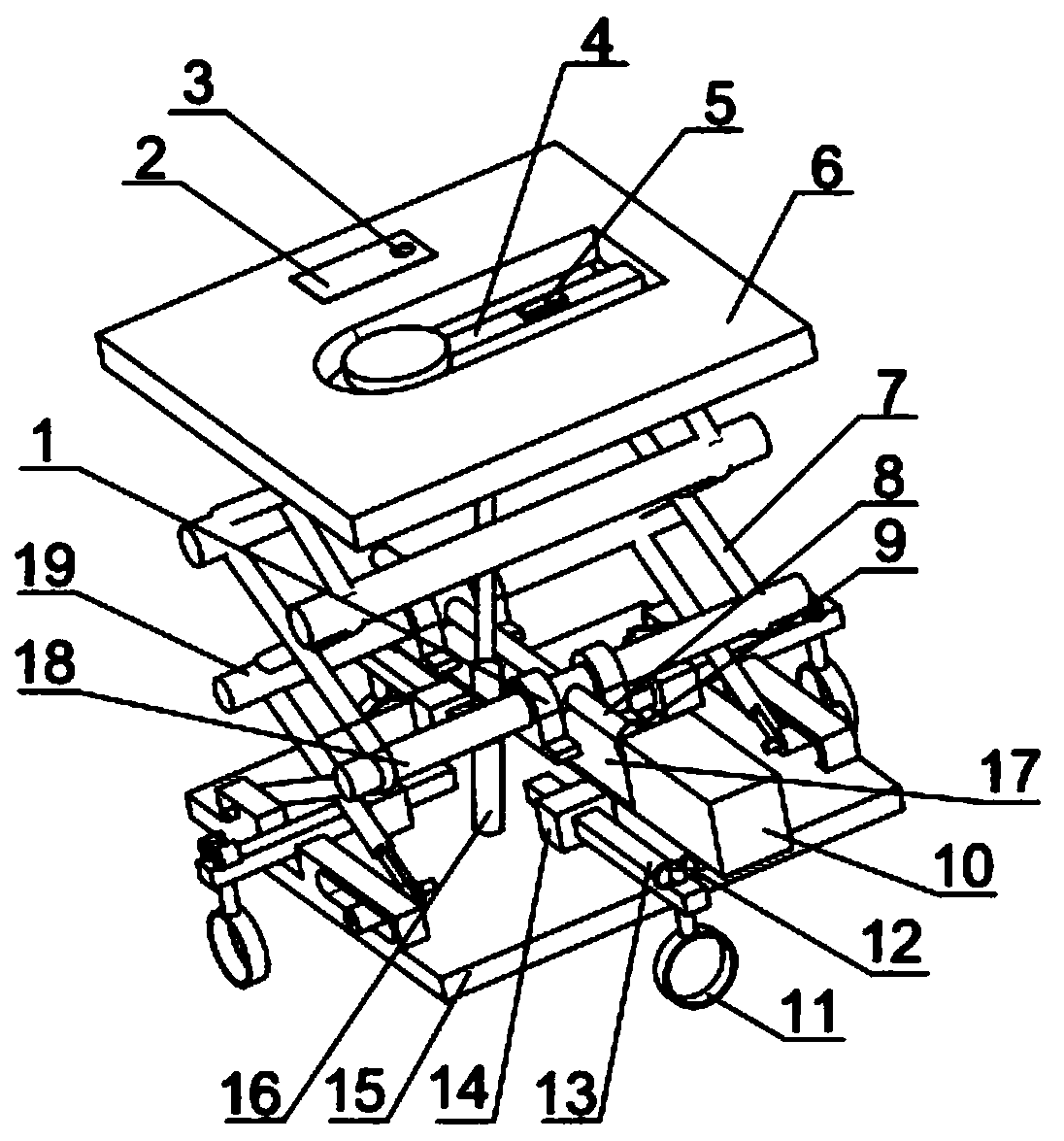

[0028] Such as figure 1 As shown, a detachable electric lift module, including:

[0029] Loading module: used to provide the weight of the object, and has an overweight alarm function;

[0030] Lifting module: used to realize the lifting and lowering of the loading module;

[0031] Fixed module: used to achieve fixed with mobile equipment;

[0032] Energy storage module: used to store the hydraulic energy generated when the object descends, and reduce the bearing capacity of the lifting module;

[0033]The loading module can be set to weigh and display the weight of the cargo. When the loaded cargo is overweight, it has an alarm function, which solves the problem that the fatigue strength of the equipment is reduced or the equipment parts are directly damaged due to the overload of the loaded object during the conventional loading process. The device is fixed on the common means of transportation through the fixing module, such as flatbed or trolley, which is convenient for...

Embodiment 2

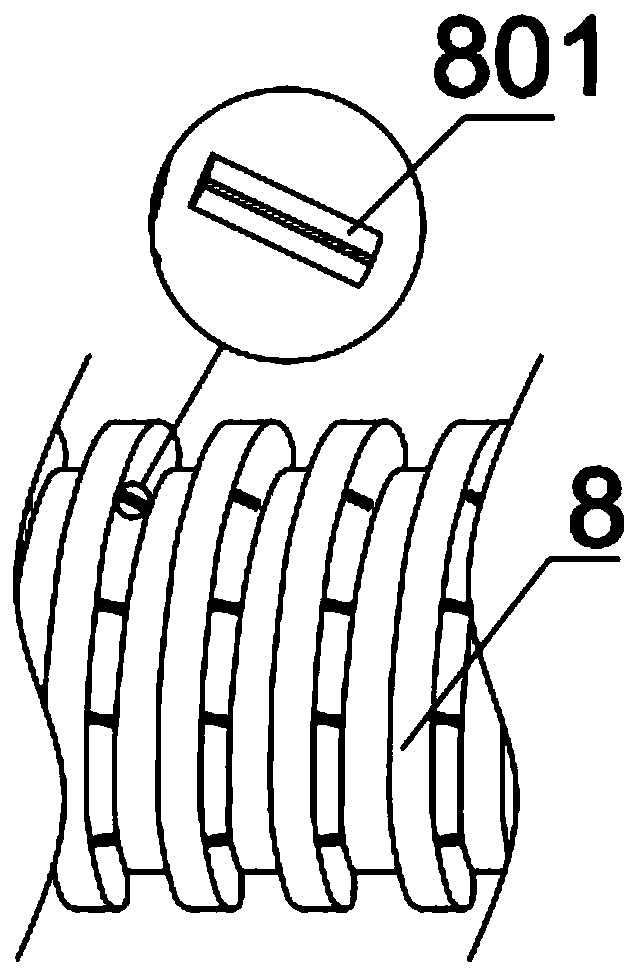

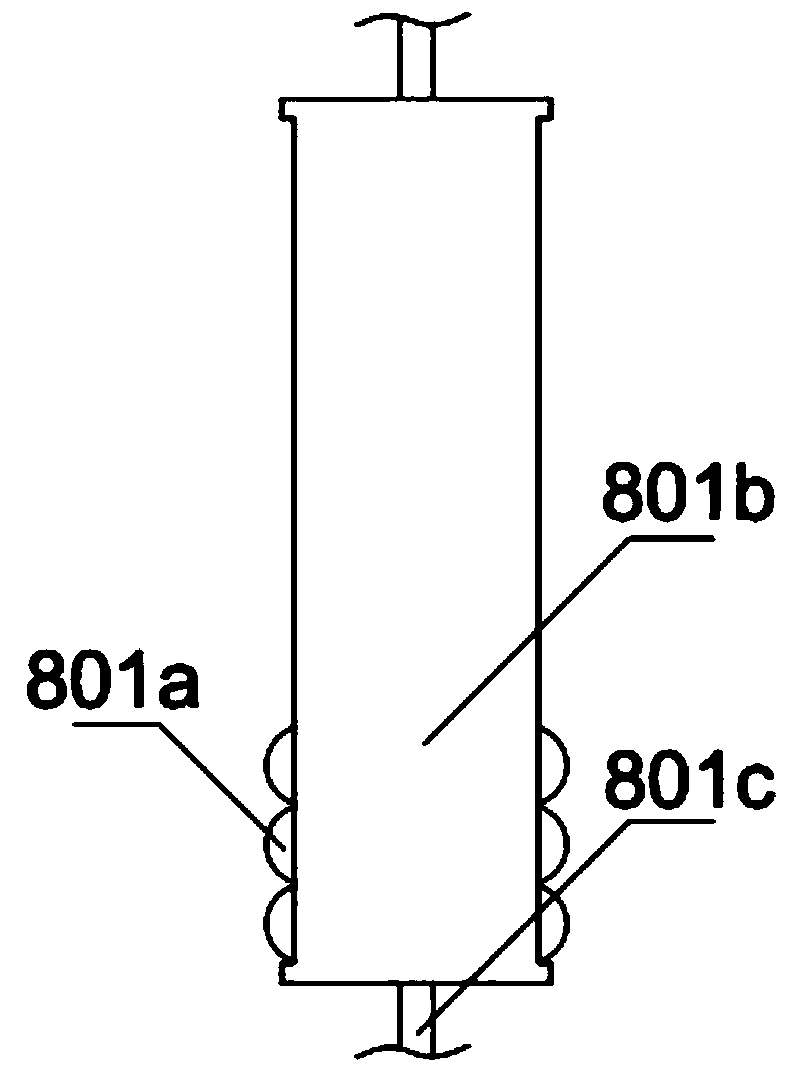

[0040] The further optimization scheme of this embodiment on the basis of embodiment 1 is as follows: Figure 2-4 As shown, the screw 8 is a double-ended trapezoidal threaded screw, and the threaded surface of the screw 8 is evenly distributed with rollers 801 whose axes are perpendicular to the axis of the screw 8. The rotation of the screw 8 can be realized by selecting a double-ended trapezoidal screw. 18a and cross bar 19b make relative movement on the screw rod 8 in a horizontal state, so that the included angle of the scissors 7 changes, and the setting of the roller 801 changes the original trapezoidal thread transmission process. The evenly distributed rollers 801 can make the trapezoidal thread switch between surface contact and line contact during the transmission process, improve the transmission efficiency of the trapezoidal thread, and the transmission is stable, there is no vibration during the transmission process, and it is also beneficial to reduce The amount ...

Embodiment 3

[0044] When a detachable electric lifting module of the present invention is actually used, first connect the device to the trolley, move the guide rail 13 according to the size of the trolley, unscrew the ingot nut 12, the clamp 11 will be untied, and the clamp 11 will be fixed on the Tighten the ingot nut 12 on the corresponding bar of the trolley base to realize the connection between the device and the trolley. When the object is placed on the stage 6, the cantilever frame 4 is under pressure, causing the strain gauge 5 to deform, thereby measuring the torque The signal is transmitted to the single-chip microcomputer, and the single-chip microcomputer processes the data and displays the data through the digital display board 2. When the object is overweight, the buzzer 3 will give an alarm to avoid damage to the goods caused by the damage of the mechanism or the fatigue strength of the components in the mechanism. When the object needs to be lifted, the rotation of the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com