Static flotation column suitable for coarse particle recycling

A technology of coarse particles and flotation columns, applied in flotation, solid separation, etc., can solve the problems of not meeting the requirements of coarse particle slime recovery, unstable operation of flotation columns, small processing capacity, etc., and achieve a mild flow field environment , Simple structure, strong processing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

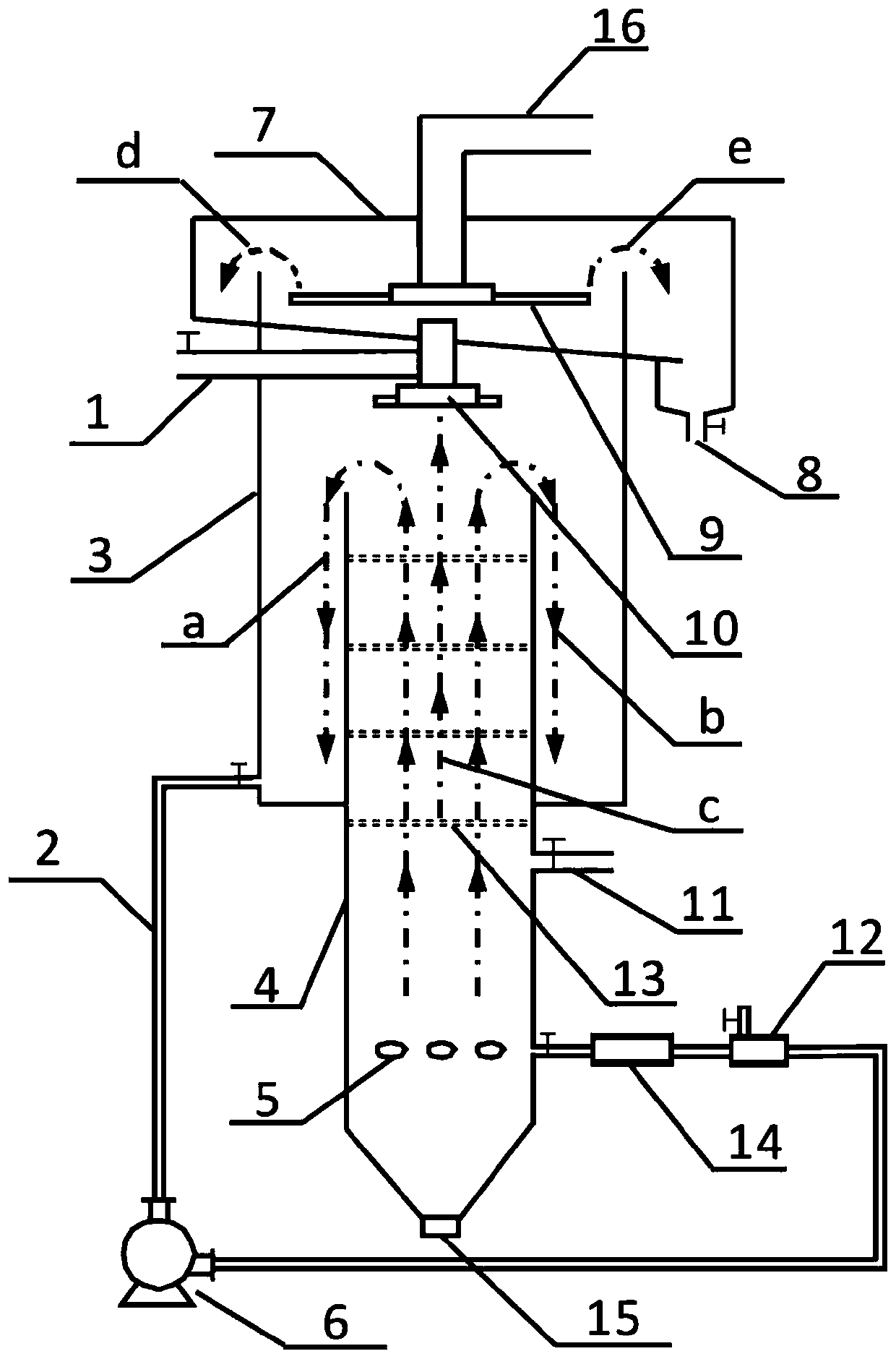

[0029] A specific embodiment of the present invention discloses a static flotation column suitable for coarse particle recovery, such as figure 1 As shown, including the first cylinder 3 and the second cylinder 4, the first cylinder 3 and the second cylinder 4 are barrel-shaped structures, and the second cylinder 4 is partially nested in the first cylinder 3; A feed distributor 10 is provided in the space from the top opening of the second cylinder 4 to the top opening of the first cylinder 3, and the feed distributor 10 is connected with the feed pipe 1; The water distribution pipe 9; the upper outer circumference of the first cylinder 3 is provided with an overflow tank 7; the bottom of the first cylinder 3 and the bottom of the second cylinder 4 are connected by a guide tube 2 to form a fluid circulation pipeline.

[0030] In this embodiment, the second cylinder 4 is partly nested in the first cylinder 3. The specific nesting is: the upper part of the second cylinder 4 pene...

Embodiment 2

[0038] A specific embodiment of the present invention discloses a flotation method suitable for coarse particle recovery, specifically utilizing the static flotation column suitable for coarse particle recovery in Embodiment 1 to carry out flotation, including the following steps:

[0039] Step 1: inject water into the first column 3 and the second column 4 . Specifically, before starting the coal slime flotation, close the first diversion port and the bottom flow pipe / discharge port 15, open the water injection pipe 11 switch, start the water pump, and fill the second cylinder 4 with clear water, and the second cylinder 4 After the middle is filled with water, the water overflows and flows into the second column 4, and 1 / 5 to 1 / 3 volume of clear water is injected into the first column 3, preferably 1 / 4 volume of clear water is injected into the first column 3, and the water injection Complete, close the water injection pipe 11.

[0040] Step 2: Turn on the circulation pump 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com