Agent for removing halogen gas, method for producing same, method for removing halogen gas with use of same, and system for removing halogen gas

一种卤素气体、制造方法的技术,应用在分离方法、气体处理、化学仪器和方法等方向,能够解决未能满足等问题,达到降低管柱更换频率、高速处理速度、防止漏出的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

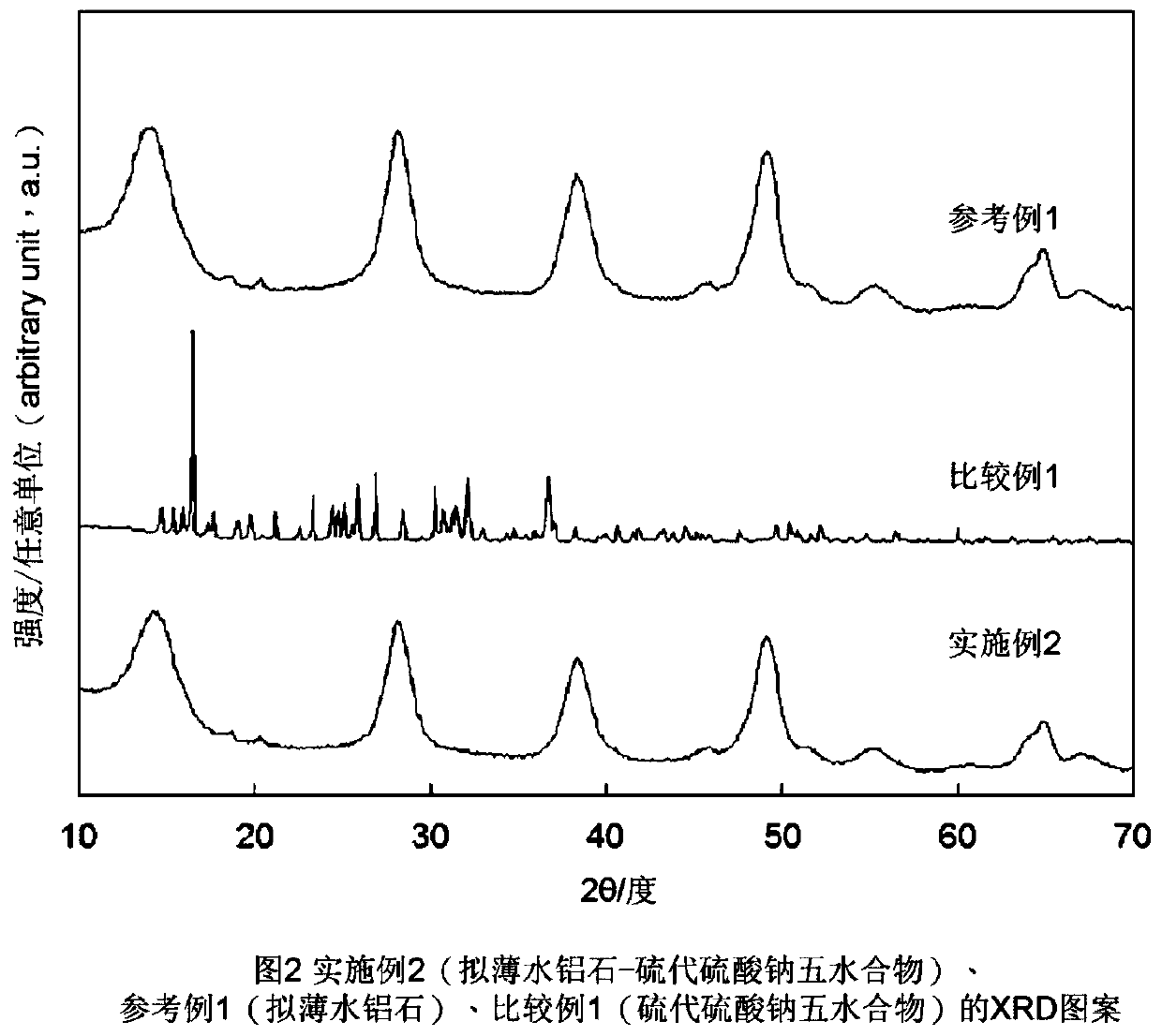

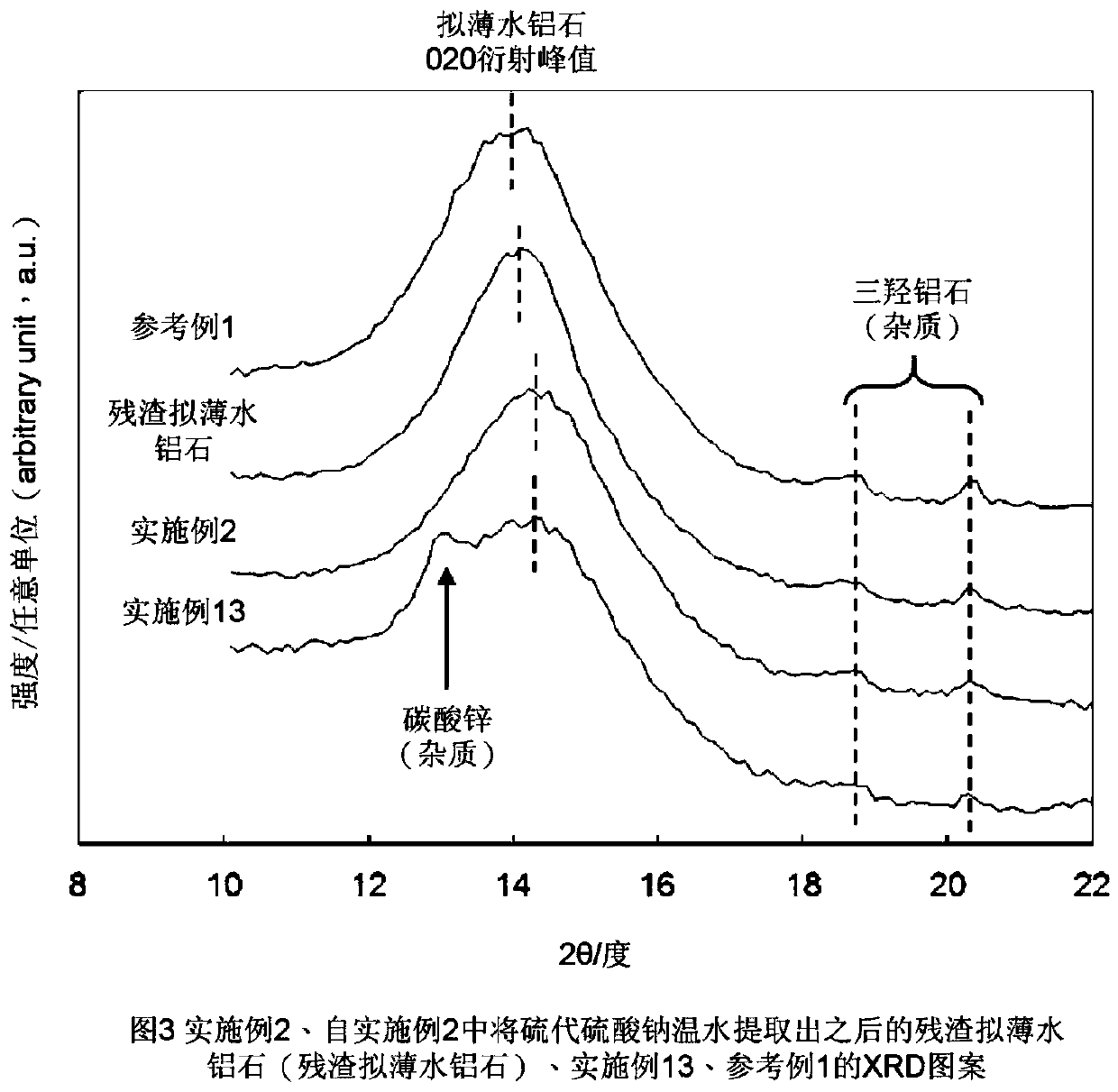

[0125] Remover samples were prepared as follows. The pseudo-boehmite powder and the sodium thiosulfate pentahydrate powder were measured so that the pseudo-boehmite was 90% by weight and the sodium thiosulfate pentahydrate was 10% by weight. ) model 18) was mixed while adding water to obtain a kneaded cake (cake). Using a disk granulator (Fuji Paudal Co., Ltd., model F-5), the kneaded cake was made into a granular molded body with a diameter of about 2 mm and a length of about 6 mm. The obtained molded body was dried overnight in an electric dryer kept at 50° C., then placed in a desiccator for more than 1 hour, and cooled to room temperature to obtain a remover sample of Example 1. Table 1 shows the values of sulfur atom content, tap density, and chlorine removal ability.

Embodiment 2

[0127] The removal agent sample of Example 2 with 82% by weight of pseudo-boehmite and 18% by weight of sodium thiosulfate pentahydrate was prepared by the same method and conditions as in Example 1. Table 1 shows the values of sulfur atom content, tap density, and chlorine removal ability.

Embodiment 3

[0129] The removal agent sample of Example 3, which contained 75% by weight of pseudo-boehmite and 25% by weight of sodium thiosulfate pentahydrate, was prepared by the same method and conditions as in Example 1. Table 1 shows the values of sulfur atom content, tap density, and chlorine removal ability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com