Nonpolar macroporous adsorption resin carboxylation modification method for glycyrrhizic acid adsorption

A technology of non-polar macroporous and adsorbent resins, which is applied in the field of carboxylation modification of non-polar macroporous adsorbent resins, which can solve the problems of insignificant improvement of adsorbate adsorption effect, high crosslinking degree of macroporous adsorbent resins, functional low reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

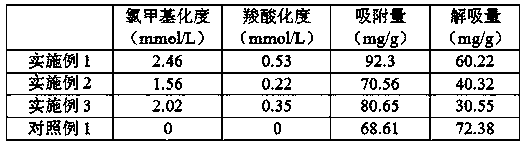

Embodiment 1

[0021] Step 1: Chloromethylation reaction

[0022] Accurately weigh 10.0 g of non-polar macroporous adsorption resin L1 that has been air-dried to constant weight and put it into a three-necked flask equipped with a stirrer and a condenser, and add 40 mL of CCl 4 After swelling at 60 °C for 30 h, the reaction device was moved into an ultrasonic reaction device. The pretreated ZnCl 2 Add 4.5 g of catalyst into the reactor, add 15 g of chloromethyl ether, and stop the reaction after reacting in an ultrasonic environment with ultrasonic power of 75 W at a temperature of 50 °C for 20 h. Transfer the macroporous adsorption resin in the reactor into the funnel of the sand core, wash with methanol and distilled water successively, repeatedly check and rinse until AgNO is added to the distilled water of the washing resin. 3 Until there is no obvious white precipitate, the chloromethylated L1 (L1-Cl) is obtained. After calculation, the degree of chloromethylation of the chloromethyl...

Embodiment 2

[0026] Step 1: Chloromethylation reaction

[0027] Precisely weigh 10 g of non-polar macroporous adsorption resin L1 that has been air-dried to constant weight and put it into a three-neck flask equipped with a stirrer and a condenser tube, add 40 mL of toluene to swell at 60 °C for 36 h, and put the reaction device Transfer to an ultrasonic reaction device. The pretreated ZnCl 2 5.0 g of catalyst was added into the reactor, 15 g of chloromethyl ether was added, and the reaction was stopped after 20 h of reaction in an ultrasonic environment with an ultrasonic power of 100 W at a temperature of 50 °C. Transfer the macroporous adsorption resin in the reactor into the funnel of the sand core, wash with methanol and distilled water successively, repeatedly check and rinse until AgNO is added to the distilled water of the washing resin. 3 Until there is no obvious white precipitate, the chloromethylated L1 (L1-Cl) is obtained. After calculation, the degree of chloromethylation ...

Embodiment 3

[0031] Step 1: Chloromethylation reaction

[0032] Accurately weigh 10 g of non-polar macroporous adsorption resin L1 that has been air-dried to constant weight and put it into a three-necked flask equipped with a stirrer and a condenser, and add a mixture of carbon tetrachloride and chloroform ( V CCl4 : V CHCl3 = 1:1) as a solvent, after swelling at 60 °C for 48 h, the reaction device was moved into an ultrasonic reaction device. The pretreated ZnCl 2 5.0 g of catalyst was added into the reactor, 20 g of chloromethyl ether was added, and the reaction was stopped after 36 h of reaction in an ultrasonic environment with an ultrasonic power of 75 W at a temperature of 50 °C. Transfer the macroporous adsorption resin in the reactor into the funnel of the sand core, wash with methanol and distilled water successively, repeatedly check and rinse until AgNO is added to the distilled water of the washing resin. 3Until there is no obvious white precipitate, the chloromethylat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com