Patents

Literature

60results about How to "Reduce desorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

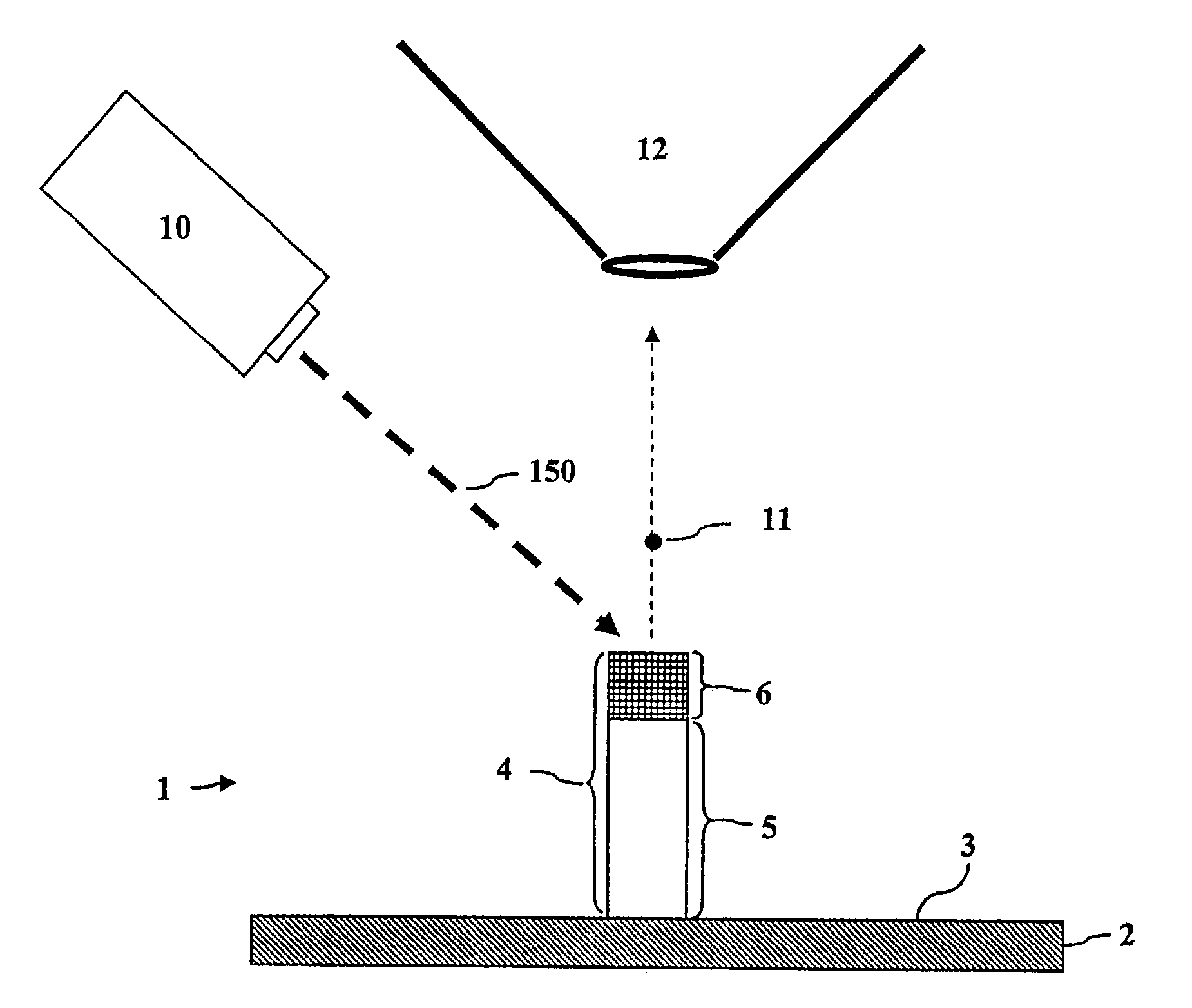

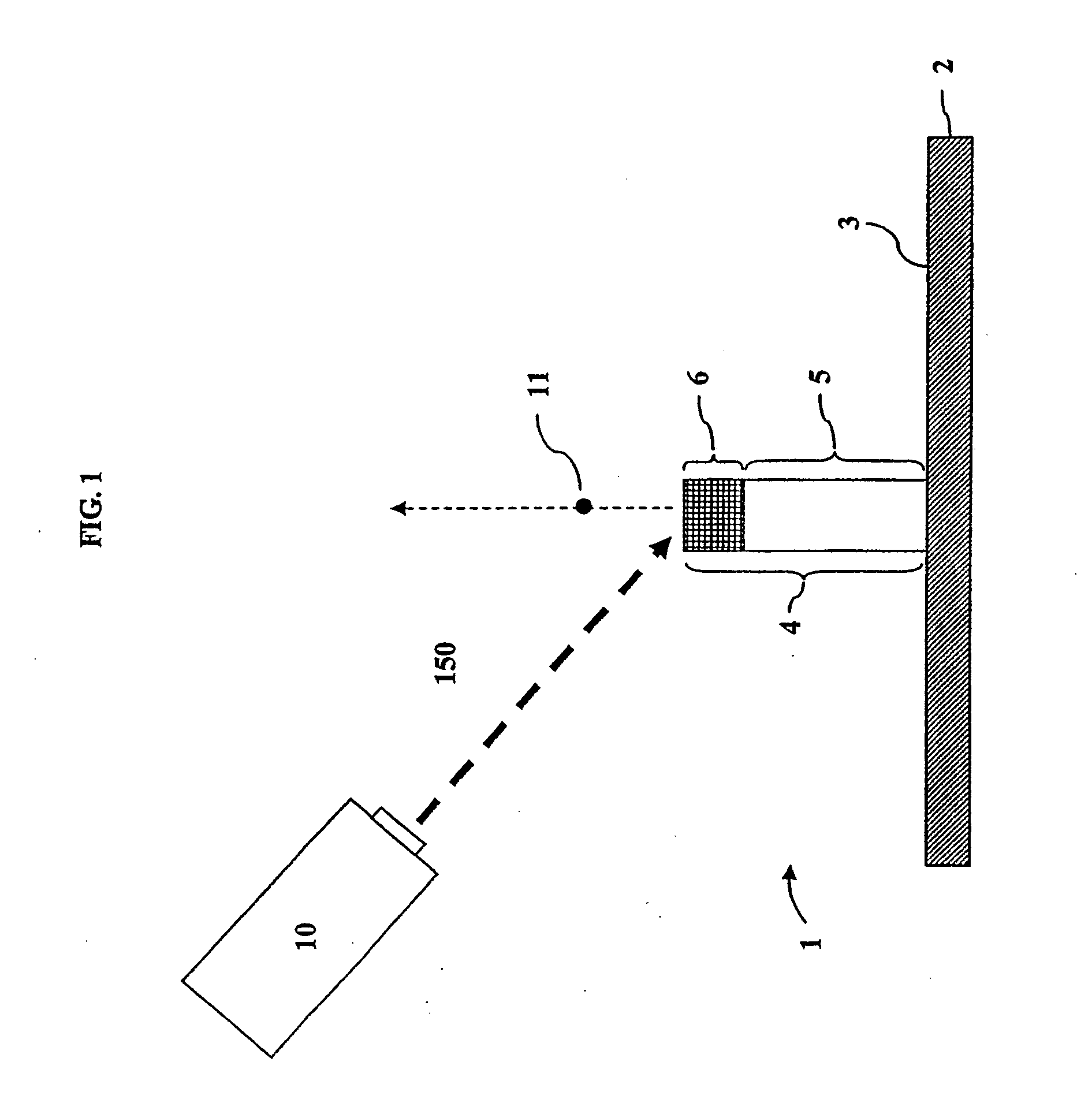

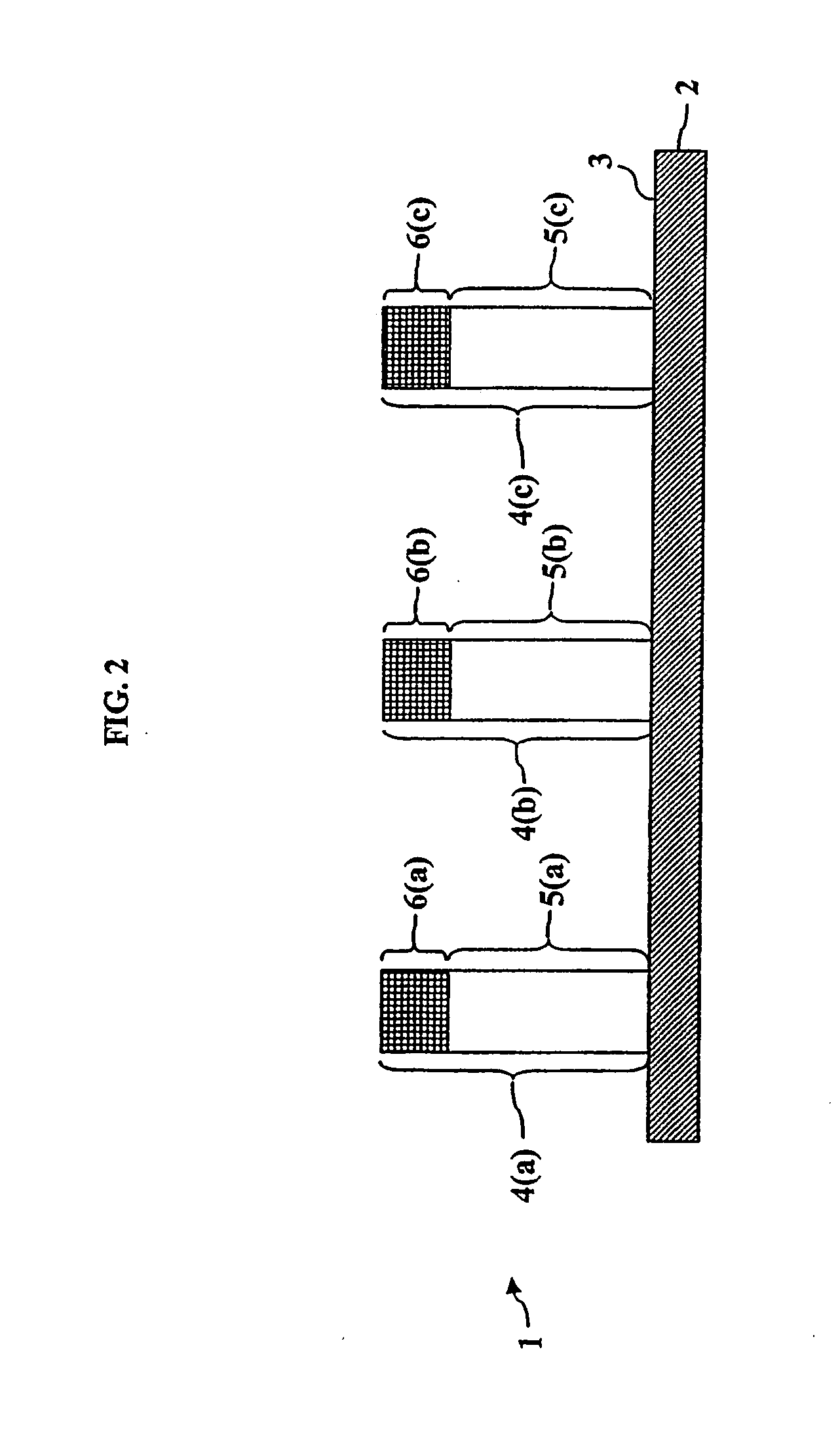

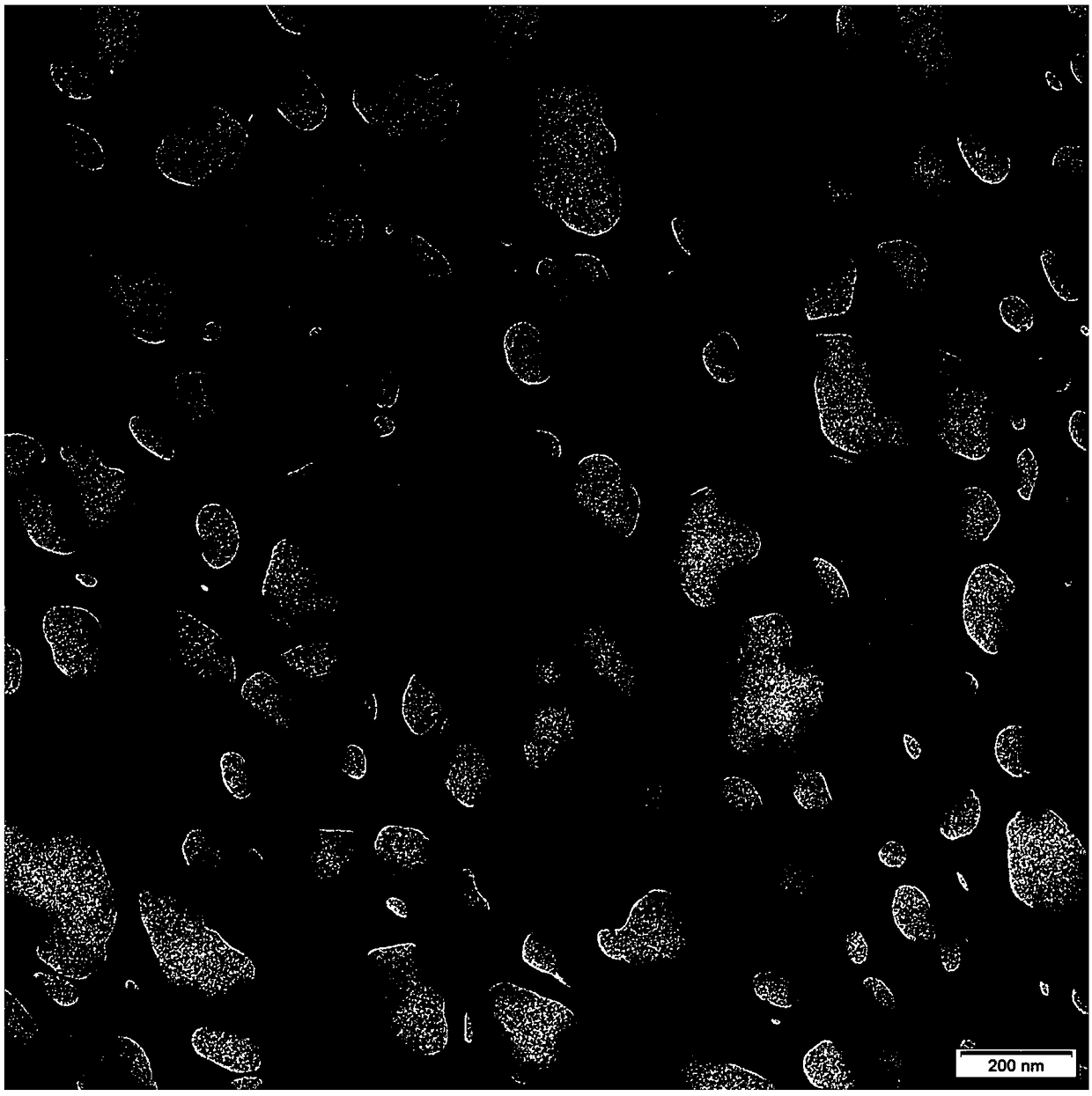

Ion detection using a pillar chip

InactiveUS20080203291A1Reduce desorptionIncreased ionizationSludge treatmentParticle separator tubesElectric potentialIon

Methods and assemblies for ion detection in samples using a chip with elevated sample zones, also known as a “pillar chip.” Methods include analyzing such a sample by desorbing a sample from a chip, producing a described ion sample and detecting the same. The chip comprises a base having a surface and one or more structures protruding above the surface of the base. Each structure comprises a pillar and a sample zone, the latter containing a support material and the sample to be analyzed. Assemblies include a chip such as that described above and a conductive element that comprises an aperture of sufficient proportion to allow passage of a molecular ion and that is adapted to be at a different electrical potential than the base of the chip.

Owner:ZYOMYX

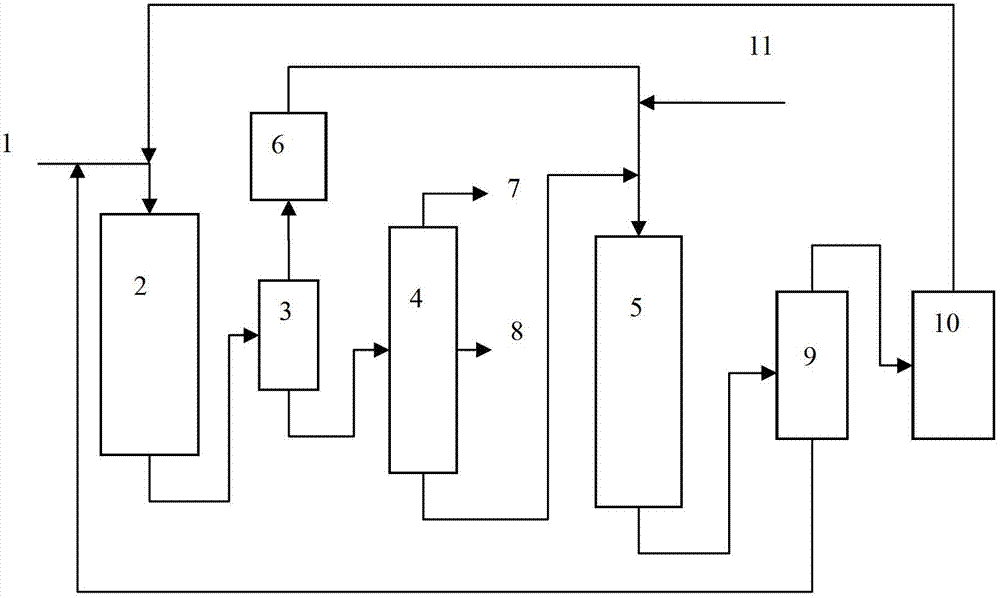

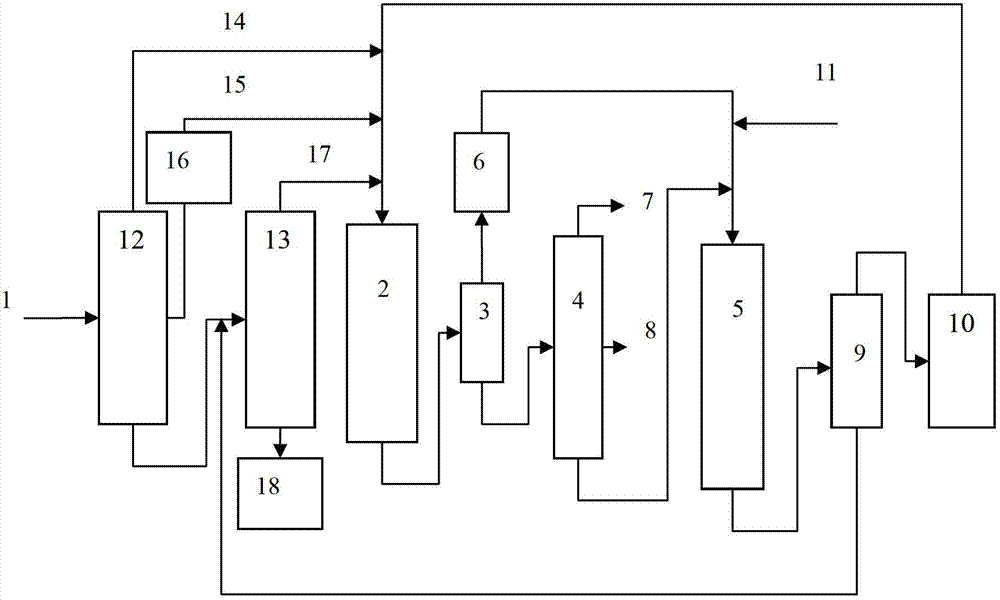

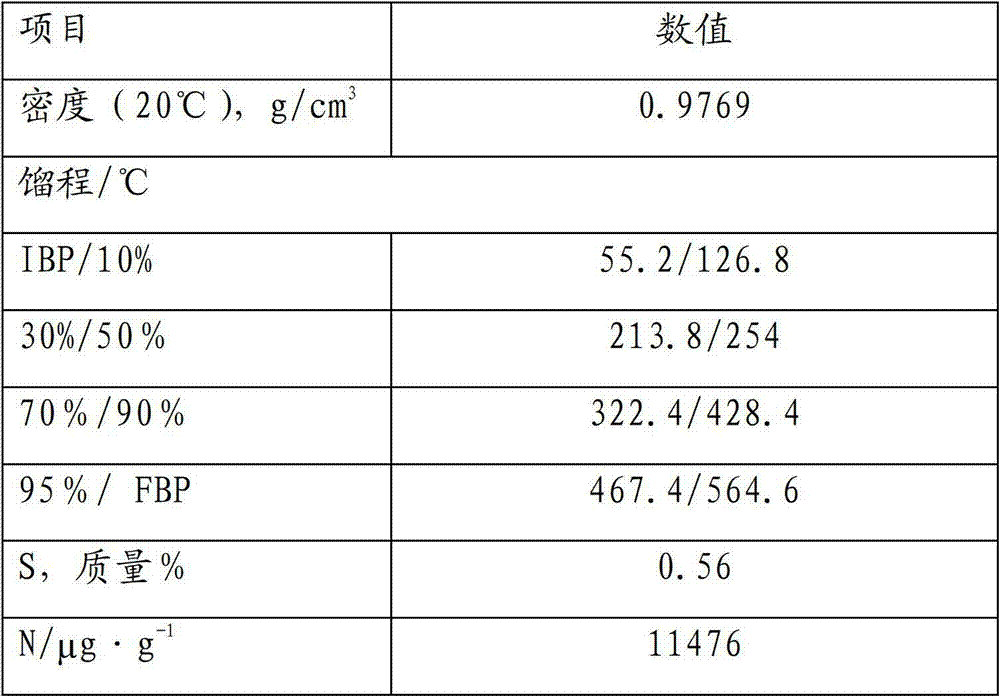

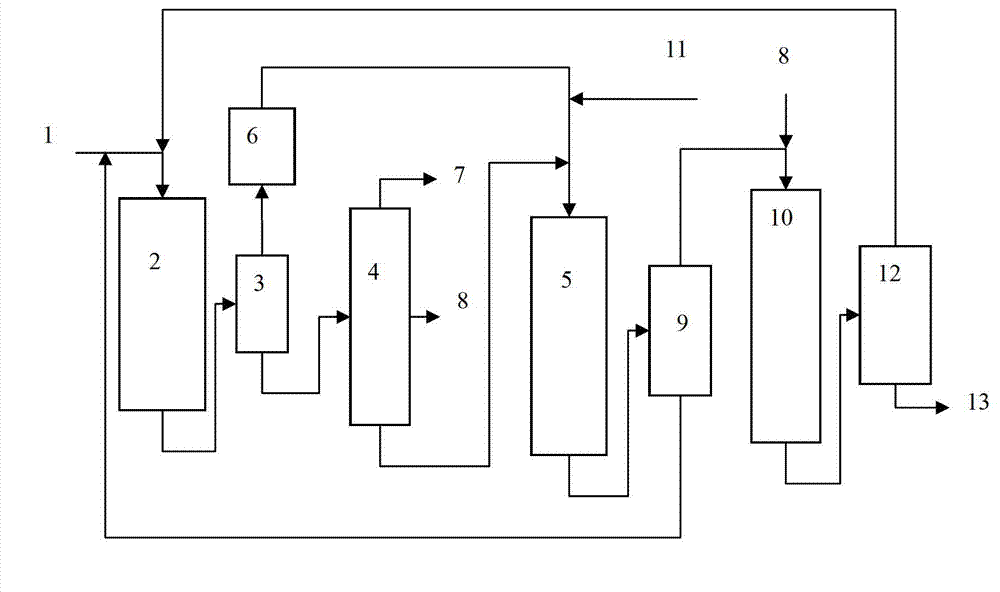

Two-stage hydrogenation process of coal tar

ActiveCN102851071AHigh yieldOvercome expensiveTreatment with hydrotreatment processesPtru catalystThermodynamics

The invention discloses a two-stage hydrogenation process of coal tar. The process comprises the steps of: (a) sending a coal tar raw material into a hydrotreating reaction section, and carrying out a hydrotreating reaction on the coal tar by contacting with a hydrotreating catalyst in the presence of hydrogen and under hydrogenation conditions; (b) carrying out gas-liquid separation on an effluent from the hydrogenating reaction section, and sending a separated liquid phase into the a fractionation device, in order to distillate out a light fraction and a heavy fraction; (c) sending at least part of the heavy fraction from the step (b) into a hydrocracking reaction section, and carrying out a hydrocracking reaction on the heavy fraction by contacting with a hydrocracking catalyst in the presence of hydrogen and under hydrogenation cracking conditions; and (d) sending an effluent from the hydrocracking reaction section into a hot high pressure separator, in order to separate out a gas phase and a liquid phase, and sending at least part of the liquid phase to the hydrotreating reaction section in the step (a). Compared with the prior art, the method provided by the invention improves the yield of light fuel production from coal tar, prolongs the service life of a catalyst, and increases operation cycle of the device.

Owner:上海竣铭化工工程设计有限公司

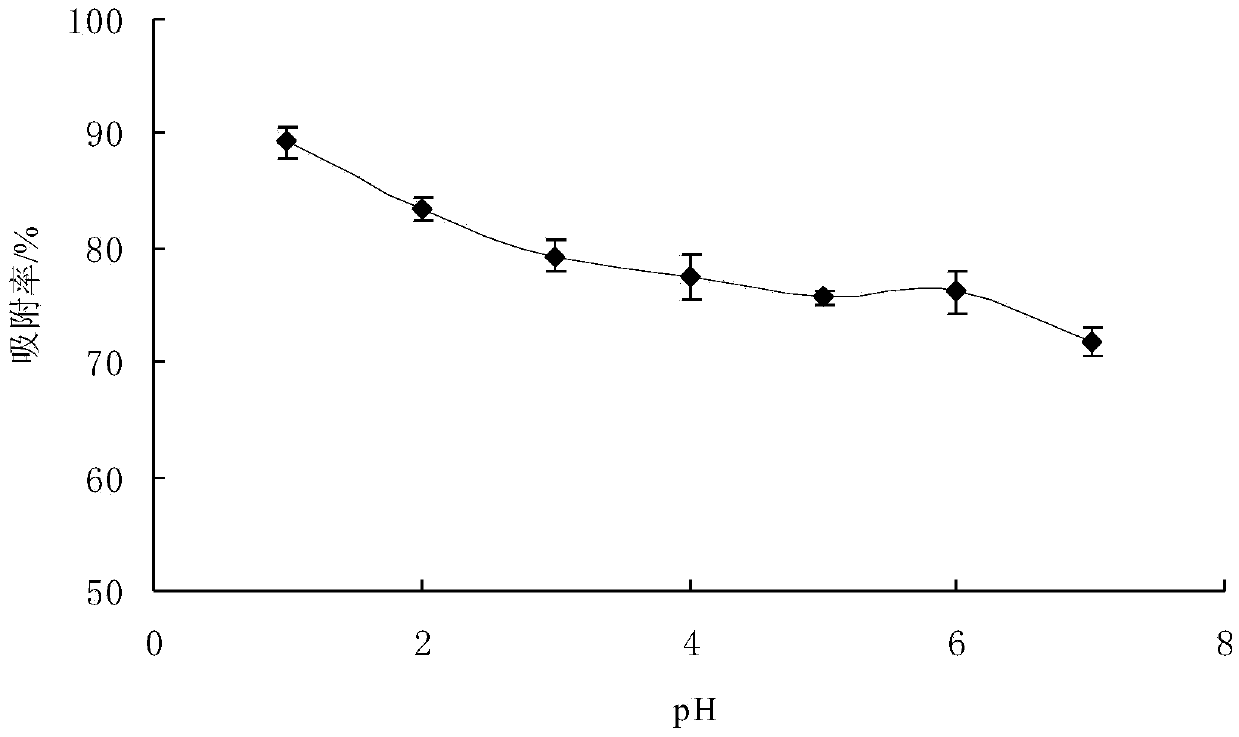

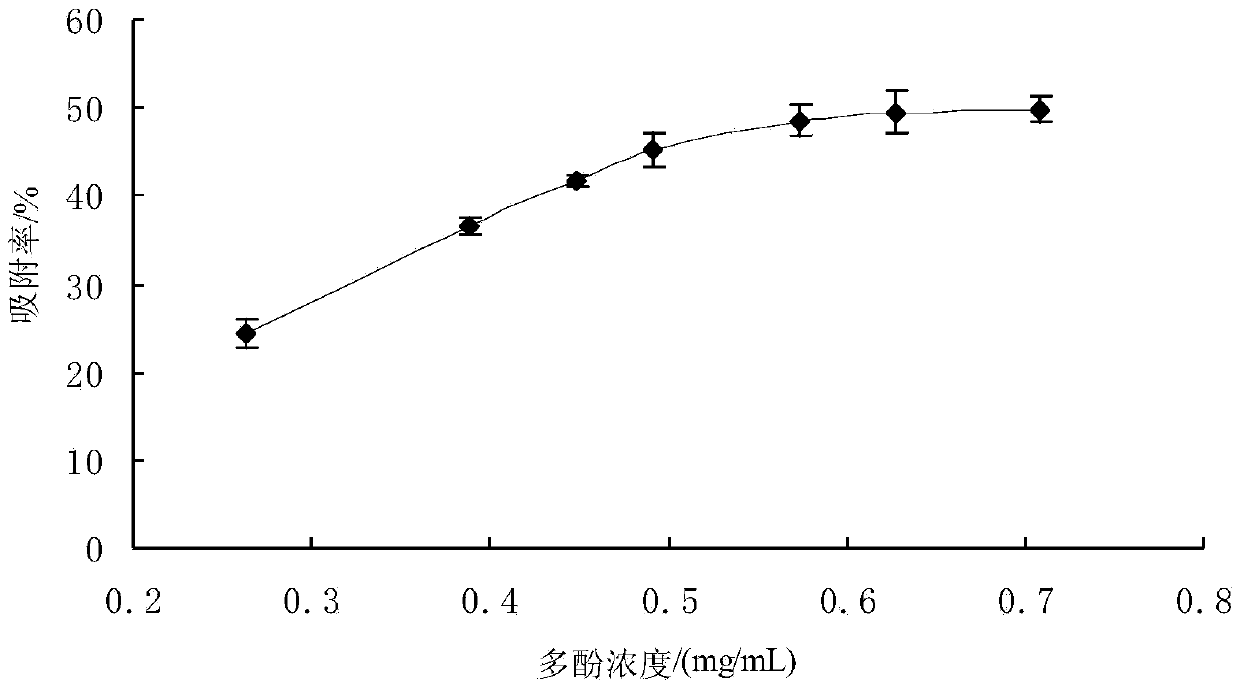

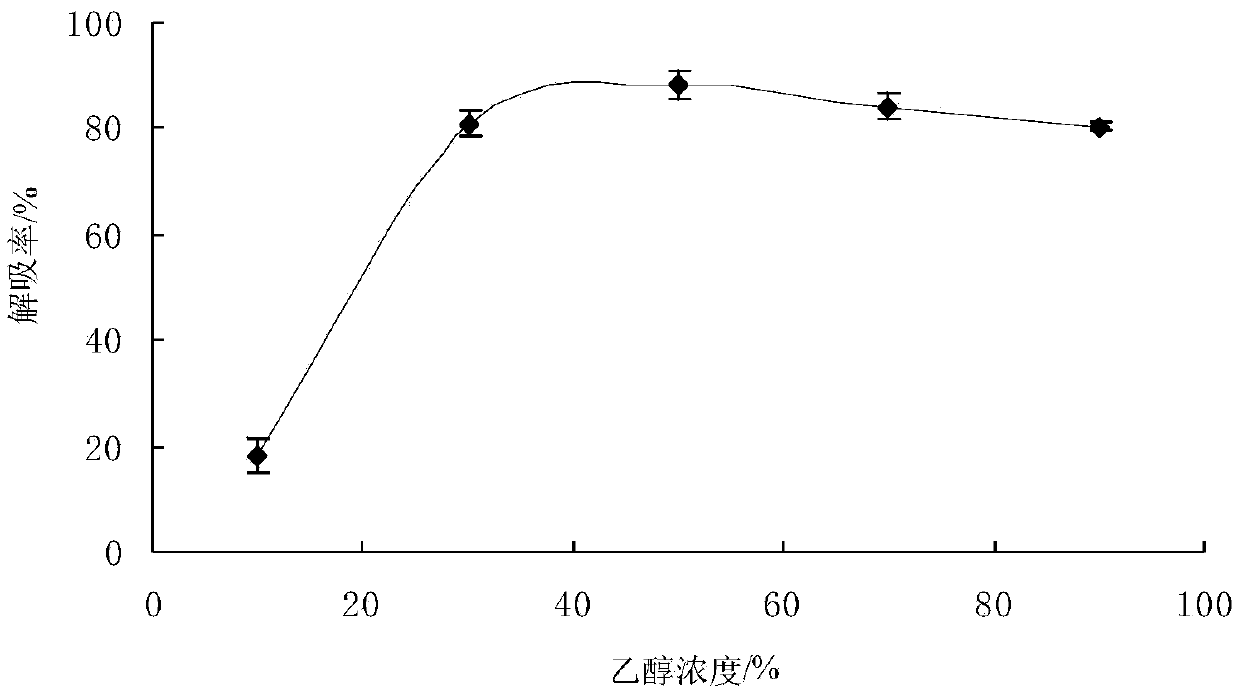

Method for separation purification of walnut green seedcase polyphenol substances by macroporous resin

The invention discloses a method for separation purification of walnut green seedcase polyphenol substances by macroporous resin. The method comprises 1, carrying out extraction on walnut green seedcase dry powder at a temperature of 35-40 DEG C through ethanol with content of 50% under ultrasonic action many times, carrying out vacuum filtration on the extract, evaporating the filtrate to obtain walnut green seedcase polyphenol crude extract, diluting the walnut green seedcase polyphenol crude extract until a desired concentration is obtained, and carrying out refrigeration for next use, 2, determining total polyphenol content of walnut green seedcase by a Folin-Ciocaileu method, 3, carrying out macroporous resin pretreatment, 4, carrying out macroporous resin static adsorption and desorption, 5, carrying out macroporous resin dynamic adsorption and desorption, and 6, through a HPLC method, determining free phenol content and composition of the walnut green seedcase polyphenol extract obtained by the macroporous resin separation purification so that the whole separation purification process is finished. The method provides the novel approach for separation purification of walnut green seedcase polyphenol substances, can be operated simply and realizes high separation purification quality and efficiency.

Owner:HENGSHAN COUNTY HONGMENGYUAN TECH IND CO LTD

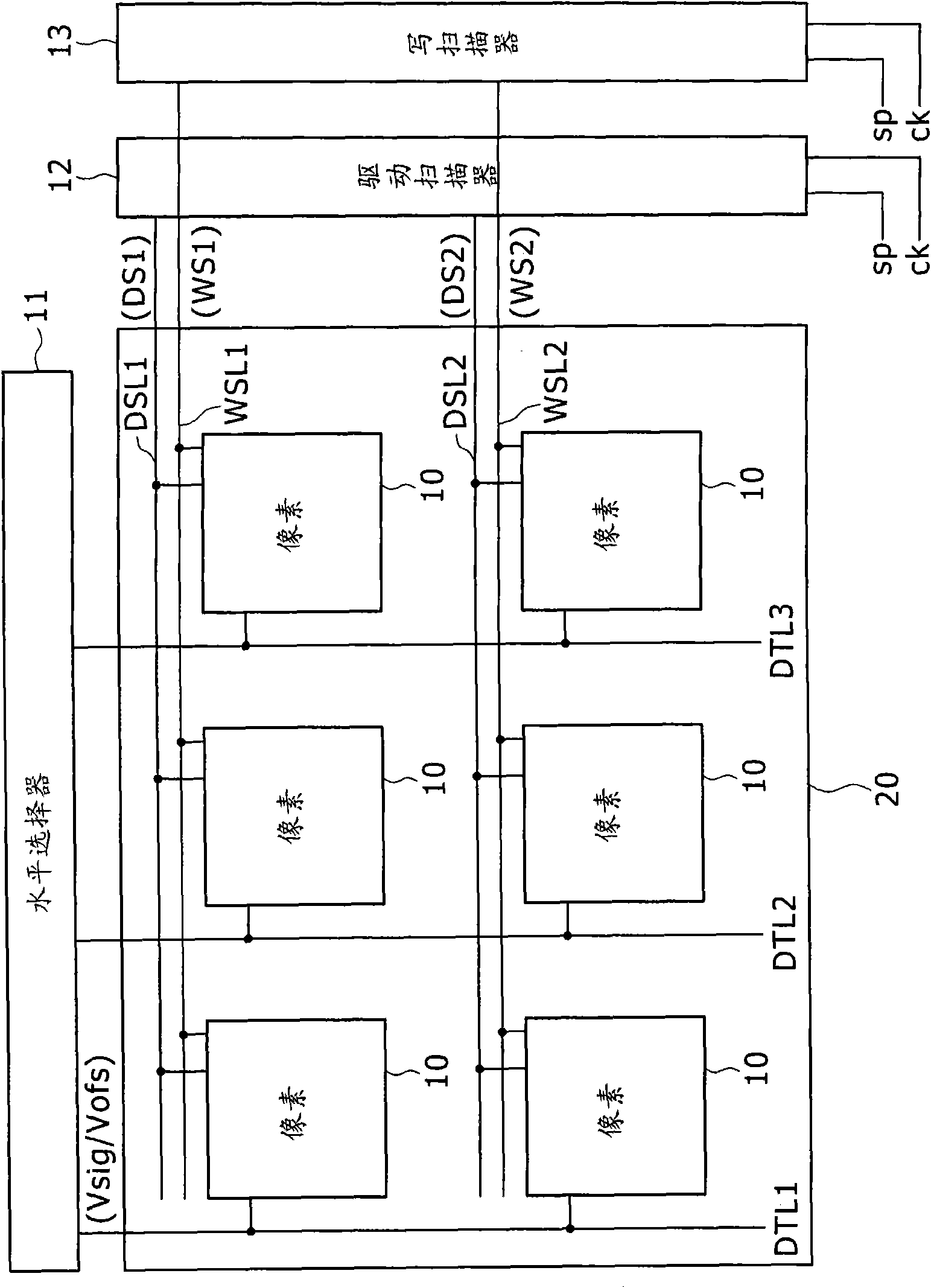

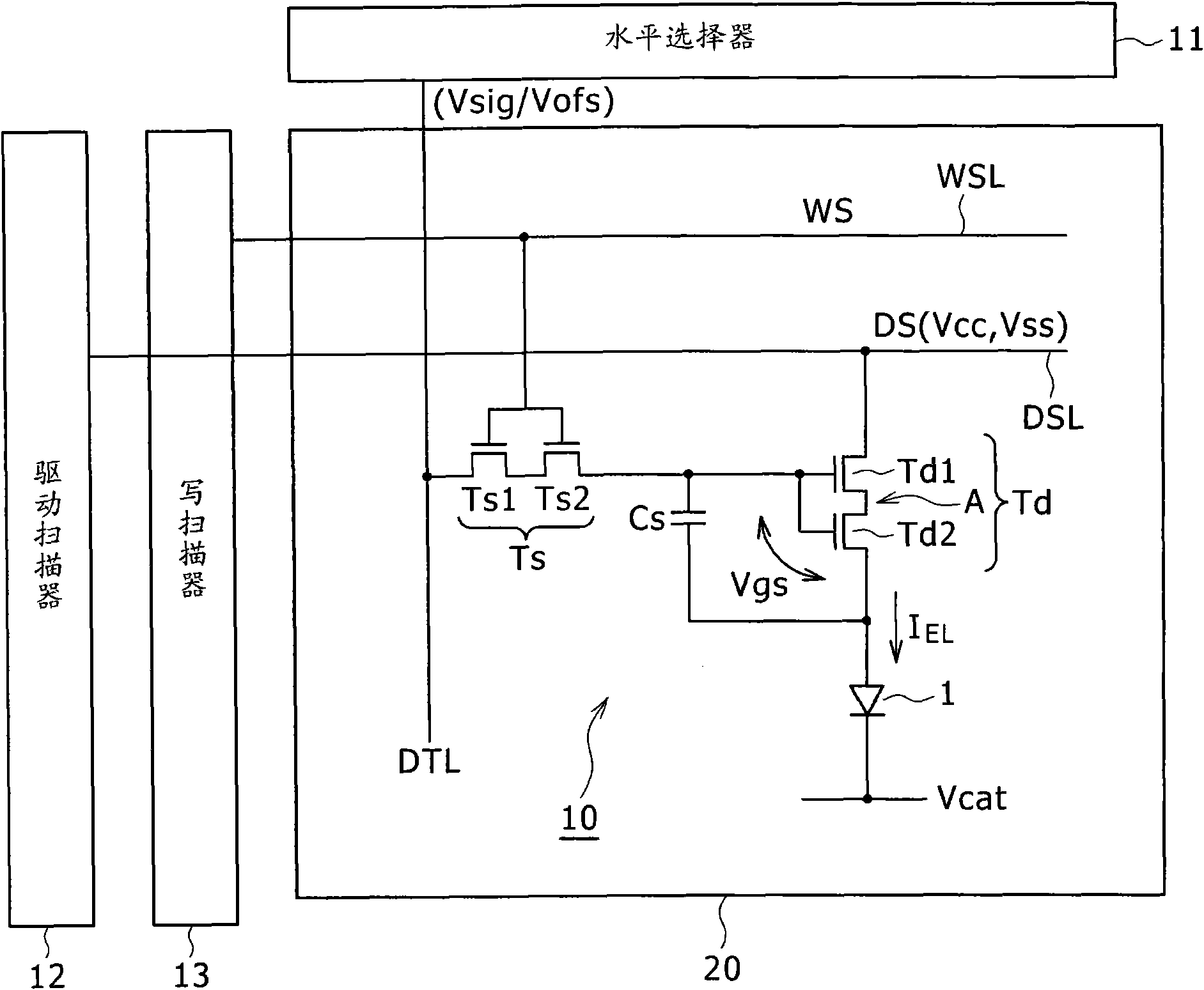

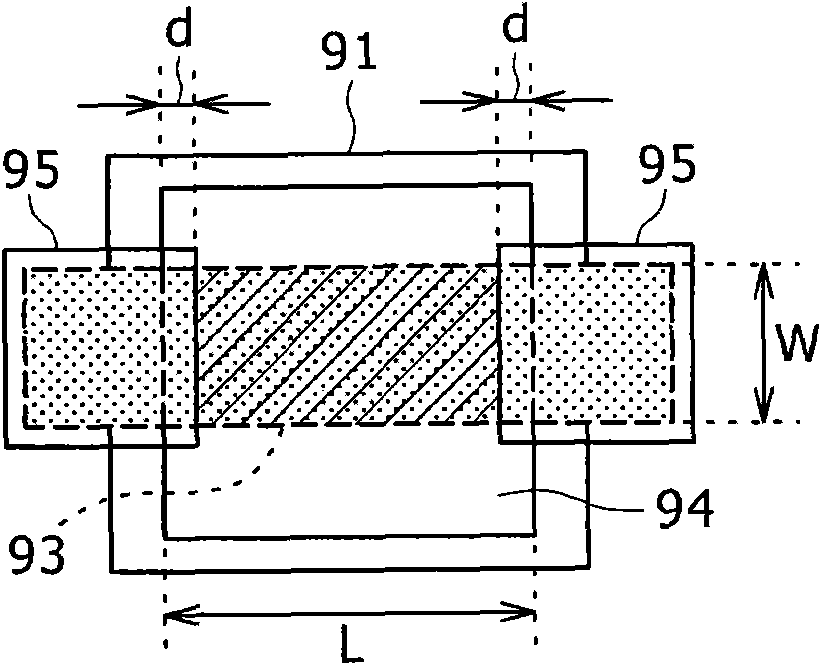

Display apparatus

ActiveCN101887684AEliminate inappropriate operationsSolution to short lifeStatic indicating devicesSolid-state devicesSemiconductor materialsEngineering

A display apparatus includes: a pixel array including a plurality of pixel circuits disposed in a matrix and each including a light emitting element, a driving transistor for supplying current in response to a signal value applied between a gate and a source thereof to the light emitting element when a driving voltage is applied between a drain and the source thereof, and a holding capacitor connected between the gate and the source of the driving transistor for holding the input signal value, the driving transistor having a multi-gate structure wherein two or more transistors formed using anoxide semiconductor material are connected in series; and a light emission driving section.

Owner:JOLED INC

Multiple-quantum well waveguide butt-coupling method

ActiveCN102545047AInterface corrosion morphology is goodPrecise control of corrosion depthOptical wave guidanceLaser active region structureCoupling lossEtching

The invention relates to a multiple-quantum well waveguide butt-coupling method comprising the following steps of: A, carrying out primary epitaxy on a substrate to obtain a multiple-quantum well structure; B, after a dielectric film is deposited, carrying out mask photoetching, and removing a waveguide part of a first region requiring secondary epitaxy by using a three-step etching method; C, placing an epitaxial wafer into metal organic chemical vapor deposition equipment for high-temperature treatment; and D, carrying out secondary epitaxial growth to obtain a second multiple-quantum well structure. By using the method, an attractive interface etching appearance can be achieved, cavities caused during growth can be avoided, the butting quality can be effectively improved, the coupling loss can be reduced, and good repeatability can be obtained. The multiple-quantum well waveguide butt-coupling method can be used for manufacture and batch production of various photoelectronic integrated chips.

Owner:WUHAN HUAGONG GENUINE OPTICS TECH

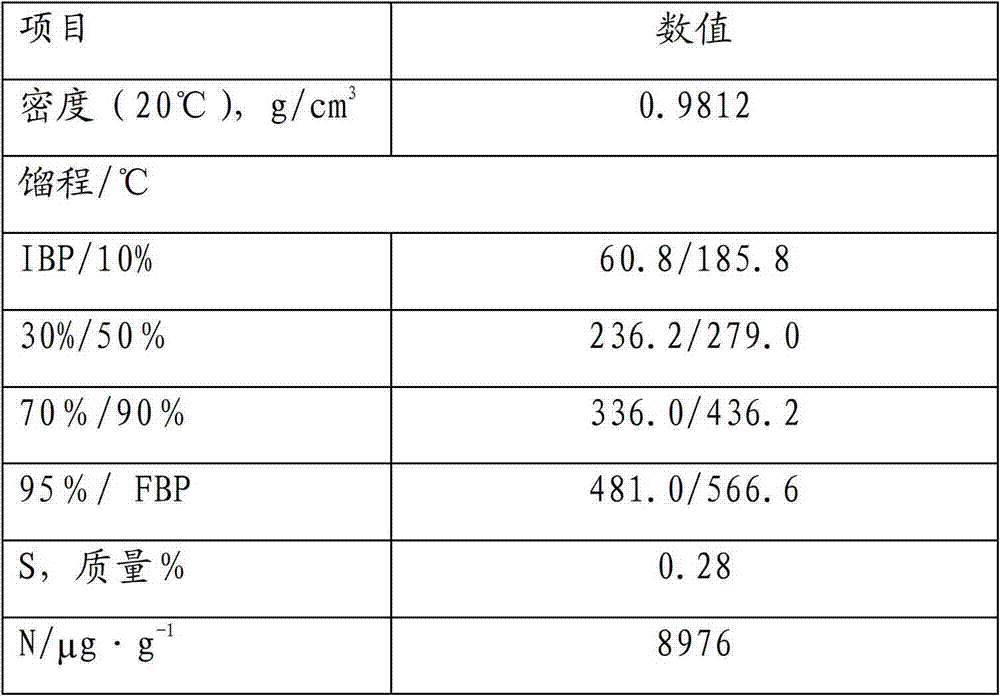

Medium and low temperature combination processing method of coal tar

ActiveCN102851073AHigh yieldLow yieldTreatment with hydrotreatment processesTar working-up by distillationLighter fuelHigh pressure

The invention comprises a combination processing method of coal tar. The method comprises the steps of: (a) subjecting a coal tar raw material to atmospheric distillation to obtain light distillate oil, phenol oil and bottom oil; dephenolizing the phenol oil to obtain the dephenolized oil; sending the bottom oil and a liquid phase from a hot high pressure separator in a step (d) into a vacuum distillation tower to obtain a heavy distillate with asphaltene removed; and conducting a hydrotreating reaction on the light distillate, dephenolized oil and the heavy distillate; (b) fractionating a liquid phase from the hydrotreating reaction into a light fraction and a heavy fraction; (c) subjecting the heavy fraction from the step (b) to a hydrocracking reaction; and (d) sending an effluent from the hydrocracking reaction into the hot high pressure separator, and sending the separated liquid phase to the vacuum distillation tower in the step (a). Compared with prior art, the method provided by the invention increases yield of light fuel production from coal tar, prolongs the service life of catalyst, and improves operation cycle of the device.

Owner:吉林省弘泰新能源有限公司

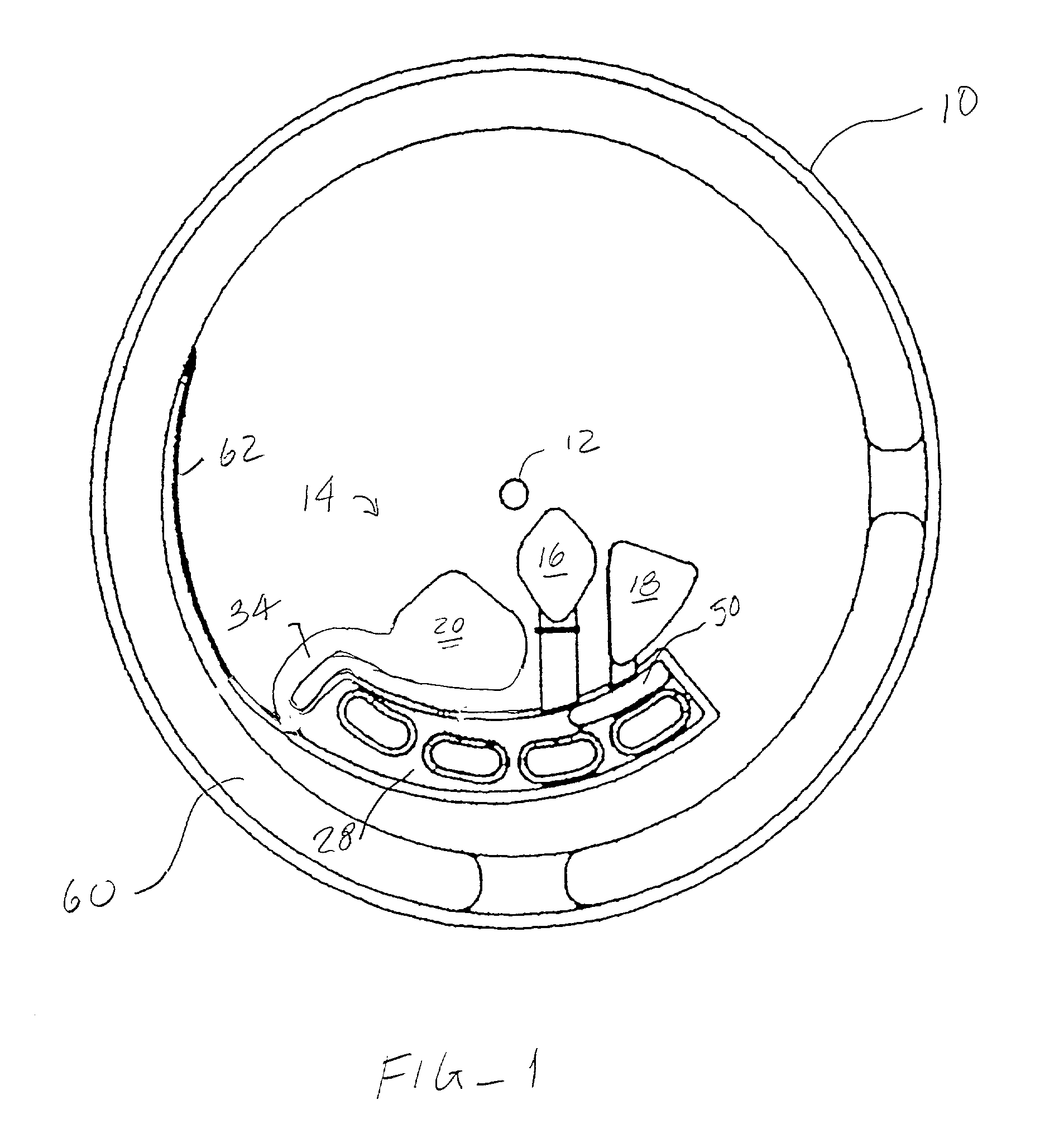

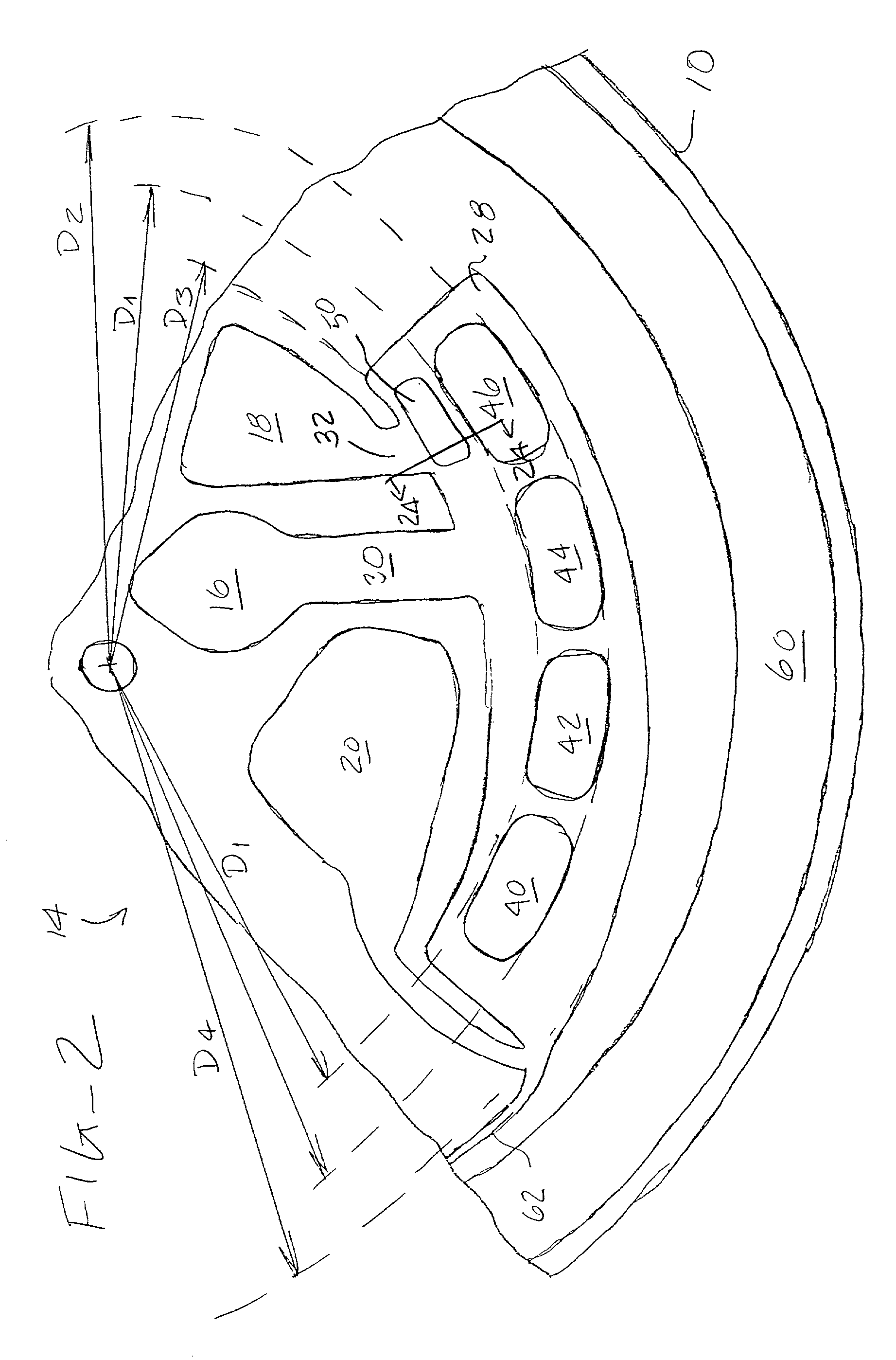

Analytical rotor and method for detecting analytes in liquid samples

InactiveUS20020025583A1Increase flow resistanceIncrease the cross-sectional areaMaterial analysis by optical meansAnalyteLow speed

An analytical rotor intended primarily for performing immunoassays comprises one or more inlet chambers for sample, wash reagents, and labelling reagents. A reaction chamber is disposed radially outwardly from the inlet chambers and connected thereto by low flow resistance flow paths. A collection chamber is located radially outwardly from the reaction chamber and connected thereto by a high flow resistance flow path. Samples are introduced to the sample inlet chamber by a transfer device, with sample volumes optionally determined by detecting when the sample inlet chamber is filled. Reagents initially introduced to the inlet chambers may be selectively transferred to the reaction chamber by low speed rotation of the rotor. The reaction chamber may then be emptied by high speed rotation of the rotor. In this way, heterogeneous immunoassays requiring sequential contact of reaction zones with sample and different reagents may be performed.

Owner:FIRST MEDICAL

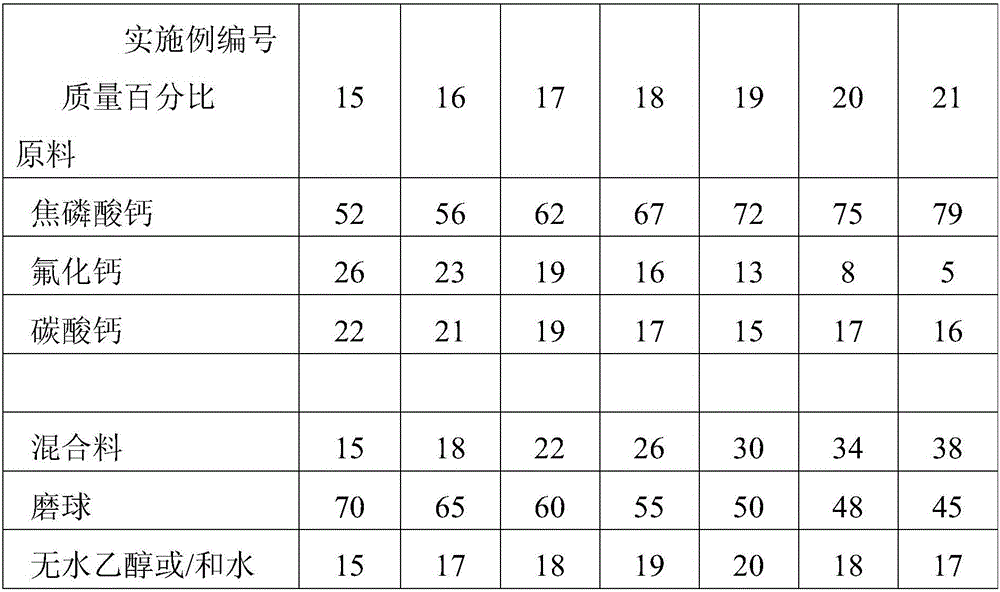

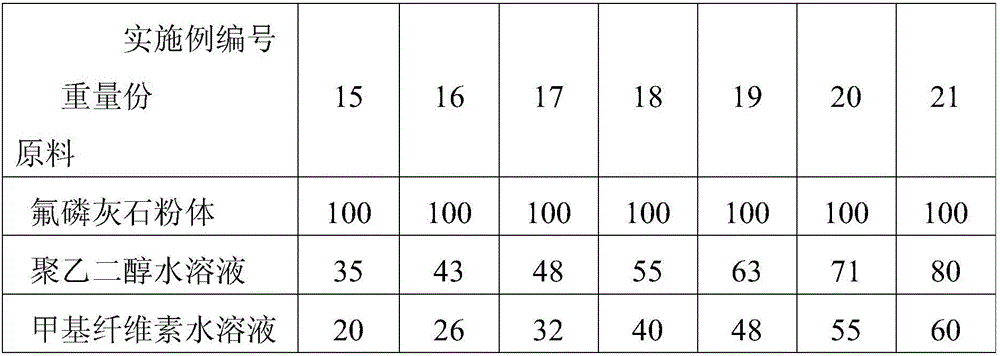

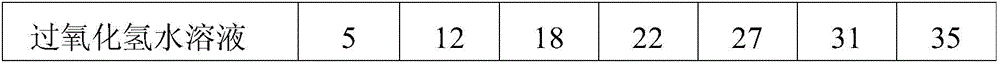

Method for preparing porous fluorapatite ceramic adsorbing radioactive nuclide

ActiveCN106045495AGood chemical stabilityReduce solubilityRadioactive decontaminationCeramicwareEcological environmentPolyethylene glycol

A method for preparing porous fluorapatite ceramic adsorbing radioactive nuclide is characterized by including: using the materials in percent by weight: 50-80% of calcium pyrophosphate, 4-26% of calcium fluoride and 16-45% of calcium carbonate, and mixing, ball-milling, drying, press-forming, calcining, grinding, and screening to obtain fluorapatite powder; mixing the fluorapatite powder with polyethylene glycol solution, methyl cellulose solution and hydrogen peroxide solution, and performing microwave assisted pore-forming, drying and the like to obtain a porous fluorapatite ceramic blank; preparing porous fluorapatite ceramic adsorbing material via normal pressure sintering. The porous fluorapatite ceramic adsorbing material prepared herein has the advantages of high radiation stability, good thermal stability, high mechanical and chemical stability and the like, also has high specific surface energy and nuclide adsorbing capacity and may be used as an efficient adsorbing material for radioactive nuclide in high-radioactive waste liquid, thus effectively protecting human health and ecological environment.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Nitrogen controlling material prepared based on lake sediment, preparation method and application thereof

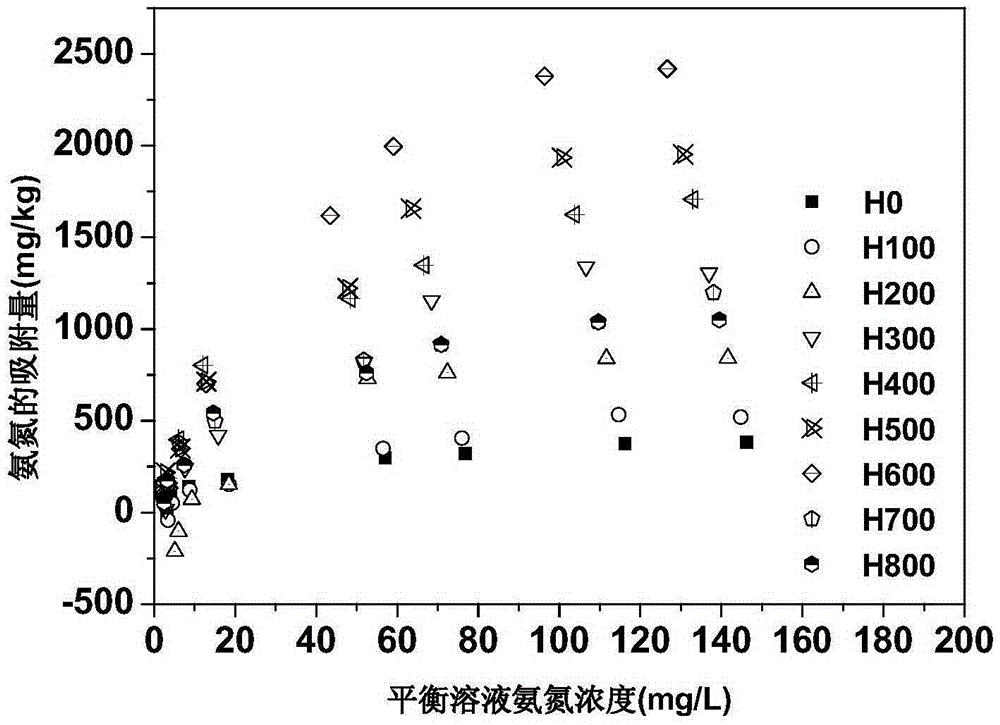

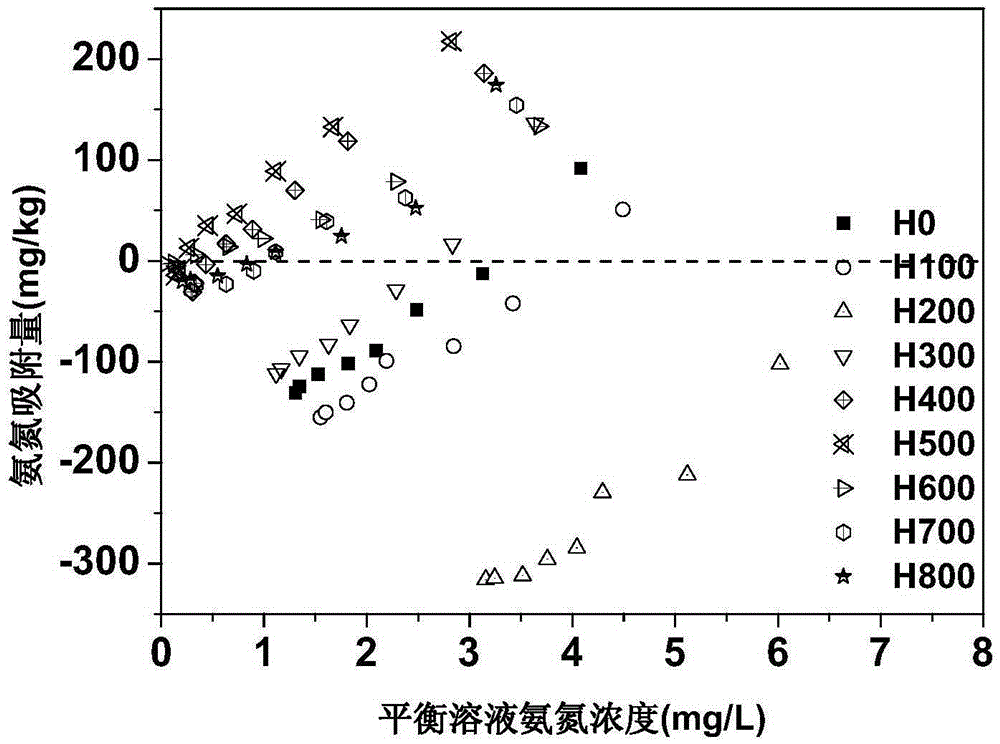

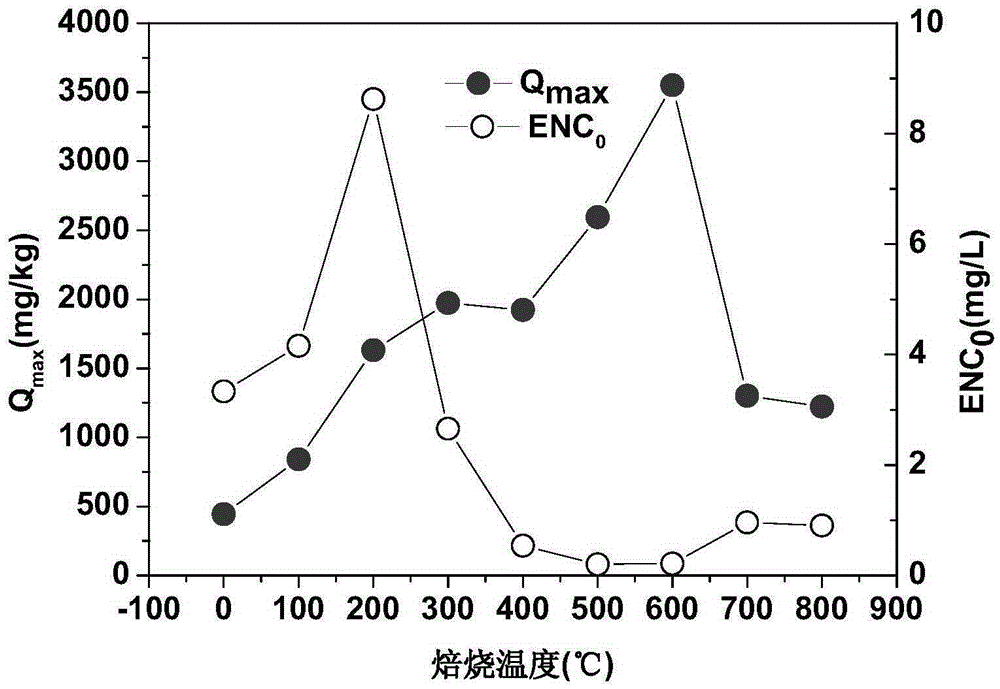

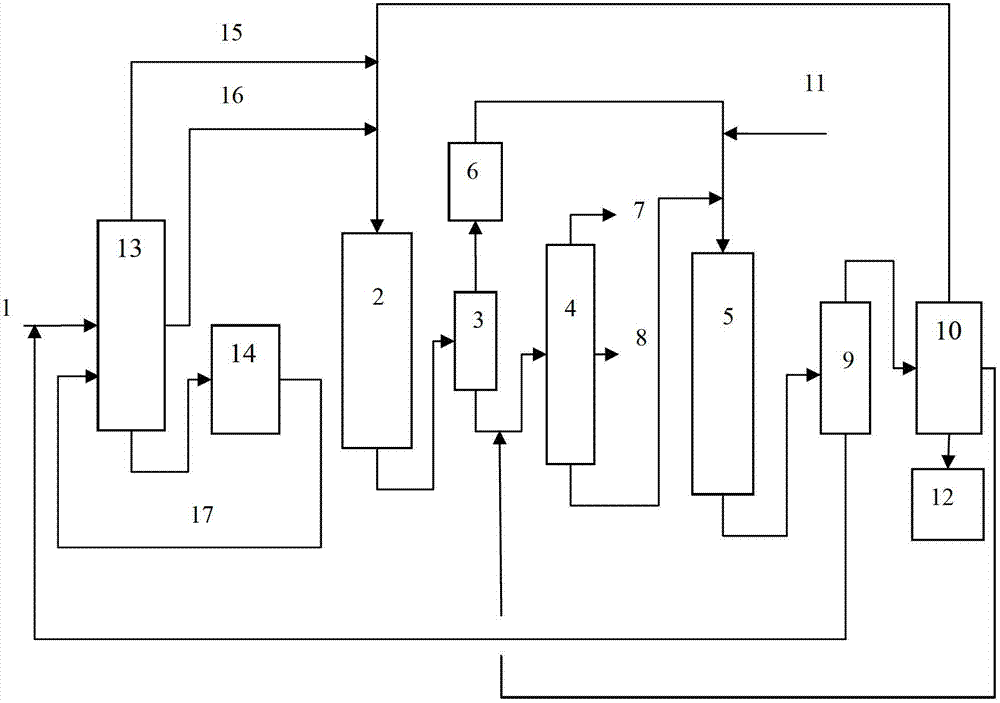

InactiveCN106000284AHigh ecological securityImprove background structureOther chemical processesSilicon compoundsAmmoniacal nitrogenSoil science

The invention relates to a nitrogen controlling material prepared based on lake sediment, a preparation method and application thereof. The preparation method includes: collecting lake sediment as the raw material, conducting freeze drying, grinding and sieving, then carrying out high temperature roasting for certain time, and performing cooling so as to obtain the nitrogen controlling material. According to the invention, lake sediment is adopted as the raw material, and is subjected to heat treatment to prepare the nitrogen controlling material. The nitrogen controlling material comes from lake sediment, not only has low price, but also has high safety, has no ecological risk to lake water, also the high temperature roasted sediment has the characteristics of strong ammonia nitrogen adsorption capacity and weak desorption, thus solving the problems of high cost of ammonia nitrogen controlled release materials, poor ecological safety and limited ammonia nitrogen controlled release effect in the prior art.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

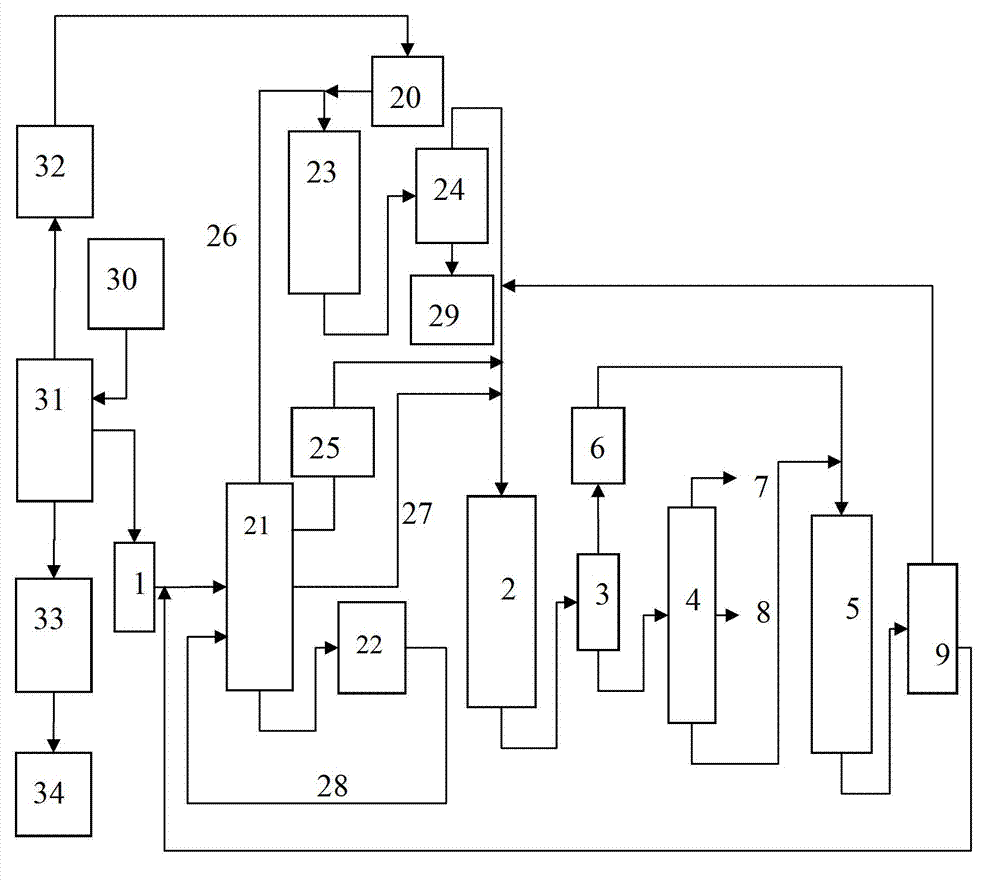

Combination processing method of coal tar

The invention comprises a combination processing method of coal tar. The method comprises the steps of: the coal tar raw material: (a) introducing a coal tar raw material, delayed coking gas oil and at least part of a liquid phase from a step (d) into a distillation tower, so as to distillate out a light distillate, wax oil and bottom oil; and subjecting the light distillate and the wax oil to a hydrotreating reaction; (b) carrying out gas-liquid separation on an effluent from the hydrotreating reaction, and sending a liquid phase into a fractionation device, so as to distillate out a light fraction and a heavy fraction; (c) carrying out a hydrocracking reaction on at least part of the heavy fraction obtained in the step (b); (d) sending an effluent from the hydrocracking reaction into a hot high pressure separator, so as to separate out a gas phase and a liquid phase; and sending at least part of the liquid phase to the distillation tower in the step (a); and (e) subjecting the bottom oil obtained from distillation in the step (a) to delayed coking, and sending the delayed coking oil gas to the distillation tower in the step (a). Compared with the prior art, the invention method improves the yield of light fuel production from coal tar, prolongs the service life of a catalyst, and increases operation cycle of the device.

Owner:上海竣铭化工工程设计有限公司

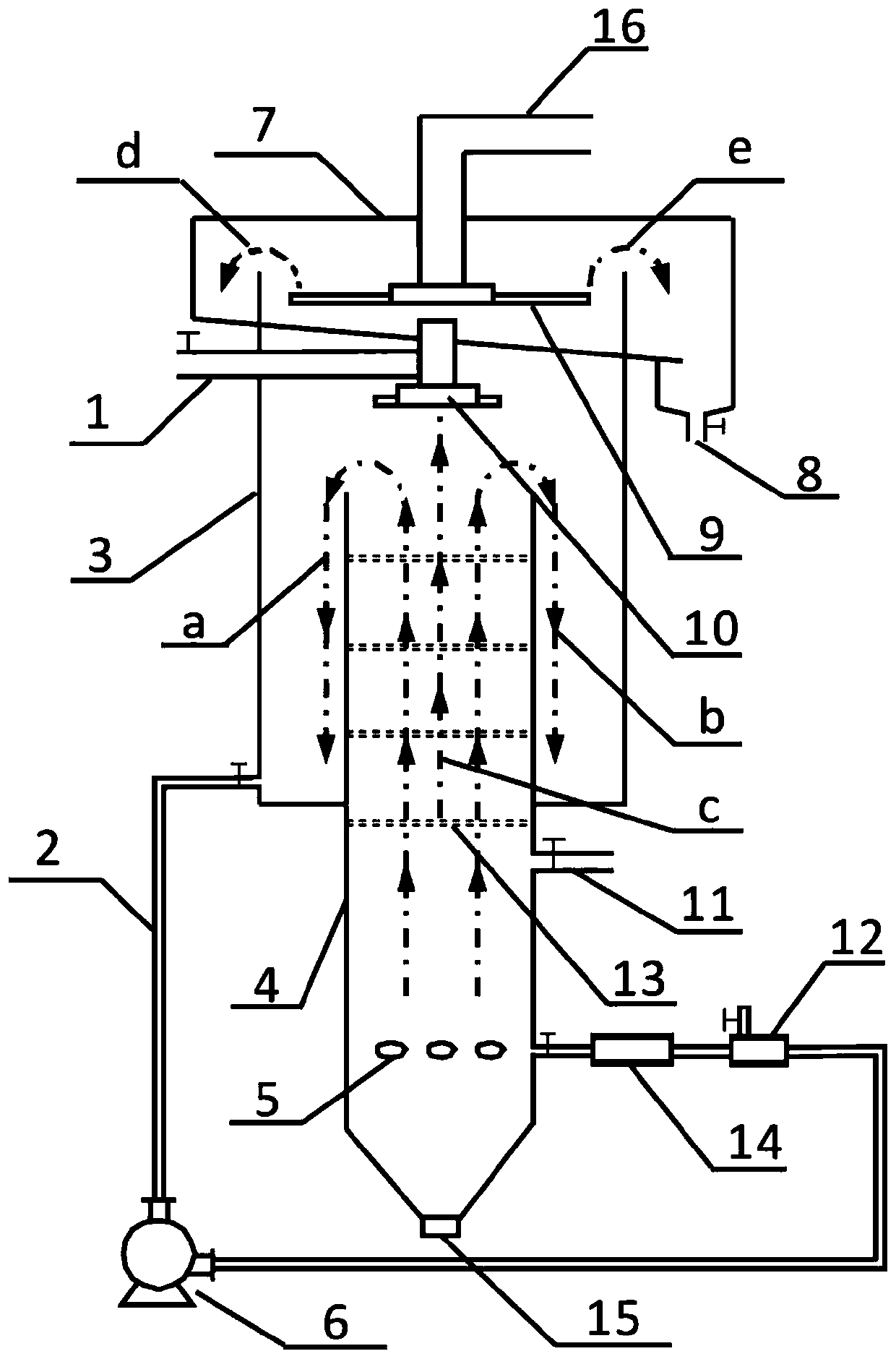

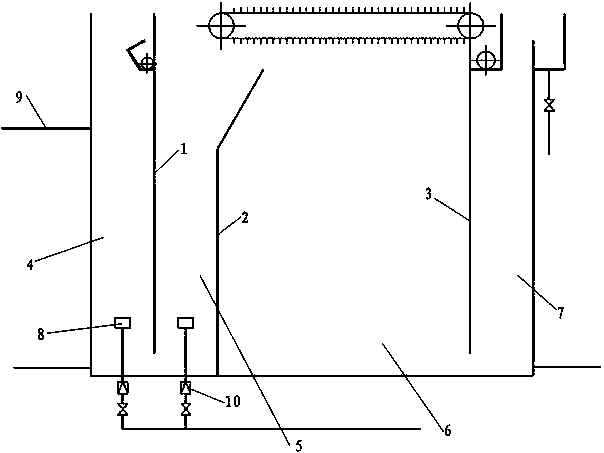

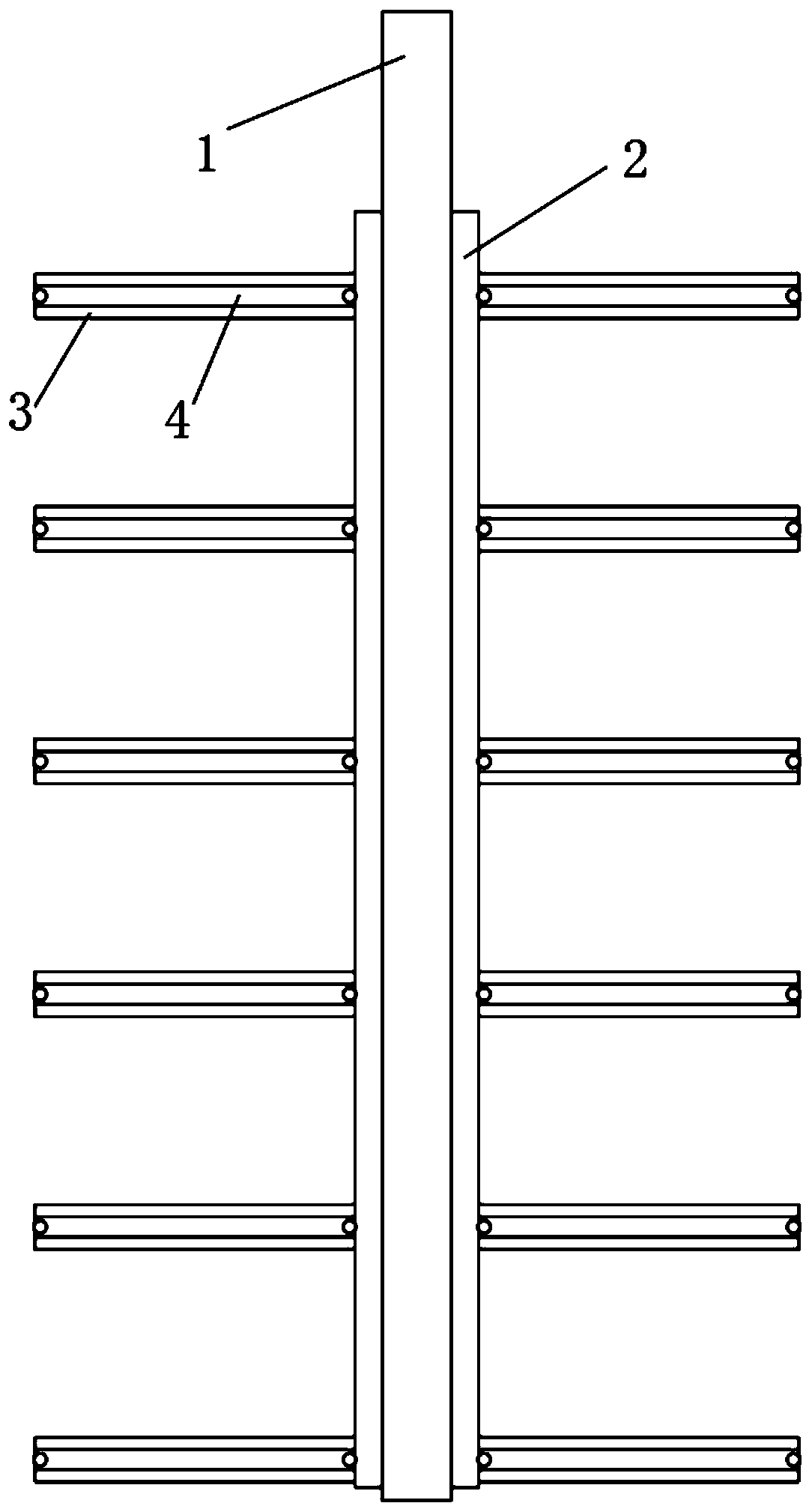

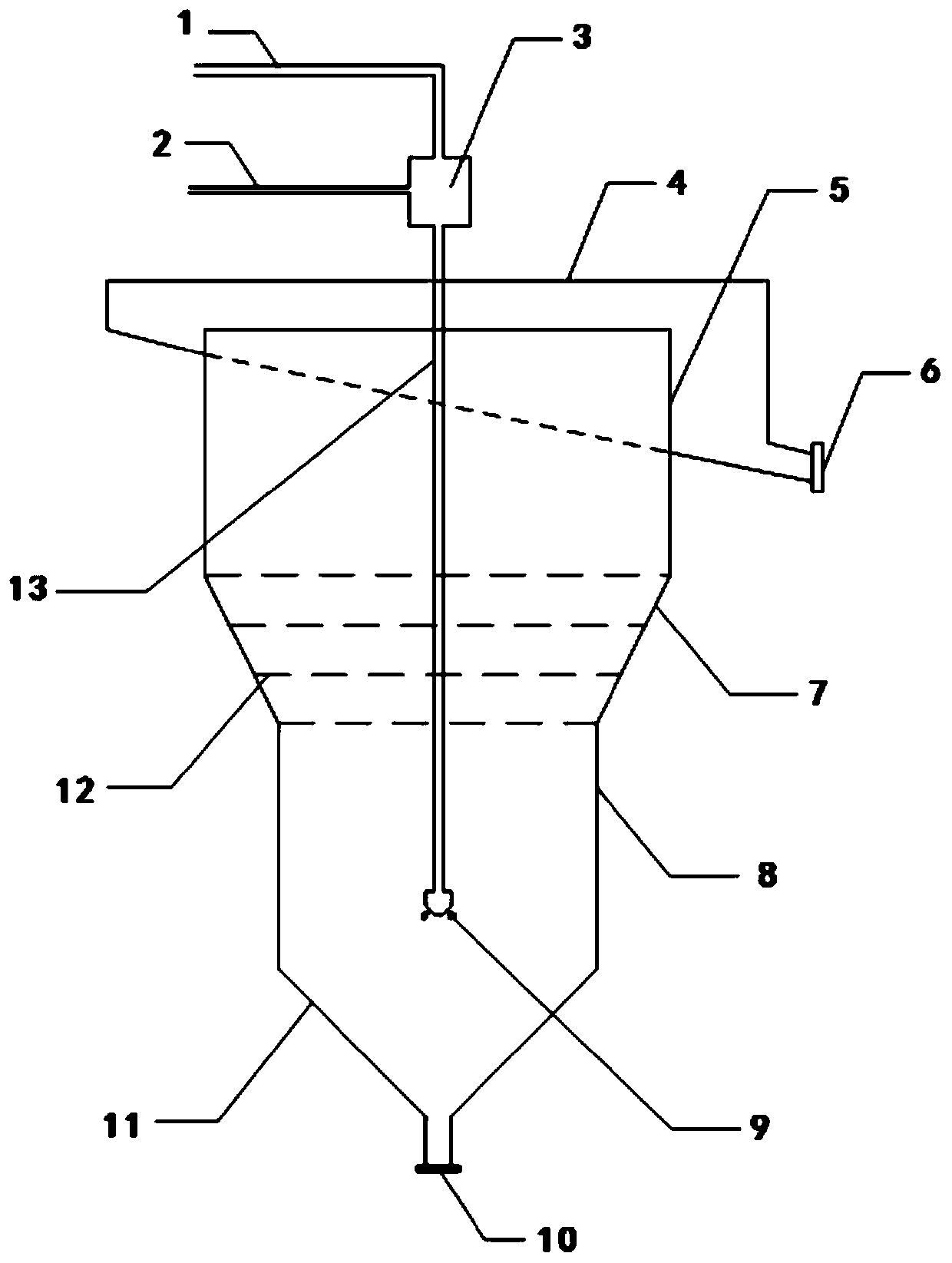

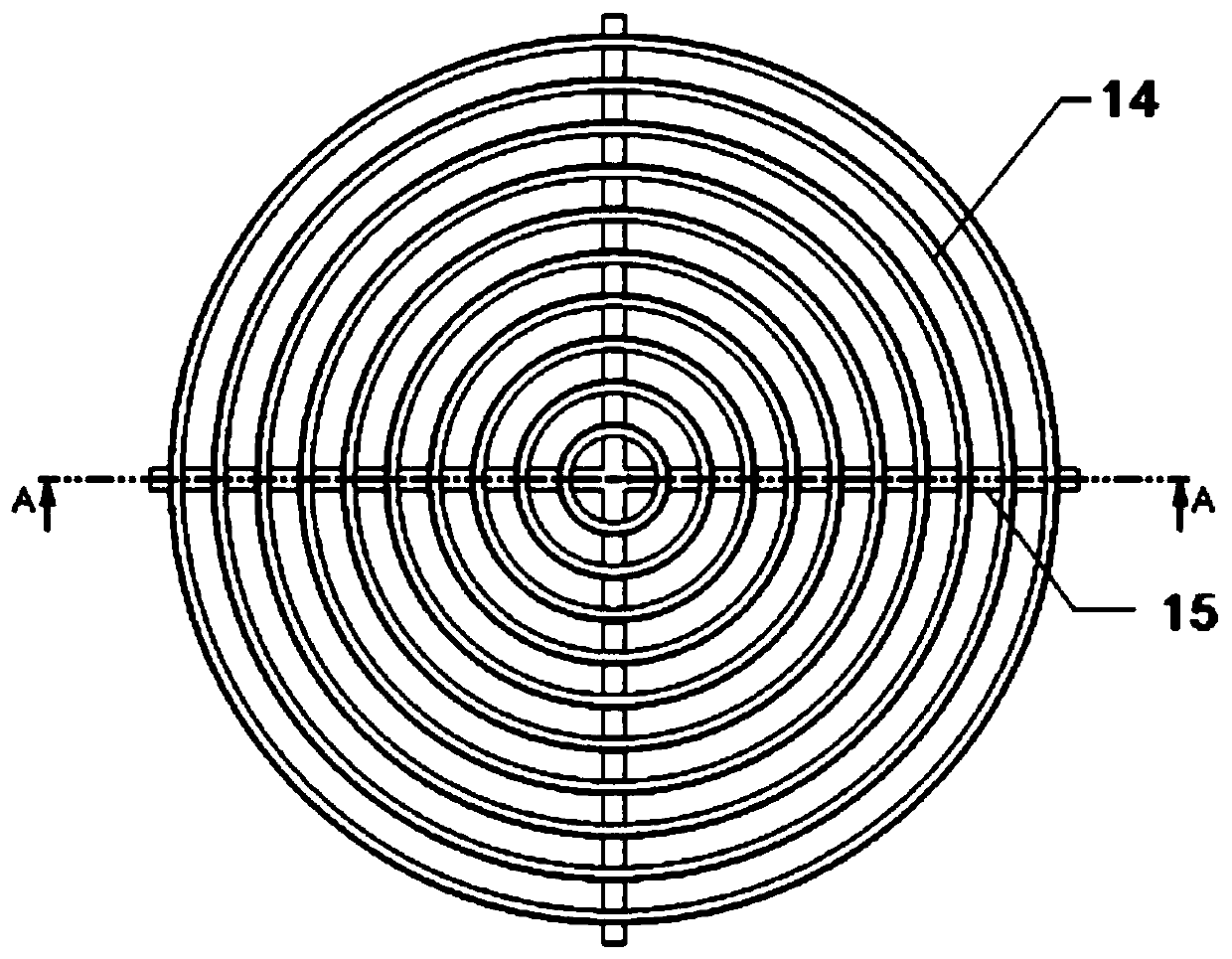

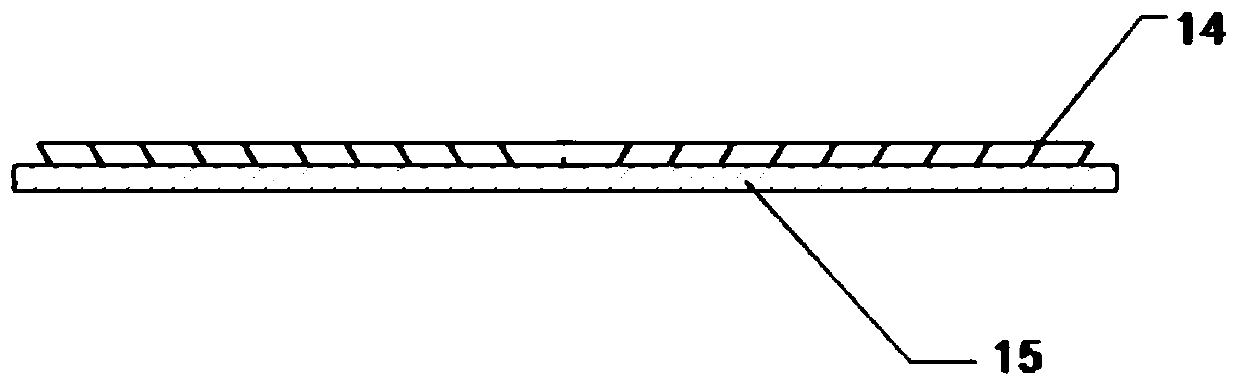

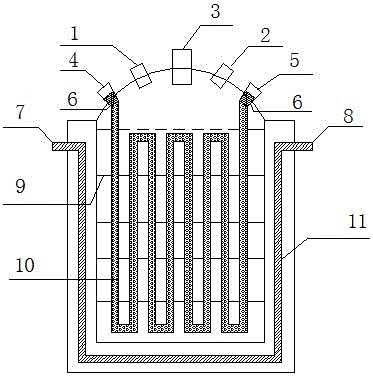

Static flotation column suitable for coarse particle recycling

The invention relates to a static flotation column suitable for coarse particle recycling, belongs to the technical field of mineral flotation and solves problems of unstable running, poor adaptability, small processing capacity, poor separation effect and failure to meet requirements on coarse particle slime recycling of the existing flotation column. The static flotation column comprises a firstcolumn body and a second column body; each of the first column body and the second column body is of a barrel-shaped structure; the upper part of the second column body penetrates after passing through a bottom plate of the first column body and is hermetically nested in the first column body; a feeding distributor is arranged in the space from a top opening of the second column body to a top opening of the first column body; the feeding distributor is connected with a feeding pipe; a water distribution pipe connected with a flush water pump is arranged above the feeding distributor; an overflowing groove is formed in the upper outer periphery of the first column body; and the bottom of the first column body is connected with the bottom of the second column body by a flowing guiding pipeto form a fluid circulation loop. The flotation column disclosed by the invention is stable to run, good in separation effect, and capable of being widely applied in coarse particle coal slime recycling.

Owner:CHINA UNIV OF MINING & TECH

Deep processing method of non-caking coal or feebly caking coal

The invention discloses a deep processing method of non-caking coal or feebly caking coal, which comprises the following steps: performing medium-and-low-temperature carbonization reaction on non-caking coal or feebly caking coal to generate coal gas, semicoke and coal tar; treating the coal tar as follows: inputting the coal tar material, oil gas obtained through delayed coking reaction and a hydrocracking liquid-phase product into a distillation tower, and distilling out naphtha fractions, carbolic-oil-containing fractions, wax oil fractions and tower bottom oil; mixing the naphtha fractions with hydrogen, and inputting into a naphtha hydrofining reaction section; dephenolizing the carbolic-oil-containing fractions to obtain dephenolized oil, mixing with the wax oil fractions, and inputting into a hydrotreating reaction section; fractionating the hydrotreating reaction liquid phase into light fractions and heavy fractions, and performing hydrocracking on the heavy fractions; and inputting the tower bottom oil obtained through distillation into a delayed coker. Compared with the prior art, the method disclosed by the invention performs sufficient deep processing on coal, improves the yield of light fuel oil produced from coal tar, and simultaneously prolongs the service life of a catalyst in a hydrogenation device.

Owner:中铝能源有限公司

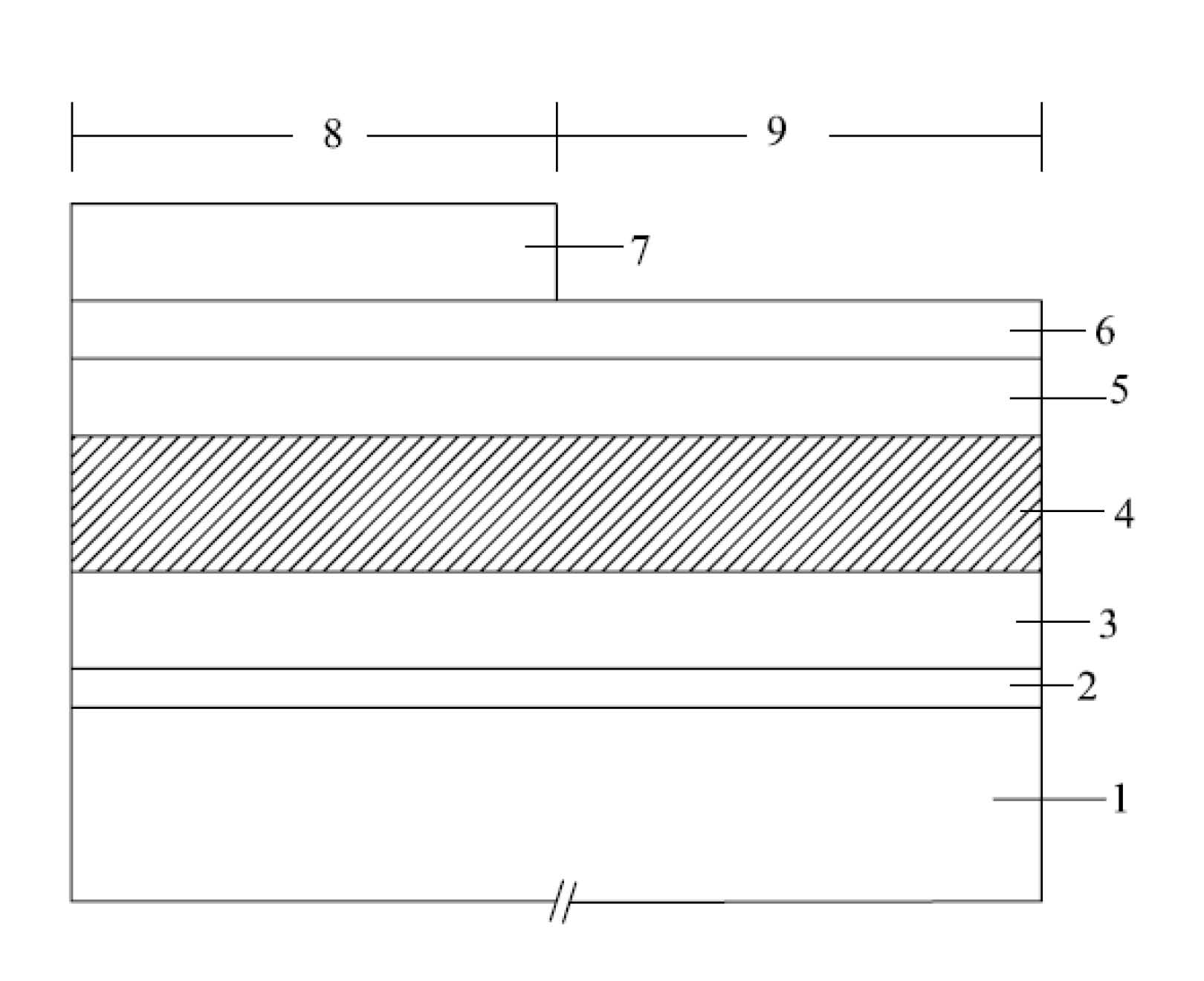

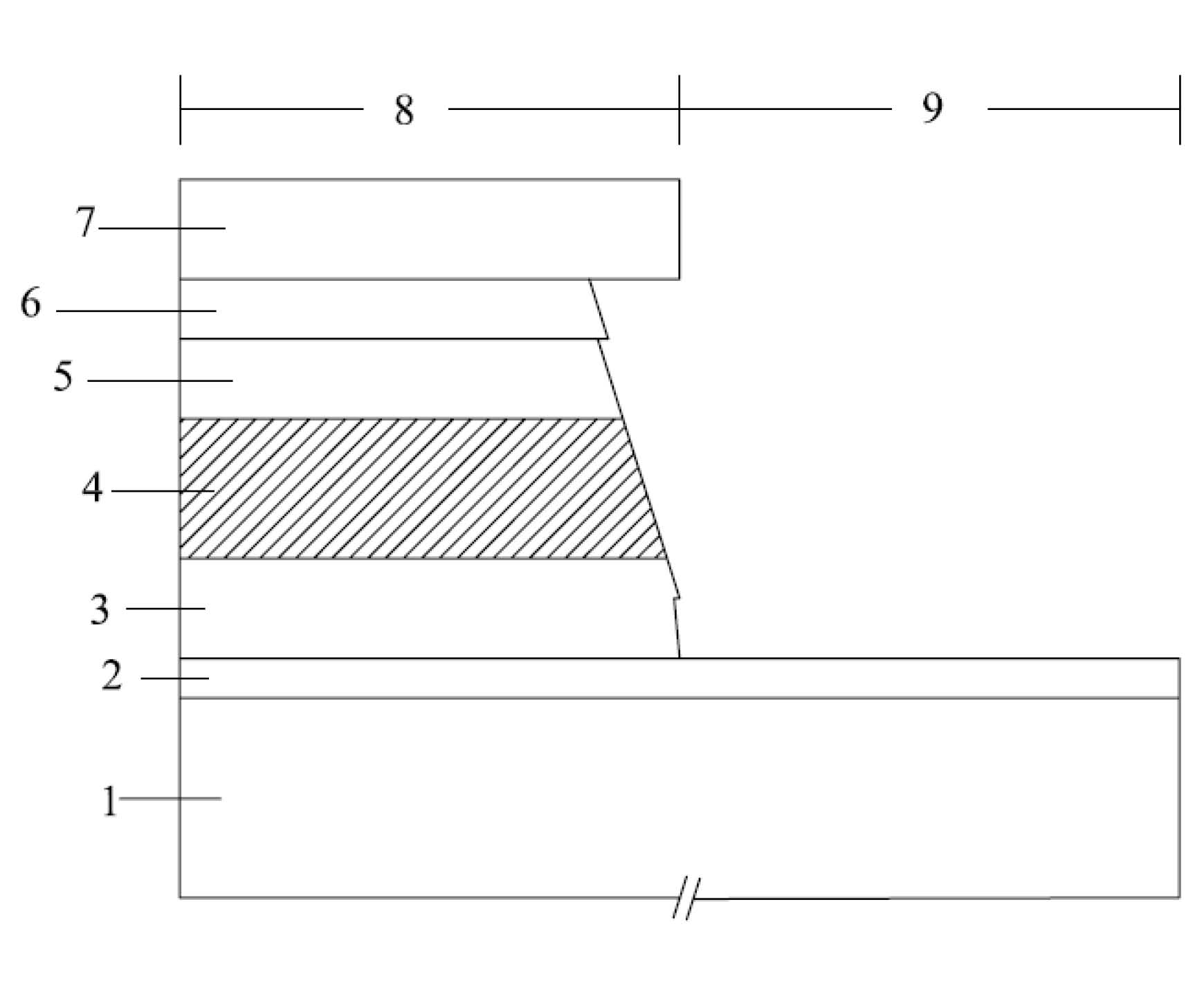

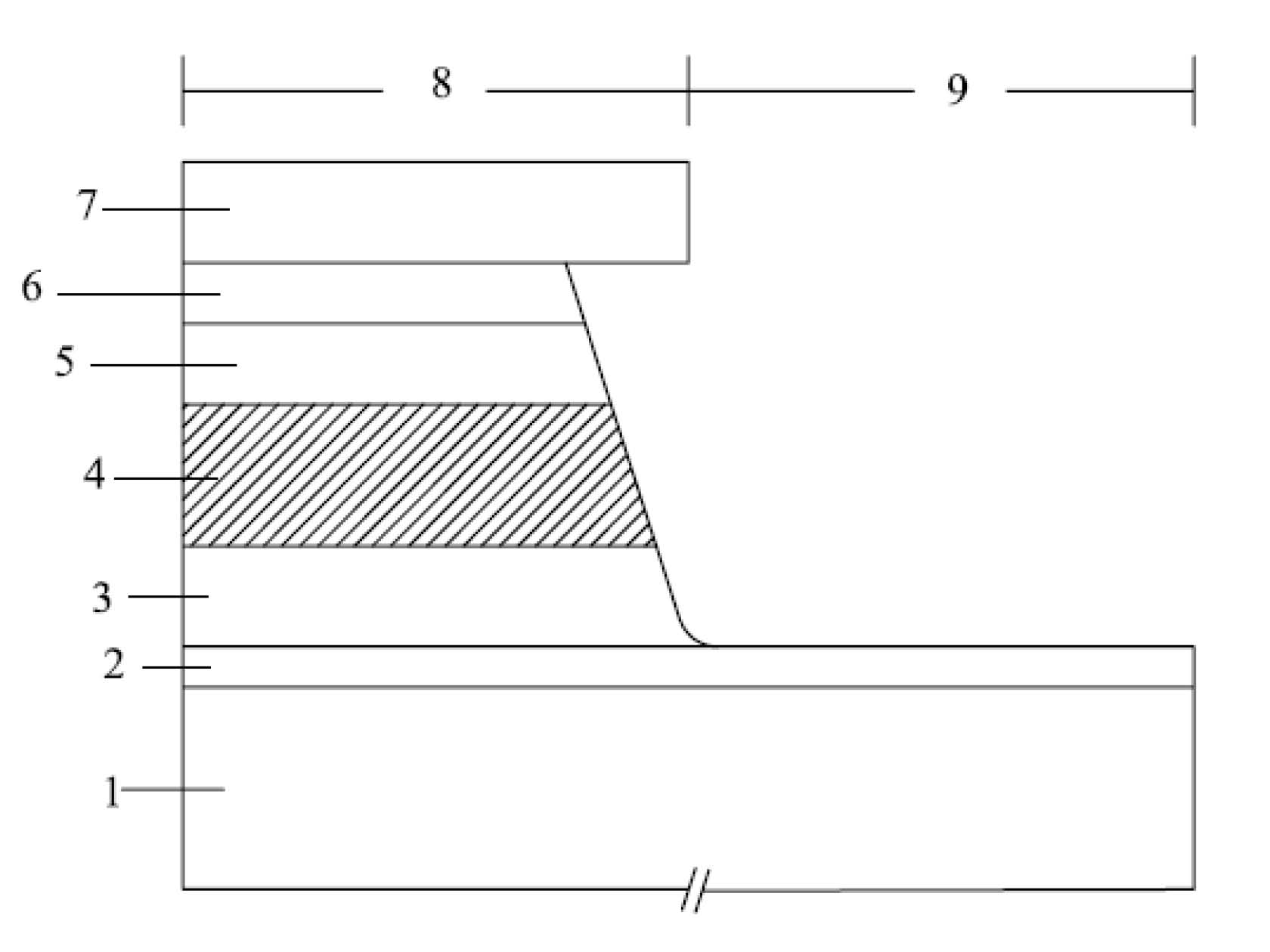

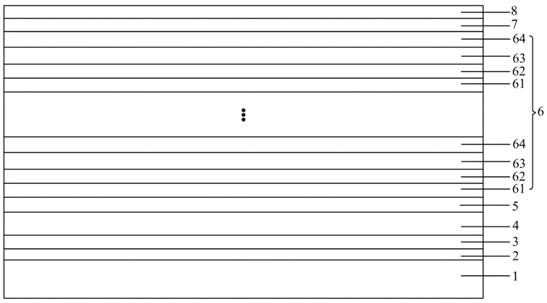

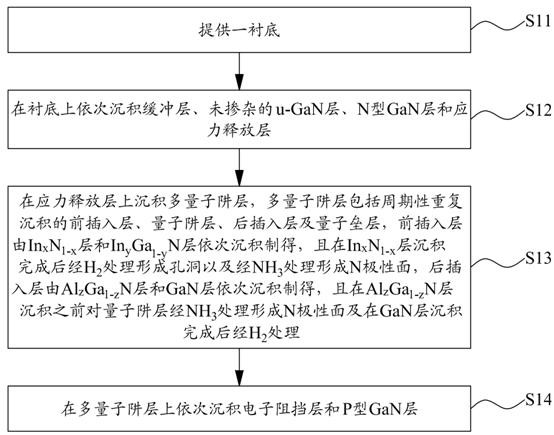

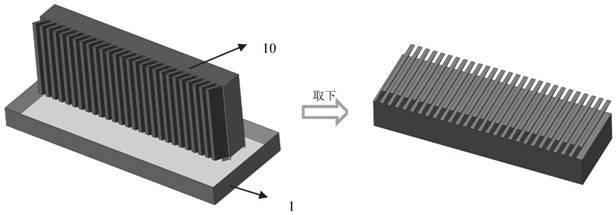

Light emitting diode epitaxial wafer and manufacturing method thereof

ActiveCN114824003AEvenly distributedFit tightlySemiconductor devicesElectrical polarityElectron blocking layer

The invention provides a light emitting diode epitaxial wafer and a manufacturing method thereof. The epitaxial wafer comprises a substrate, a buffer layer, an undoped u-GaN layer, an N-type GaN layer, a stress release layer, a multi-quantum well layer, an electron barrier layer and a P-type GaN layer, the multi-quantum well layer comprises a front insertion layer, a quantum well layer, a rear insertion layer and a quantum barrier layer; the front insertion layer comprises an In < x > N < 1-x > layer and an In < y > Ga < 1-y > N layer, and the contact surface of the In < x > N < 1-x > layer and the In < y > Ga < 1-y > N layer is processed by H2 to form a hole and processed by NH3 to form an N polar surface; the rear insertion layer comprises an Al < z > Ga < 1-z > N layer and a GaN layer, the surface, in contact with the Al < z > Ga < 1-z > N layer, of the quantum well layer is subjected to NH3 treatment to form an N polar surface, and the surface, in contact with the quantum barrier layer, of the GaN layer is subjected to H2 treatment. According to the invention, the problems of low luminous efficiency and low wavelength uniformity of the existing light-emitting diode are solved.

Owner:JIANGXI ZHAO CHI SEMICON CO LTD

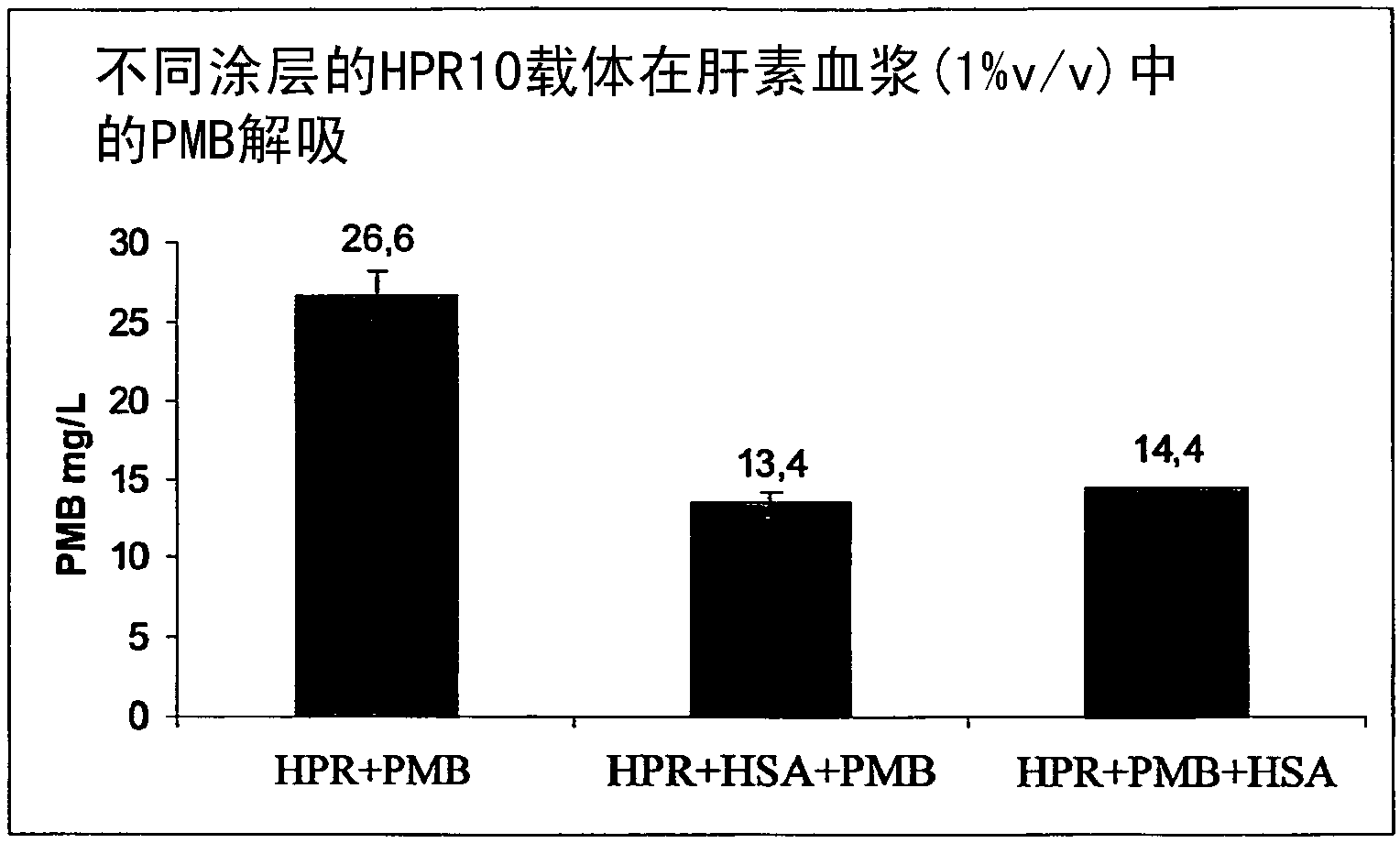

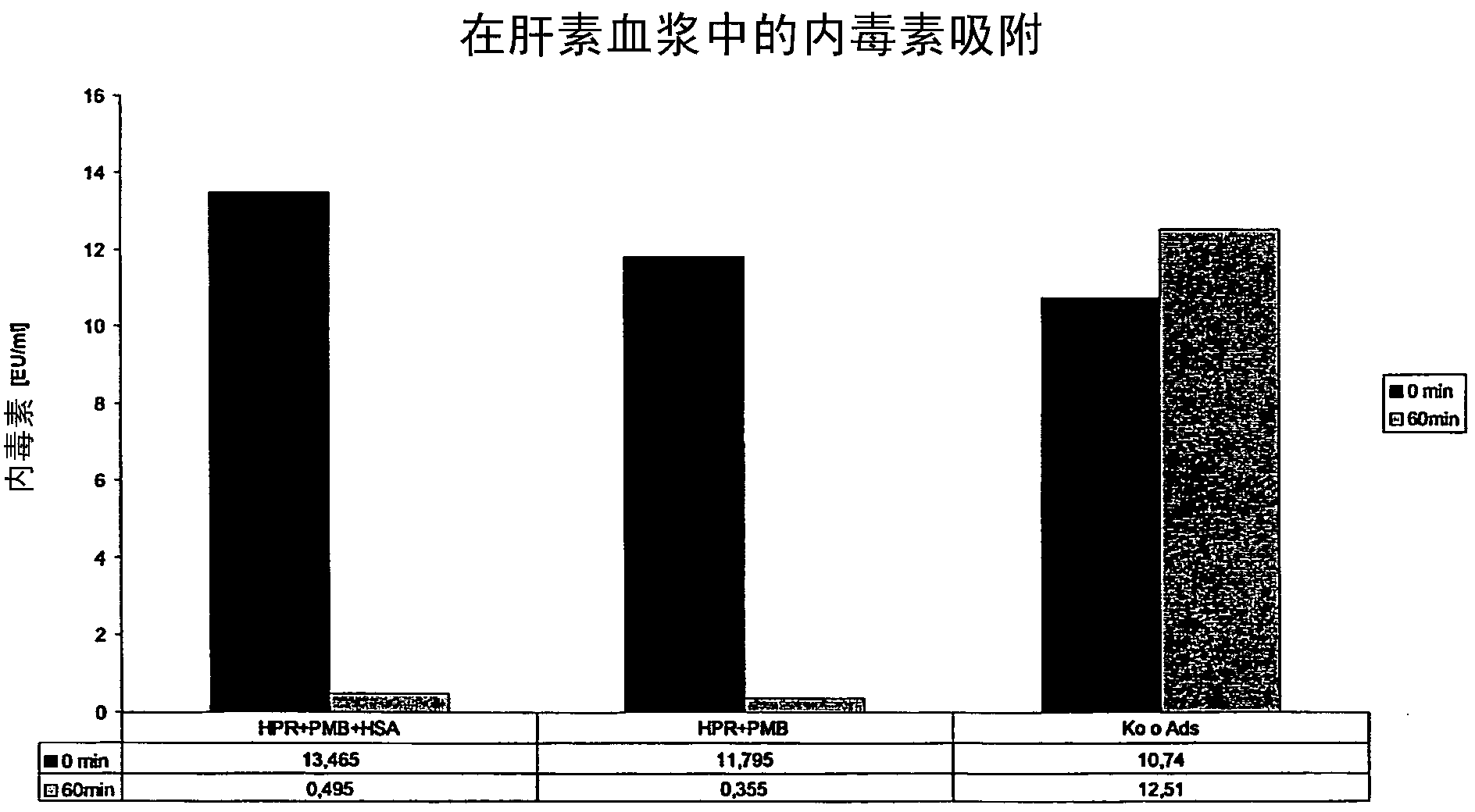

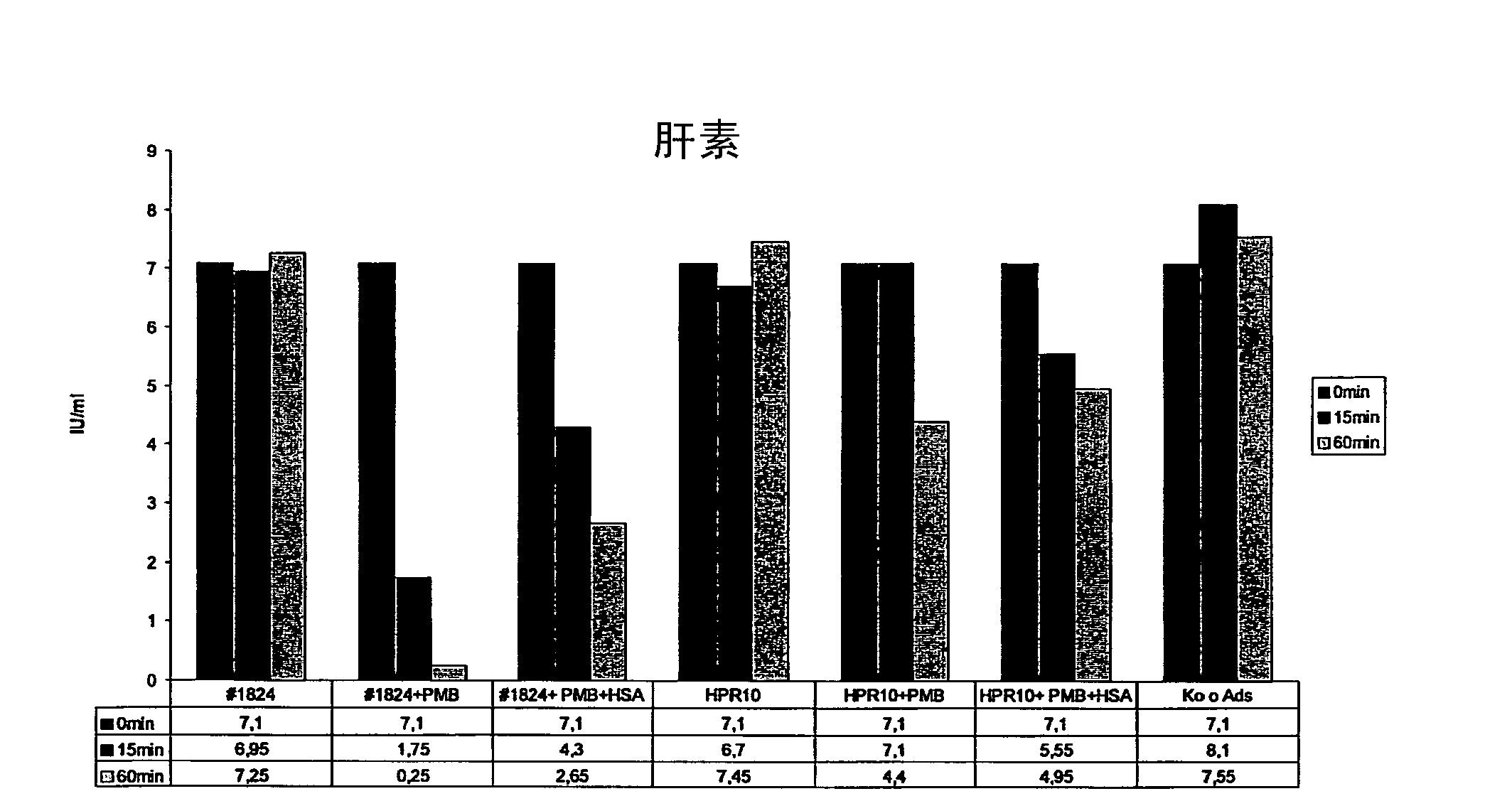

Novel sorbent for endotoxins

InactiveCN103221079AImprove abilitiesHigh speedOther chemical processesOther blood circulation devicesPorous substrateWater insoluble

The invention relates to a sorbent for removing endotoxins from a biological liquid, comprising a water-insoluble, porous substrate having a neutral, hydrophobic surface, wherein the surface of the substrate has an adsorbent coating made of polymyxin and albumin, wherein polymyxin and albumin are bonded to the surface of the substrate in a noncovalent manner. The invention further relates to a method for producing such a sorbent. The sorbent is used in extracorporeal blood purification, in particular in order to treat individuals who have sepsis.

Owner:FRESENIUS MEDICAL CARE DEUTSCHLAND GMBH

Cellular V2O5-Pr6O11-SbPO4/TiO2 based low-temperature sulfur-resistant denitration catalyst and preparation method thereof

InactiveCN106000435AImprove oxygen storage capacityImprove denitrification activityGas treatmentPhysical/chemical process catalystsSulfurTitanium

The invention discloses a cellular V2O5-Pr6O11-SbPO4 / TiO2 based low-temperature sulfur-resistant denitration catalyst and a preparation method thereof. The cellular V2O5-Pr6O11-SbPO4 / TiO2 based low-temperature sulfur-resistant denitration catalyst is prepared from the following components: 1-5wt% of V2O5, 2-6wt% of Pr6O11, 1.5-5wt% of SbPO4 and 84-95.5wt% of a TiO2-based carrier, wherein the TiO2-based carrier comprises one or more of titanium dioxide, titanium tungsten powder and titanium tungsten silicon powder. The invention further discloses a preparation method of the cellular catalyst. The prepared catalyst has high denitration efficiency at the smoke (exhaust gas) temperature of 175-300 DEG C, and also has excellent sulfur resistance.

Owner:LONGYAN ZIJIN INNOVATION RES INST

Reduction washing-fade dyeing technology

The invention discloses a reduction washing-fade dyeing technology. The technological process starts from a semi-finished product of white cloth and comprises: a dye suspension padding process, a first drying process, a fixing liquid padding process, a first steaming process, a reduction liquid padding process, a second steaming process, a first washing process, a soap boiling process, a second washing process and a second drying process, wherein the dye suspension in the dye suspension padding process is prepared by compounding a vat dye and a reactive dye in a ratio of (3:1) to (4:3). In the invention, the vat dye is compounded with the reactive dye, the two dyes are applied to the cloth surface at the same time, thus the dyeing of the vat dye is uniform, and the dyeing performance of the reactive dye can be improved; and after the fabric dyed by the technology disclosed by the invention is made into a finished product, an old-like style can be obtained through chlorine bleaching.

Owner:张家港市双盈印染有限公司

Novel water treatment air floating tank

InactiveCN103848466AIncrease contact timeGood adhesionWater/sewage treatment by flotationSuspended matterMechanical engineering

The invention provides a novel water treatment air floating pool. The air floating tank comprises a tank body, wherein a first partition plate, a second partition plate and a third partition plate are sequentially arranged in the tank body; the first partition plate, the second partition plate and the third plate sequentially divide the tank into an impact contact chamber, an adhesion contact chamber, an air floating separation chamber and a diversion water outlet chamber; the impact contact chamber and the adhesion contact chamber are communicated at the tank bottom by a first channel, the air floating separation chamber and the diversion water outlet chamber are communicated at the tank bottom by a second channel, air dissolving releasers are uniformly arranged at the bottom parts of the impact contact chamber and the adhesion contact chamber, a pipe opening of a raw water inlet pipe is arranged at the upper part of the impact contact chamber, a hydraulic slag removal system is arranged above the impact contact chamber, and a mechanical slag removal system is arranged above the air floating separation chamber. With the novel water treatment air floating tank, the mutual action between micro air bubbles and suspended substances is remarkably improved to realize the effective adhesion of micro air bubbles and suspended substances, and the capacity of resisting water quality change and the water purification effect are improved.

Owner:SHANDONG JIANZHU UNIV

Two-stage combined hydrogenation process of coal tar

The invention discloses a two-stage combined hydrogenation process of coal tar. The process comprises the steps of: (a) sending a coal tar raw material into a hydrogenation reaction section for a hydrotreating reaction; (b) carrying out a gas-liquid separation on an effluent from the hydrogenating reaction section, and sending a separated liquid phase into the a fractionation device, so as to distillate out a gasoline fraction, a diesel fraction and a heavy fraction; (c) sending at least part of the heavy fraction from the step (b) into a hydrocracking reaction section for a hydrocracking reaction; (d) sending an effluent from the hydrocracking reaction section into a hot high pressure separator, in order to separate out a gas phase and a liquid phase, and sending at least part of the liquid phase to the hydrotreating reaction section in the step (a); (d) sending an effluent from the hydrocracking reaction section into a hot high pressure separator, in order to separate out a gas phase and a liquid phase, and sending at least part of the liquid phase to the hydrotreating reaction section in the step (a); Compared with the prior art, the method provided by the invention improves the yield of light fuel production from coal tar, prolongs the service life of a catalyst, and increases operation cycle of the device.

Owner:上海竣铭化工工程设计有限公司

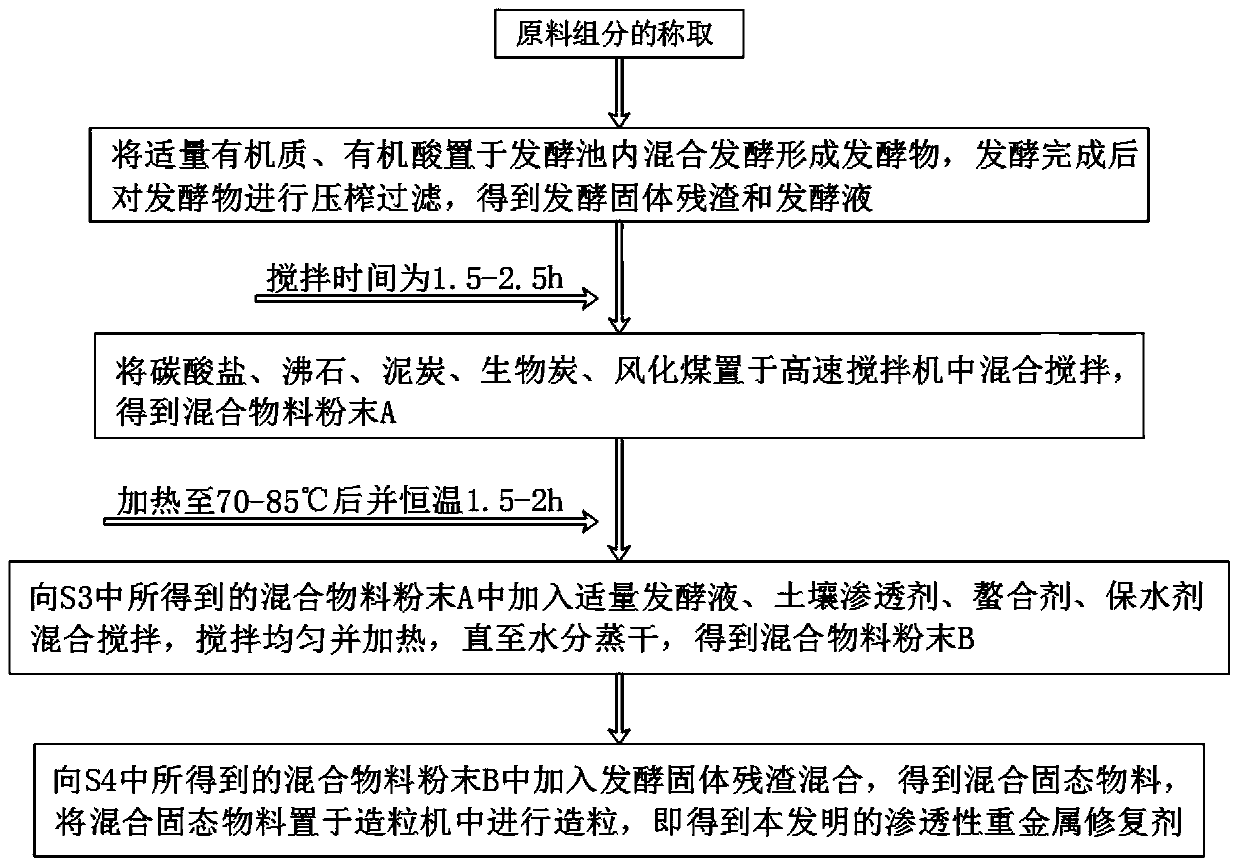

Self-permeating type soil heavy metal repair agent and preparation method thereof

InactiveCN110591719AGood physical propertiesImprove fat retention capacityAgriculture tools and machinesRotary stirring mixersFood chainIon exchange

The invention discloses a self-permeating type soil heavy metal repair agent and a preparation method thereof, and belongs to the technical field of repair agent preparation. According to the self-permeating type soil heavy metal repair agent and the preparation method thereof, organic matter is mixed with a base material of organic acid, the promoting property of the repair agent on growth and development of plants is effectively improved, physical properties of repaired soil are improved, activities of microorganisms and soil organisms are promoted, nutrient elements in the soil are promotedto be decomposed, and meanwhile, air permeability, permeability and adsorbability of the soil are changed; by addition of mineral improvers such as zeolite, peat, charcoal, weathered coal and the like, on one hand, reaction performance such as adsorption, ion exchange and the like of heavy metal elements is improved, heavy metal pollutants such as cadmium, chromium, lead and the like in soil canbe cured and passivated, bio-availability of the heavy metal pollutants and mobility in soil are reduced, risks that the pollutants are absorbed by crops and transferred to food chains are reduced, and on the other hand, physical and chemical properties of the soil are improved.

Owner:杨涛

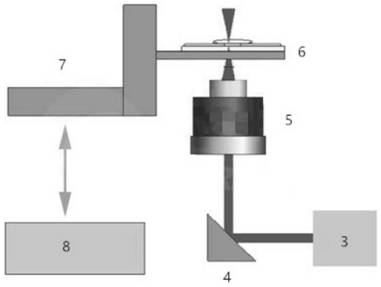

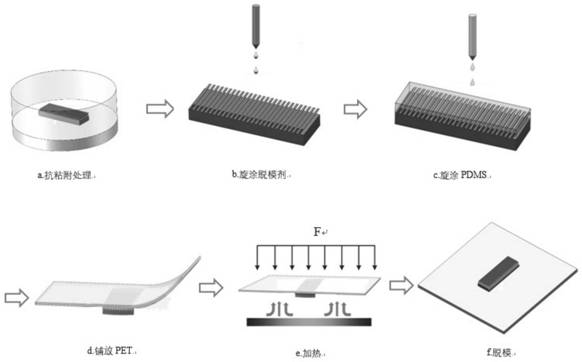

Preparation method of AR diffraction optical waveguide imprinting mold, soft mold and application

ActiveCN112026073AImprove printing accuracyMeet the precision requirementsFurnace typesElectroforming processesGratingComputer printing

The invention relates to a preparation method of an AR diffraction optical waveguide imprinting mold, a soft mold and application. The preparation method comprises the specific steps that an electroforming mask is printed on a nickel substrate through a two-photon polymerization micro-nano 3D printer; nanosecond pulse micro electroforming is utilized, electroforming is conducted on the obtained nickel substrate with the mask, and an inclined grating metal nickel mold is obtained; and the manufactured inclined grating metal nickel mold serves as a female mold, the female mold is coated with a pattern layer polymer PDMS, PET is attached to the PDMS, imprinting is conducted on the mold, uncovering type demolding is adopted, the soft mold copied at a time is obtained, the steps of PDMS coating, PET attaching, imprinting and uncovering type demolding are repeated, and finally the composite soft mold with a plurality of PDMS soft mold arrays arranged on one piece of PET is prepared. High-precision, low-cost and efficient manufacturing of the large-area AR diffraction optical waveguide imprinting mold is achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

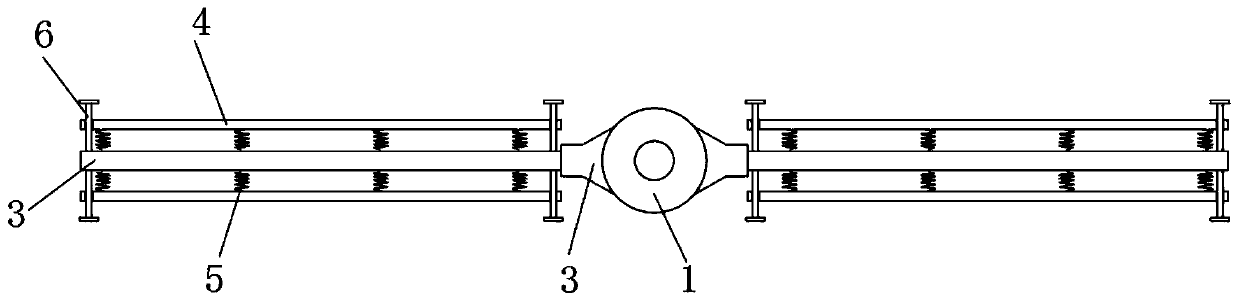

Flotation column device

The invention relates to mineral separation equipment, and discloses a flotation column device. The flotation column device comprises a different-diameter flotation column and a jet flow mineralization system used for supplying mineral pulp to the different-diameter flotation column; the different-diameter flotation column comprises an upper cylindrical section and a lower cylindrical section withthe diameter being smaller than that of the upper cylindrical section; the upper cylindrical section and the lower cylindrical section are connected through a conical transition section, and the lower cylindrical section is connected with a bottom conical section; a bubble collecting tank is arranged on the outer side of the upper end of the upper cylindrical section and connected with a bubble collecting pipe; and a tailing collecting pipe is arranged on the lower part of the bottom conical section. According to the flotation column device, colliding and adhesion of particles and bubbles areachieved in an appropriate turbulent environment; in a relatively-static fluid environment and under the large column body diameter, deadhesion of the coarse particles is reduced advantageously, meanwhile separation of useful minerals from gangue minerals is improved, and thus the separation efficiency is effectively improved; and the flotation column device has the advantages of being small in floor space, low in energy consumption and good in separation effect.

Owner:CENT SOUTH UNIV

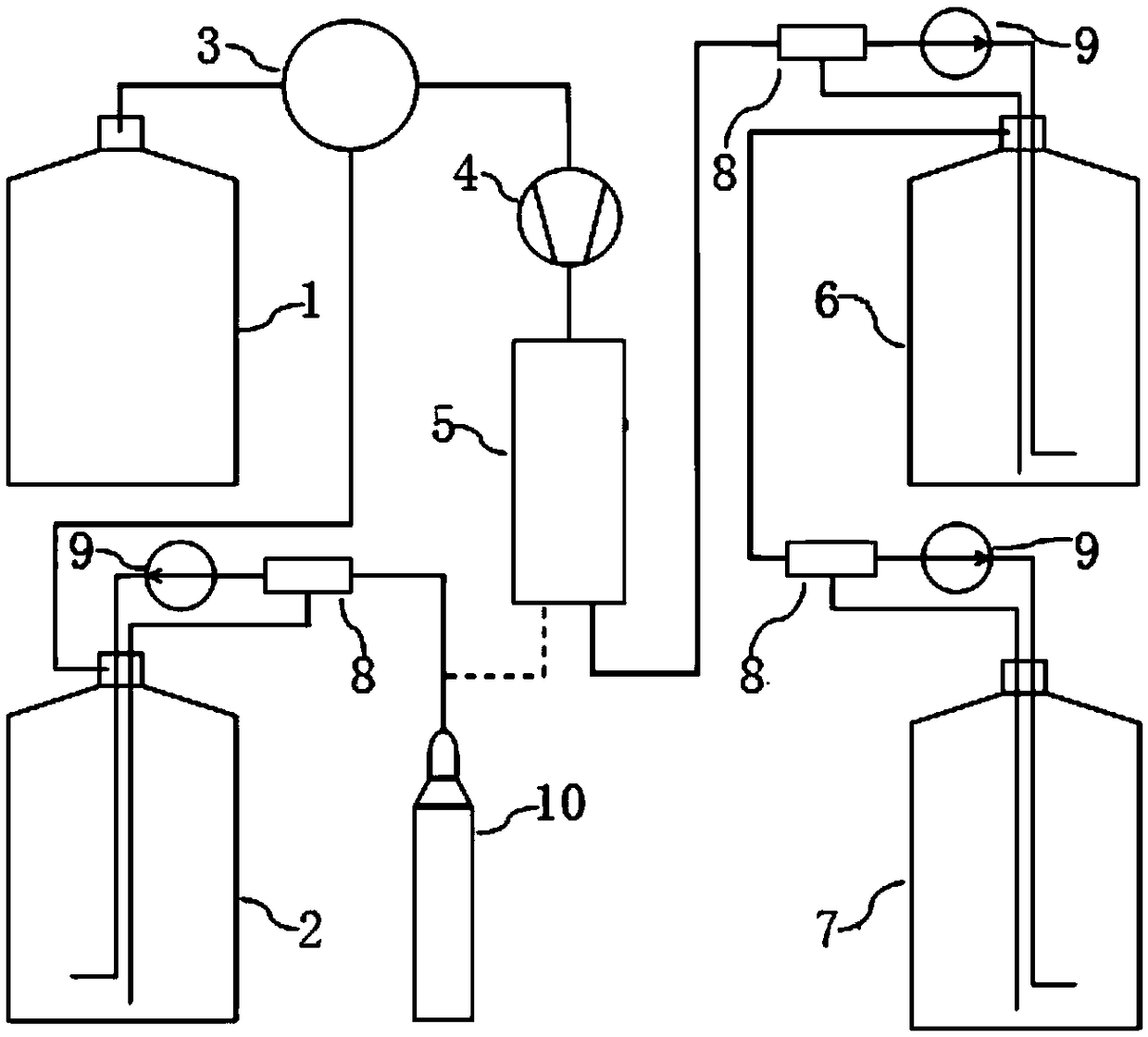

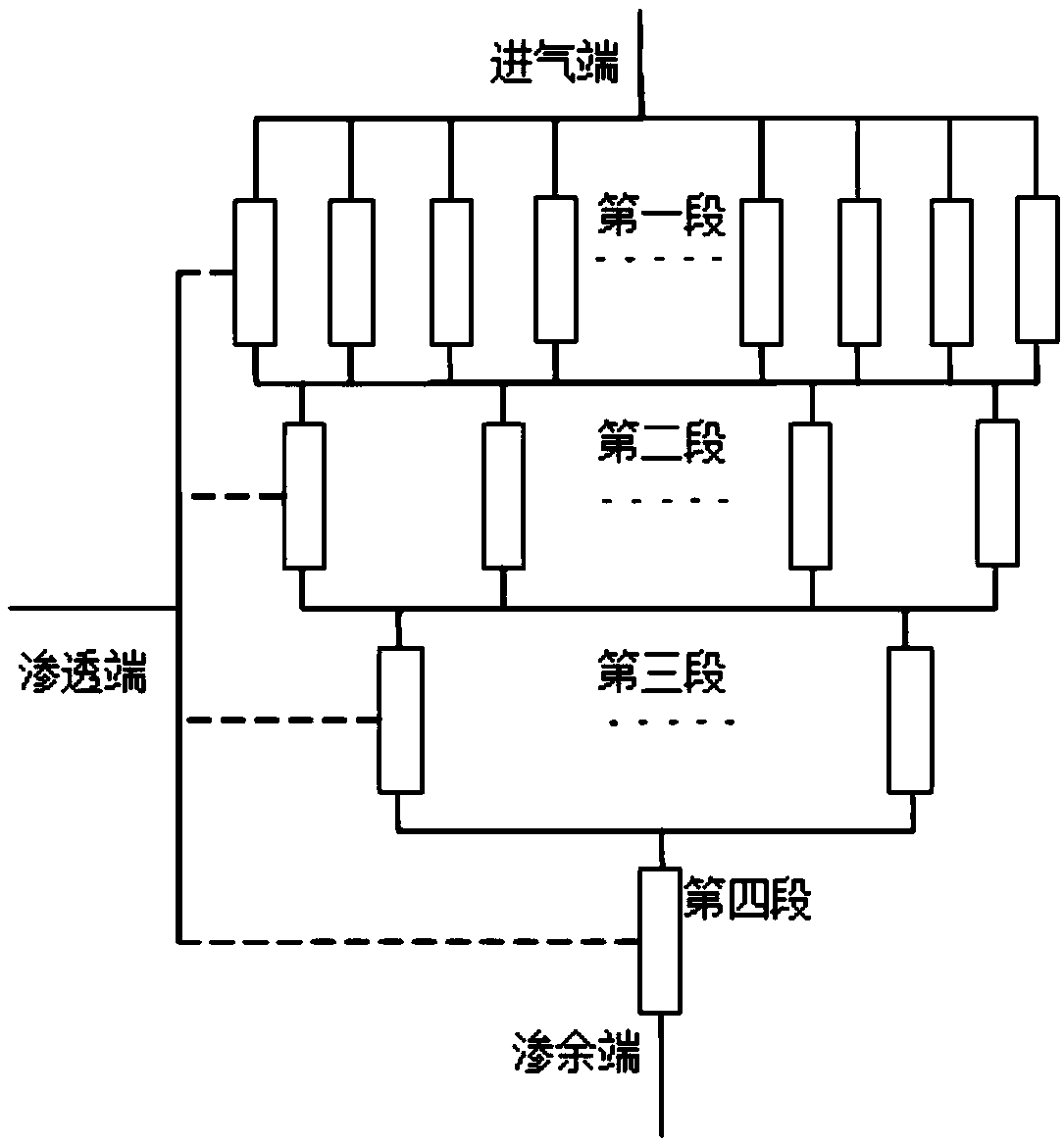

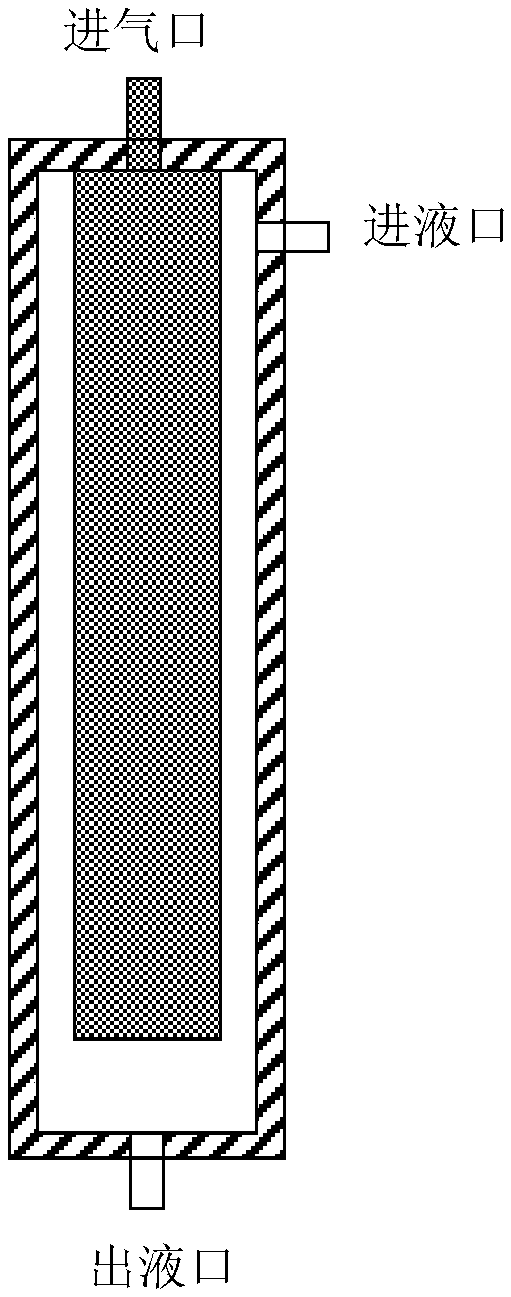

Method and system for collecting aromatic substances and adding same to wine during fermentation

The invention discloses a method and system for collecting aromatic substances and adding the same to wine during fermentation. Fermentation mixture discharged from fermentation of the wine and mixture obtained from desorption and extraction of the wine are delivered to a membrane separation device, unwanted and harmful substances are separated from the mixture, aromatic substances needed are concentrated, and the concentrated mixture is then subjected to absorption of the aromatic substances at low temperature by using the wine of the previous subsequent stages as an absorbent. Thus, the aromatic substances in wine fermentation broth can be well transferred to the wine serving as the absorbent, the wine has more aromatic substances containing highly volatile aromatic substances that are completely discharged by carbon dioxide mixture produced in previous fermentation, and the wine has unprecedented aroma. The method is easy to implement and can be implemented by the aid of existing equipment and process conditions, and easy application to large-scale production is achieved.

Owner:杨元庆

Low-pressure adsorption natural gas storage tank

InactiveCN106015928AImprove adsorption capacityImprove responseVessel geometry/arrangement/sizeContainer filling methodsActivated carbonDesorption

A low-pressure adsorption natural gas storage tank disclosed by the present invention is composed of a tank body and an external jacket, wherein the tank body is equipped with an air inlet, an air outlet, an inlet for activated carbon, an inlet for a phase change reaction agent, and a phase change reaction agent. Variable reaction agent outlet, the inside of the tank has an activated carbon partition layer and a stainless steel coil, the outer jacket is equipped with a circulating cooling water pipe, and is equipped with a water inlet and a water outlet. Equipped with a nano filter core with a special structure, the stainless steel coil is filled with a phase change reaction agent. A low-pressure adsorption natural gas storage tank of the present invention has a simple structure and is convenient to operate. The phase change reactant and external circulating cooling water are used to absorb and release heat inside the storage tank, which is beneficial to the adsorption and desorption reactions of natural gas. , to avoid reducing the adsorption and desorption of natural gas due to temperature.

Owner:NINGXIA BAOTA PETROCHEM SCI & TECH IND DEV

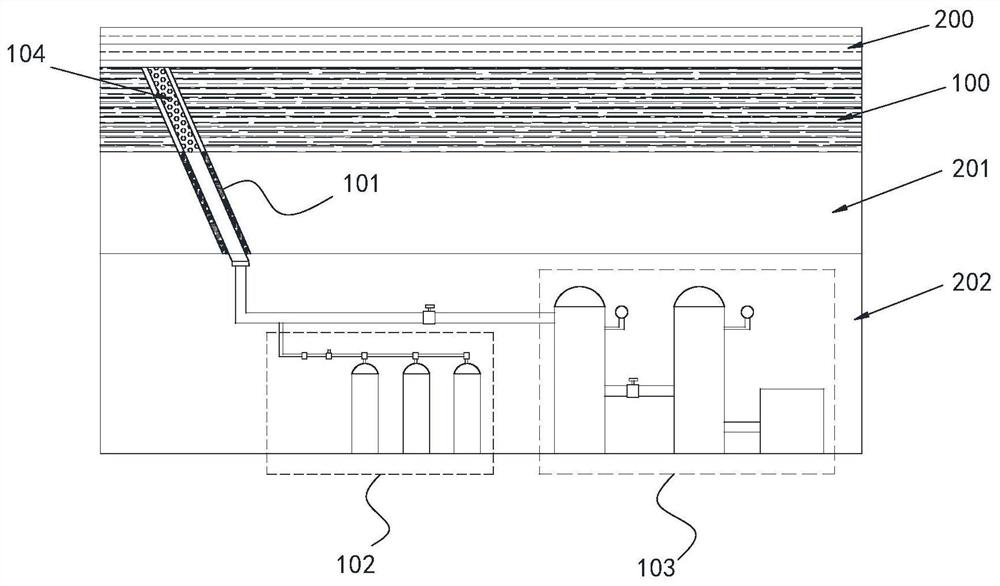

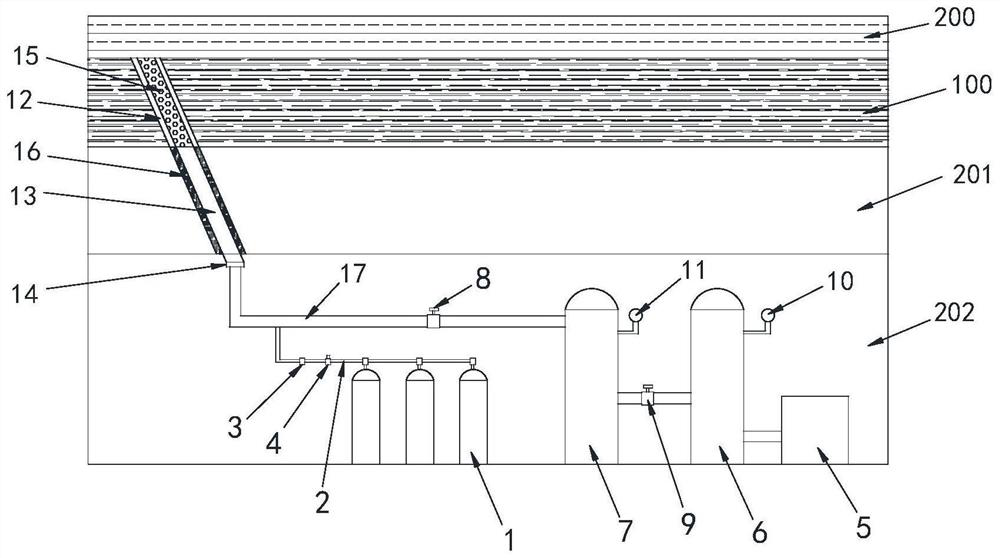

Mine gas permeability improving method and device

PendingCN113236338AImprove permeabilityReduce adsorptionFluid removalGas removalThermodynamicsFracturing fluid

The invention relates to the technical field of unconventional natural gas extraction, in particular to a mine gas permeability improving method and device. The device comprises a pipeline, a liquid CO2 supply unit and a fracturing fluid supply unit, wherein the inner end of the pipeline is used for being placed in a coal seam, and the outer end of the pipeline is connected with the liquid CO2 supply unit and the fracturing fluid supply unit in parallel; and after the fracturing fluid supply unit injects high-temperature and high-pressure fracturing fluid into the coal seam through the pipeline, the liquid CO2 supply unit injects liquid CO2 into the coal seam through the pipeline. The mine gas permeability improving method and device provided by the invention have the advantages that the permeability of the coal seam can be effectively improved, the desorption speed of coal bed gas (gas) in the coal seam is accelerated, and the extraction efficiency of the coal bed gas (gas) can be obviously improved.

Owner:中国煤炭地质总局勘查研究总院

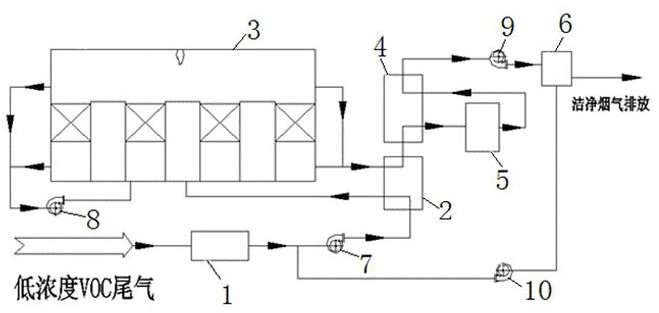

Anti-blocking combined process and system for high treatment efficiency of low-concentration VOC tail gas

PendingCN113701174ARaise the furnace temperatureReduce cloggingCombustion technology mitigationIncinerator apparatusChemistryMolecular sieve

The invention relates to an anti-blocking combined process and system with high treatment efficiency for low-concentration VOC tail gas. The process comprises the following steps of (1) pretreating the low-concentration VOC tail gas; (2) preheating; (3) conducting RTO incineration; (4) conducting high-temperature reverse burning; (5) preheating the tail gas by incinerated flue gas and conducting primary cooling on the flue gas; (6) conducting secondary cooling on the flue gas subjected to primary cooling and cooled and dewatered flue gas; (7) deacidifying the flue gas subjected to secondary cooling; (8) heating and drying the cooled and dewatered flue gas; and (9) adsorbing the flue gas in a zeolite molecular sieve to remove secondary organic matters. According to the process and the system, the waste heat of low-temperature flue gas is recycled, the charging temperature of the waste gas is increased, and the adsorption of high-waste boiling substances in the charging waste gas on a heat storage bed is reduced, so that the desorption of the high-waste boiling substances during flue gas discharge is reduced, meanwhile, the situation that amine organic matter decomposition product ammonia is adsorbed on the heat storage bed and directly enters a hearth to be decomposed is reduced, ammonia sources for synthesis of ammonium salt are reduced, and blockage caused by gathering of ammonium salt particles in a heat storage bed layer is reduced.

Owner:JIANGSU DAXIN ENVIRONMENTAL SCI & TECH

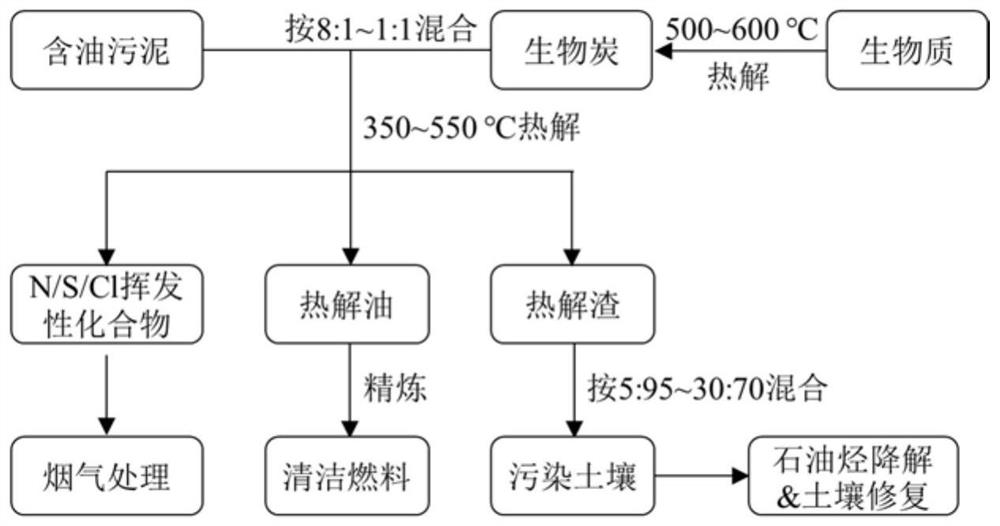

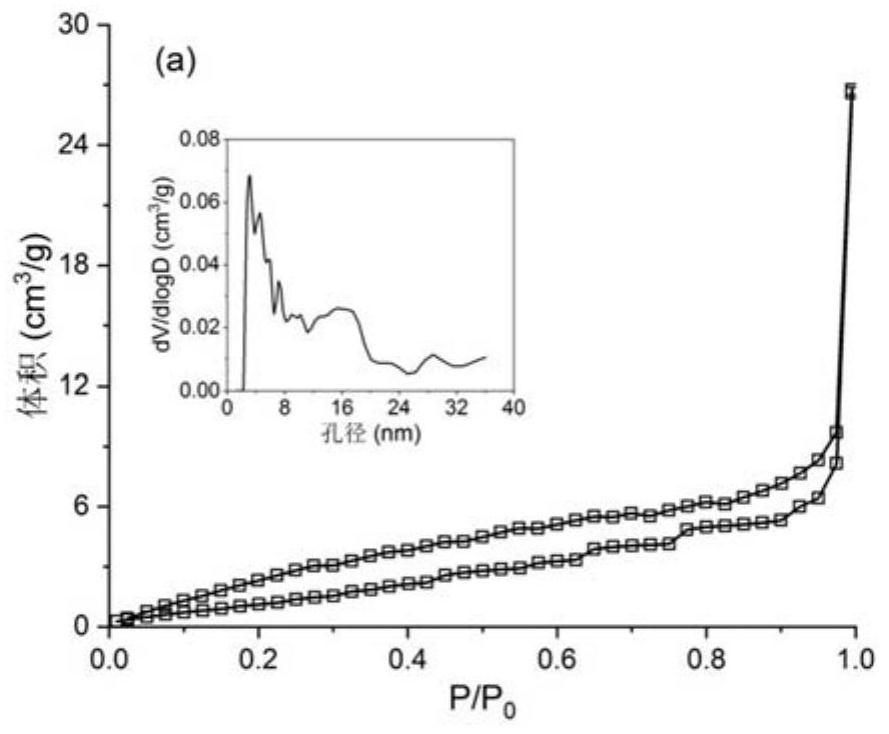

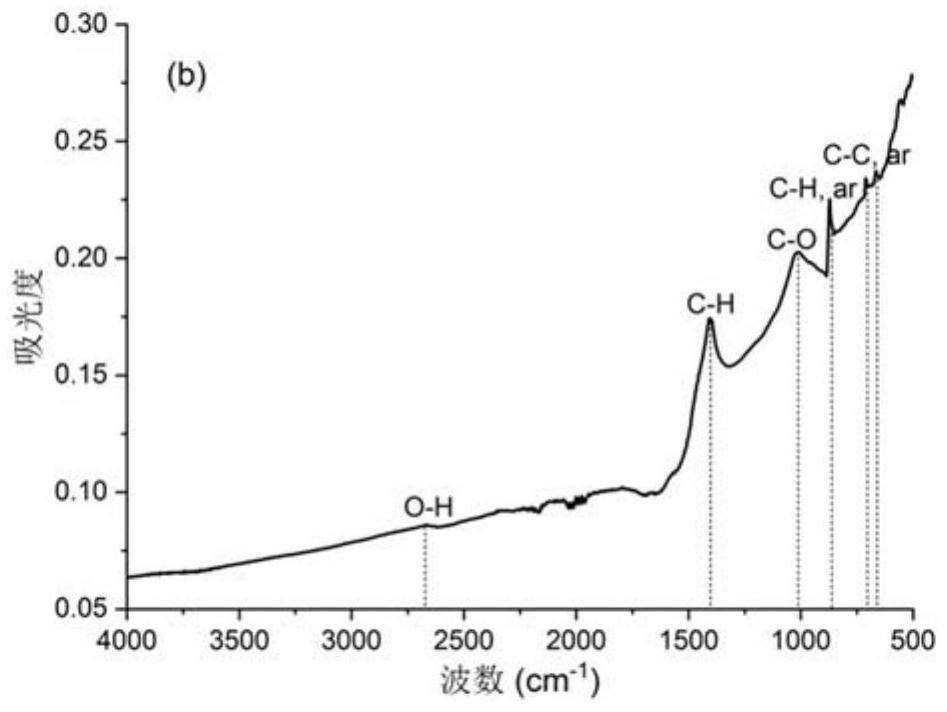

Oily sludge treatment method and soil remediation method

PendingCN114772890ARich pore structureRich in functional groupsSludge treatment by pyrolysisContaminated soil reclamationCatalytic pyrolysisSoil remediation

The invention provides an oily sludge treatment method and a soil remediation method.The oily sludge treatment method comprises the steps that after oily sludge and target biochar are evenly mixed according to a first preset mass ratio, catalytic pyrolysis reaction is conducted at the first preset temperature, efficient removal of petroleum hydrocarbon is achieved, and pyrolysis residues are obtained and used for soil remediation.

Owner:TIANJIN UNIV

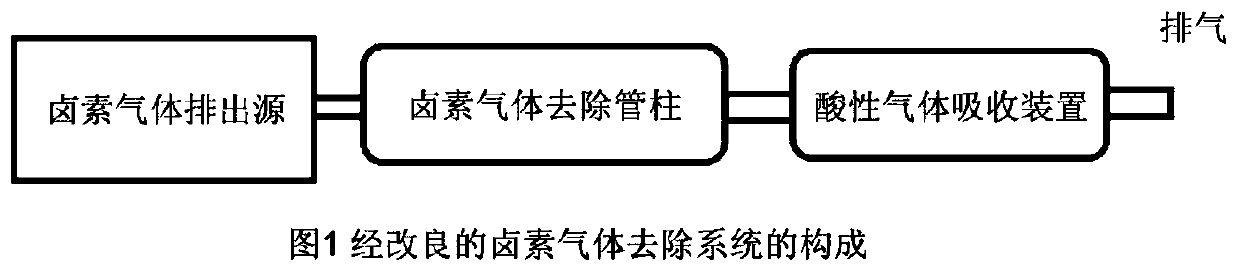

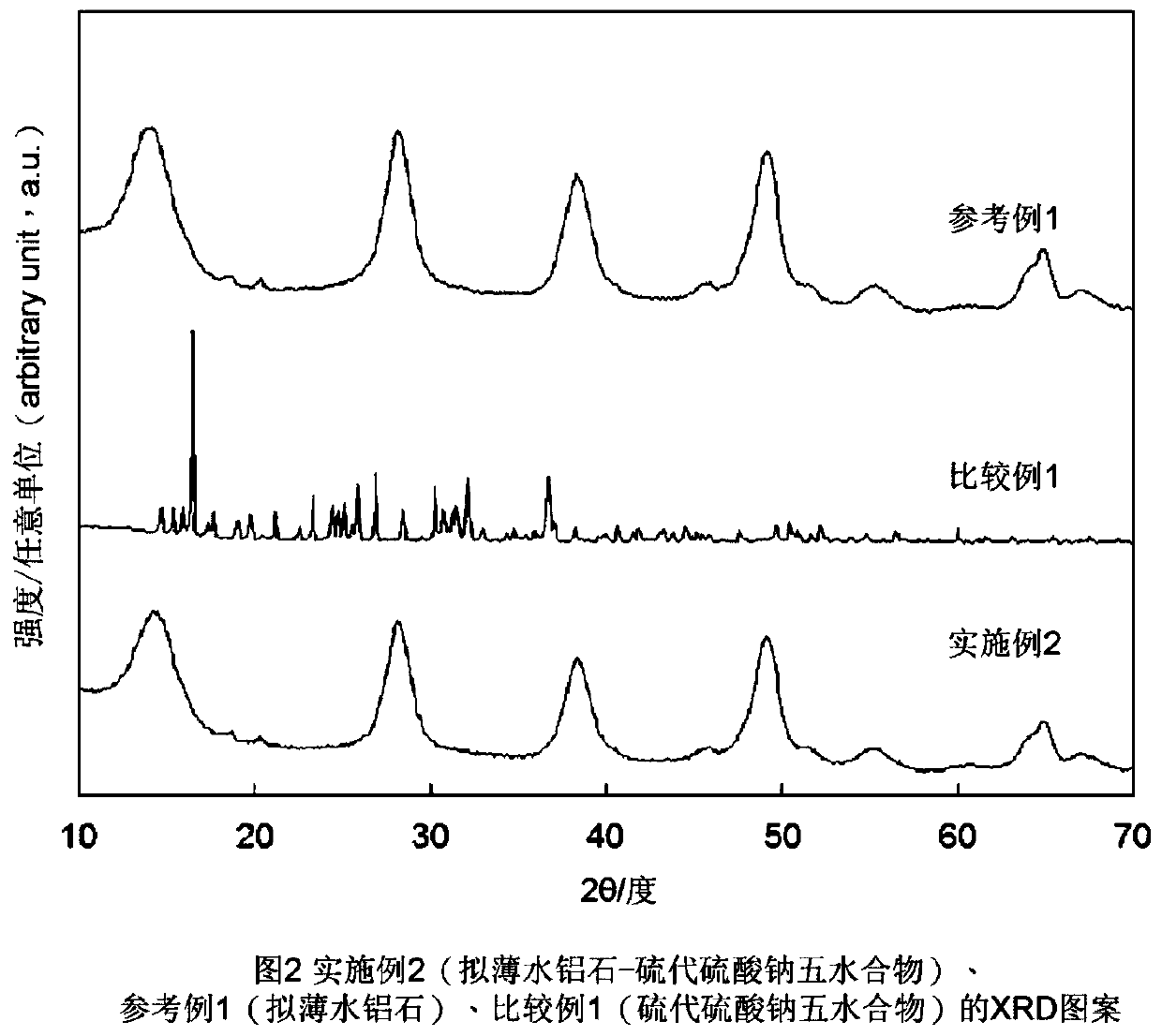

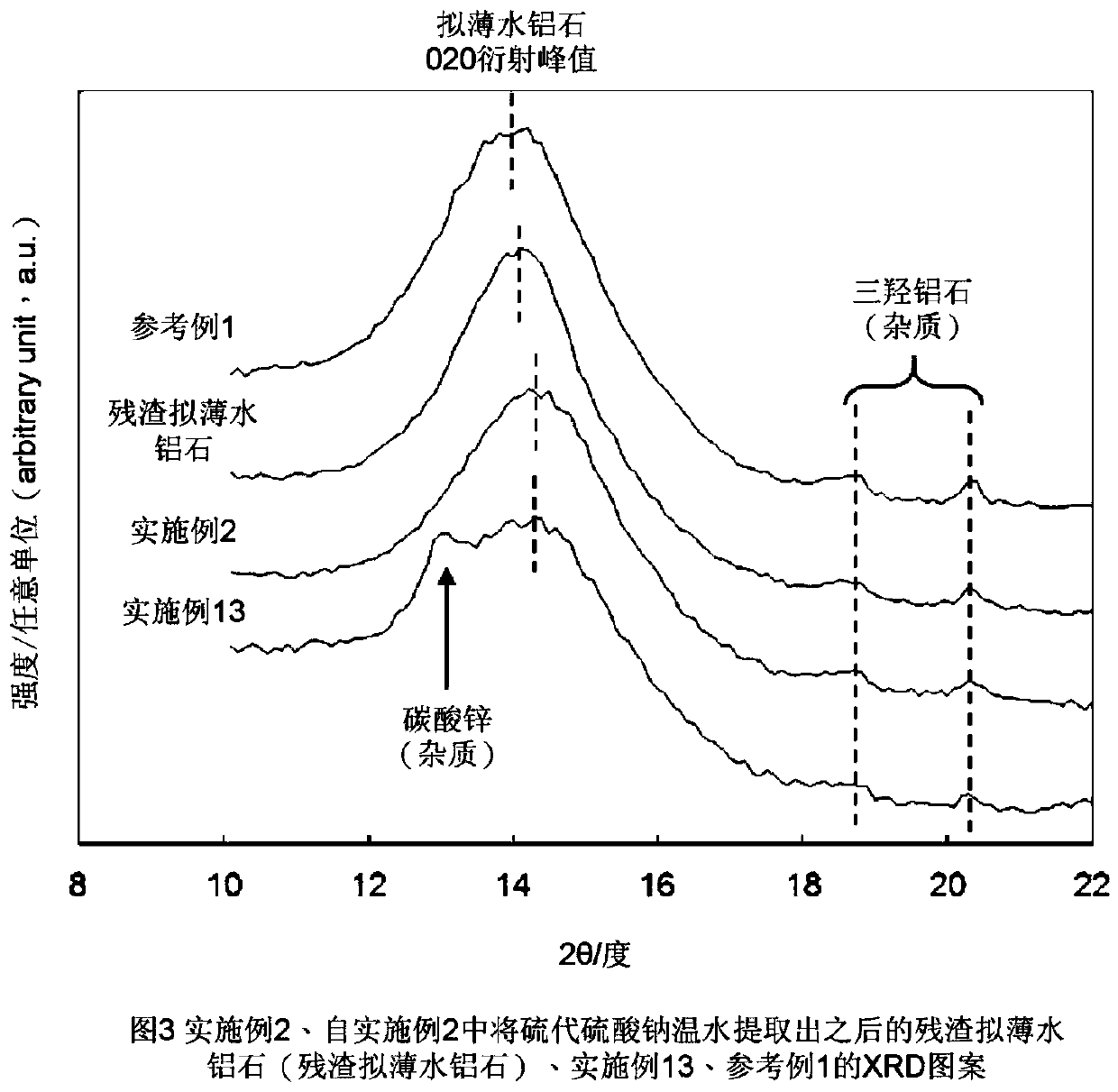

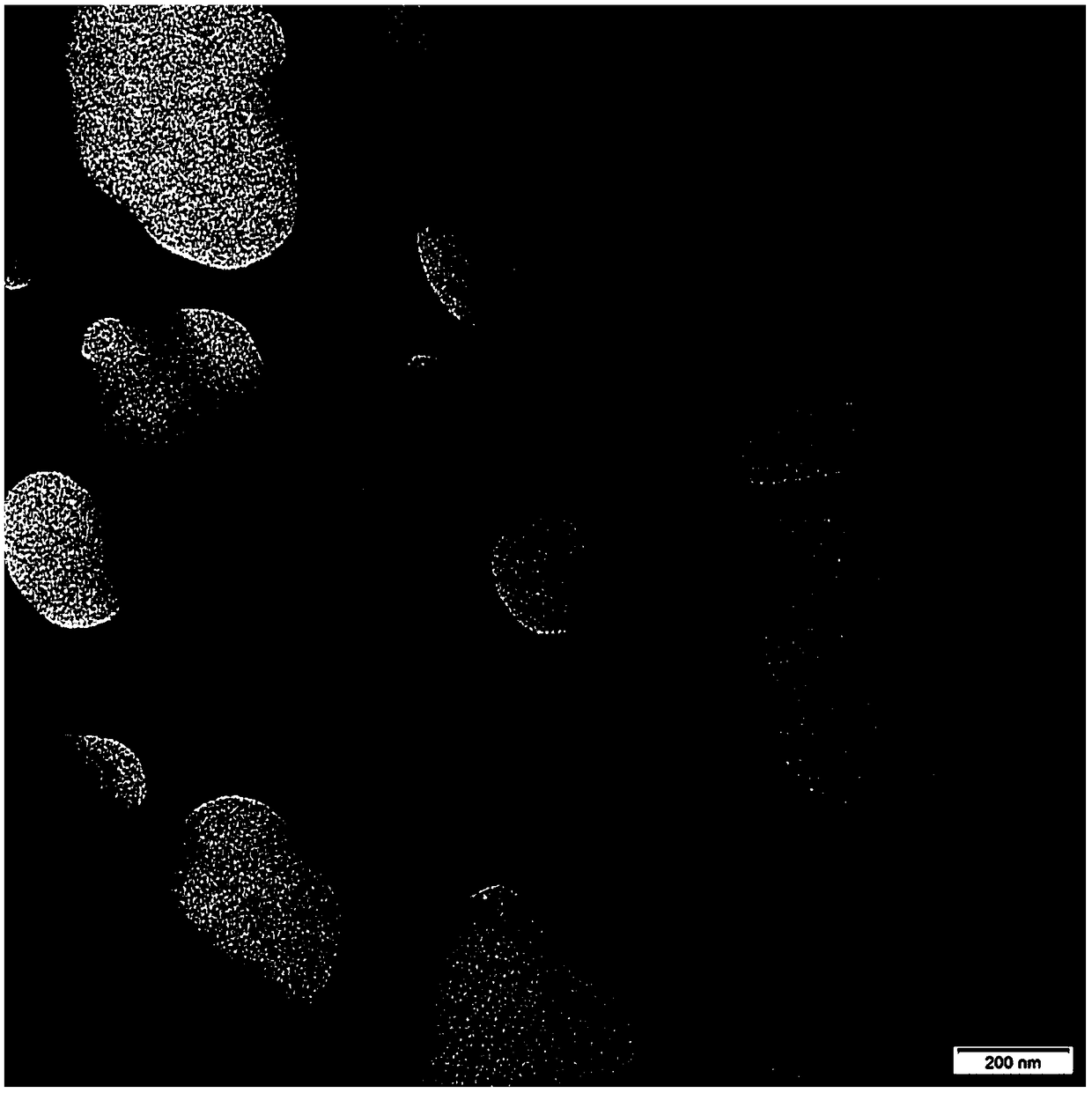

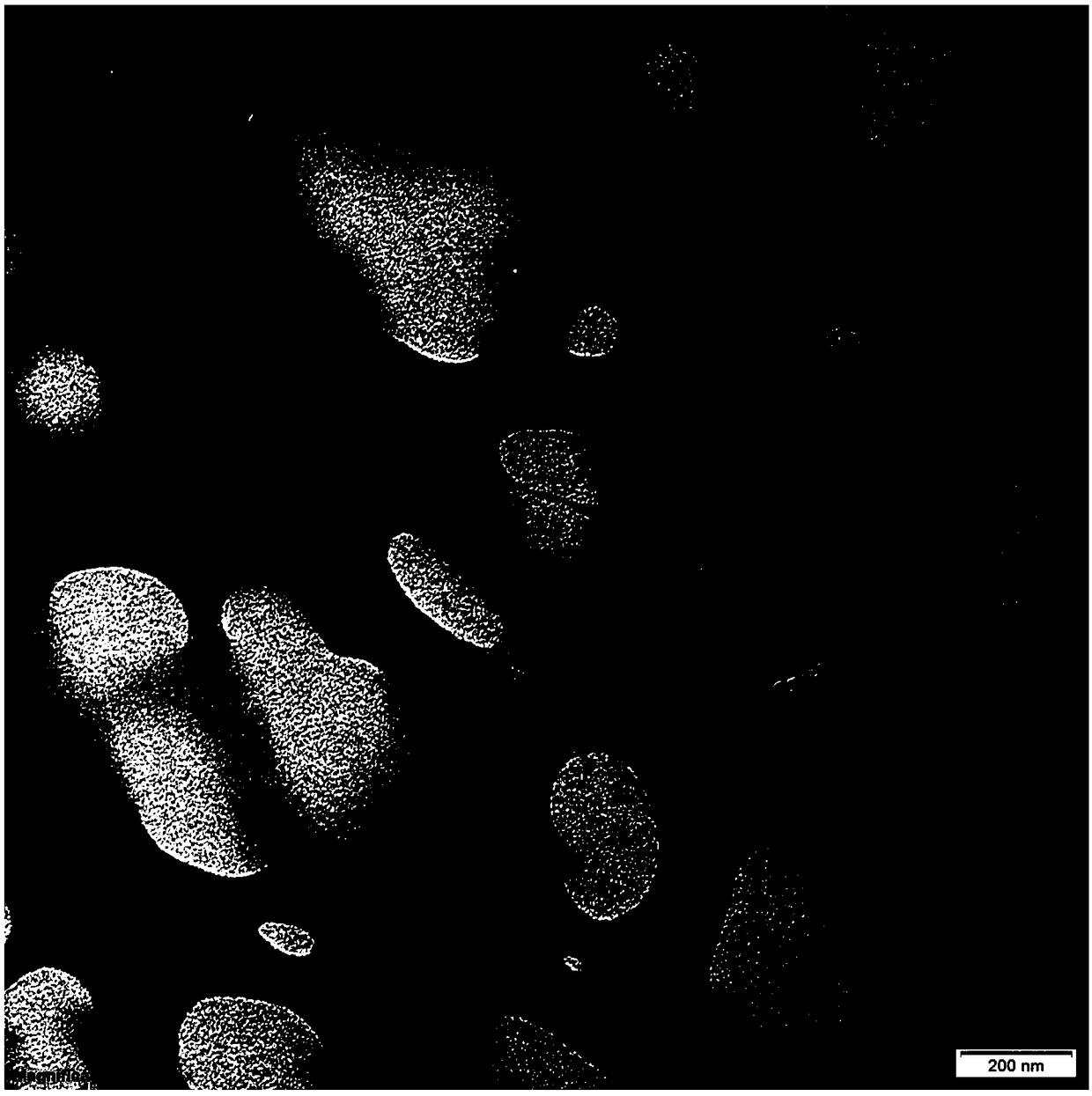

Agent for removing halogen gas, method for producing same, method for removing halogen gas with use of same, and system for removing halogen gas

ActiveCN110267738AEfficient removalGood removal effectGas treatmentOther chemical processesAlkaline earth metalMetalloid

Provided are: an agent for removing a halogen gas such as chlorine in a waste gas by means of reduction; a method for producing this agent; a method for removing a halogen gas with use of this agent; and a system for removing a halogen gas. An agent for removing a halogen gas, which contains at least pseudo-boehmite that serves as a host material and a sulfur-containing reducing agent that serves as a guest material. It is preferable that 1-8% by weight of the reducing agent in terms of elemental sulfur is contained based on the total amount of the pseudo-boehmite and the sulfur-containing reducing agent. It is also preferable that at least one inorganic compound selected from among oxides, carbonate salts and hydrocarbon salts of alkaline earth metal elements, transition metal elements and zinc group elements is additionally contained as a third component.

Owner:CLARIANT CATALYSTS JAPAN

Preparation method and product of calcium oxide desiccant

ActiveCN108905949AInhibit swellingHigh activityGas treatmentOther chemical processesGlass fiberCalcium hydroxide

The invention relates to a preparation method and a product of a calcium oxide desiccant, the preparation method comprises stirring raw materials for mixing to obtain powder, granulating, forming, drying and roasting; the step of stirring the raw materials for mixing to obtain the powder includes: adding calcium carbonate and / or calcium hydroxide, alumina, lignin and glass fiber into a powder mixer for stirring for mixing to obtain the powder, and adding a carboxymethyl cellulose solution prepared from the carboxymethyl cellulose and water into the powder mixer for continuously stirring. By optimizing the composition and proportion of the raw materials, the calcium oxide desiccant form a three-dimensional network structure, has excellent activity, water absorption ability and water fixation ability, and can fully meet the needs of long-term and efficient drying of a camera lens.

Owner:HANGZHOU HOMESONG PACKGING MATERIAL

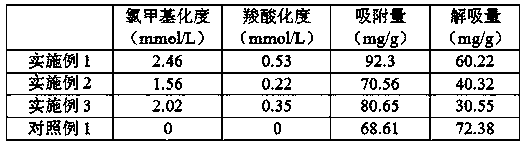

Nonpolar macroporous adsorption resin carboxylation modification method for glycyrrhizic acid adsorption

The invention discloses a nonpolar macroporous adsorption resin carboxylation modification method for glycyrrhizic acid adsorption. Macroporous adsorption resin modification mainly comprises two steps, namely, chloromethylation reactions are implemented on a nonpolar macroporous resin through an ultrasonic catalysis reaction firstly, and then the reaction activity of the macroporous adsorption resin can be improved; secondly, the resin is reacted with a carboxylic acid functional monomer, and then a carboxylation modification macroporous adsorption resin can be prepared. Through the ultrasoniccatalysis reaction, under the action of a chloromethylation reagent, the macroporous adsorption resin of a high carboxylation degree can be prepared, and adsorption capacity tests on glycyrrhizic acid with the modified macroporous adsorption resin show that the adsorption capacity of the modified carboxylation macroporous adsorption resin upon the glycyrrhizic acid is increased when being compared with that of an unmodified macroporous adsorption resin.

Owner:NINGXIA PAGODA CHEM CENT LAB CO LTD

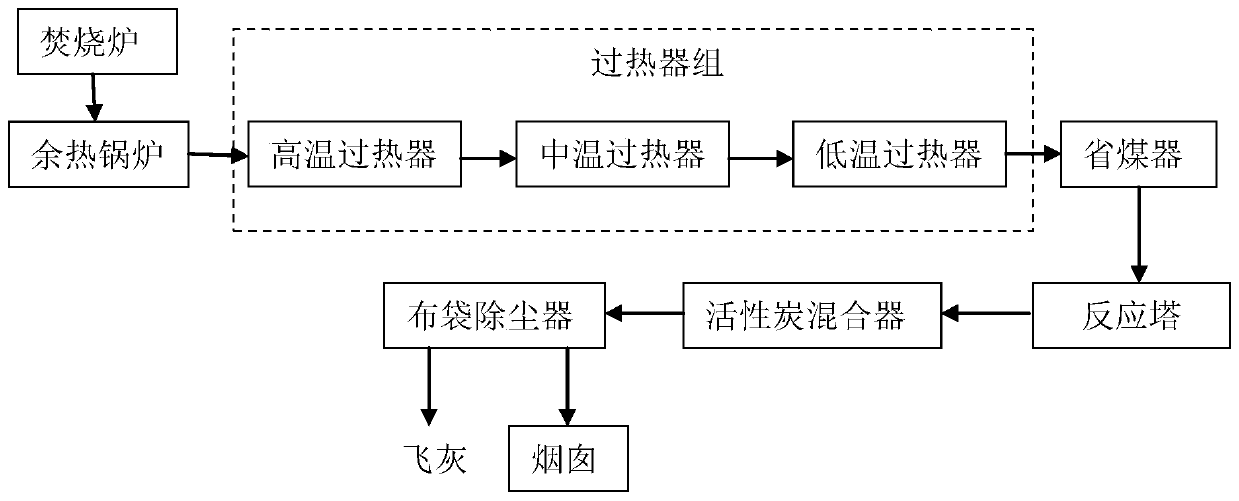

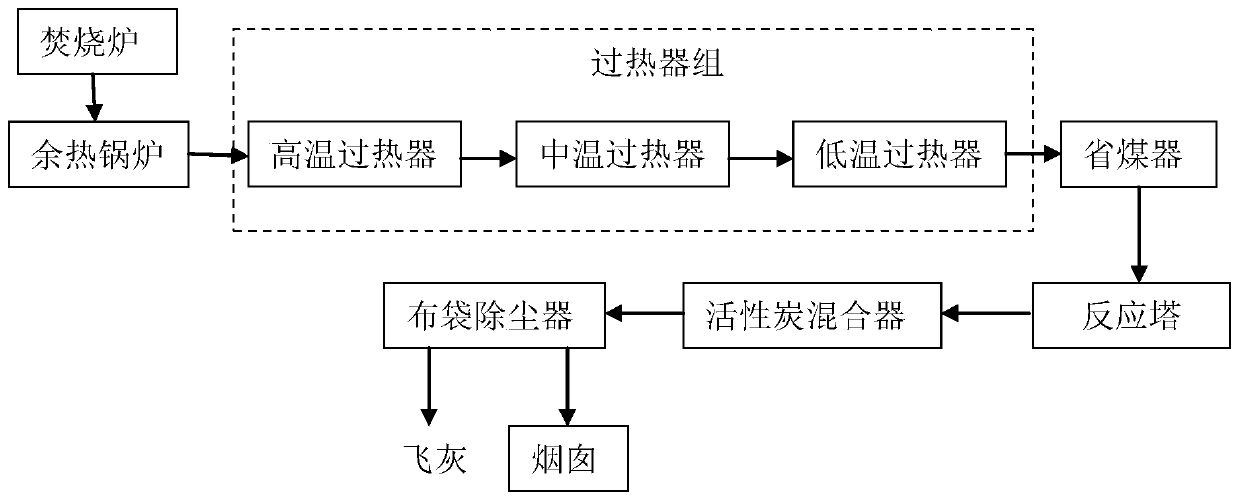

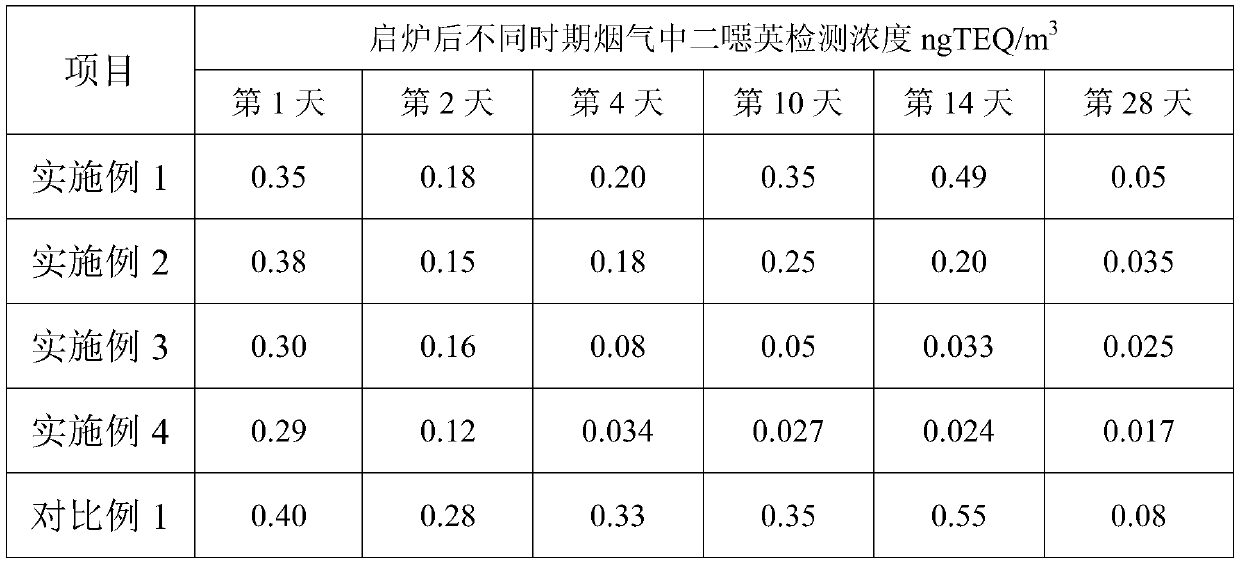

Waste incineration fume treatment method for controlling dioxin memory effect

InactiveCN111121063AGood effectExtended service lifeGas treatmentDispersed particle filtrationActivated carbonHeating efficiency

The invention discloses a waste incineration fume treatment method for controlling the dioxin memory effect. The waste incineration fume treatment method comprises the steps that fly ash and other sediments with the dioxin memory effect in a device and a pipeline are removed before an incinerator is started, activated carbon is pre-sprayed into a bag-type dust collector so that a lot of dioxin generated in the incinerator starting and incineration processes can be effectively adsorbed in time, and moreover, the severe dioxin memory effect caused when the bag-type dust collector adsorbs a massive amount of dioxin because of the device itself, aging and the like in the long-time using process can be controlled. By means of the method, it can be achieved that the discharging concentration ofthe dioxin can meet the discharging standards the next day when the furnace is started, and starts tending to be stable the fourth day after the furnace is started, and the environment-friendly standard requirements are met. The method can effectively control the dioxin memory effect, the heat efficiency is high, energy conservation and environment protection are achieved, the method is simple andfeasible, and the operation is convenient.

Owner:HANLANLVDIAN SOLID WASTE TREATMENT (FOSHAN) CO LTD 2ND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com