Preparation method and product of calcium oxide desiccant

A technology of desiccant and calcium oxide, which is applied in the direction of chemical instruments and methods, separation methods, alkali metal oxides/hydroxides, etc., to achieve excellent activity, enhance connectivity, and avoid clogging of the water spray gun nozzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

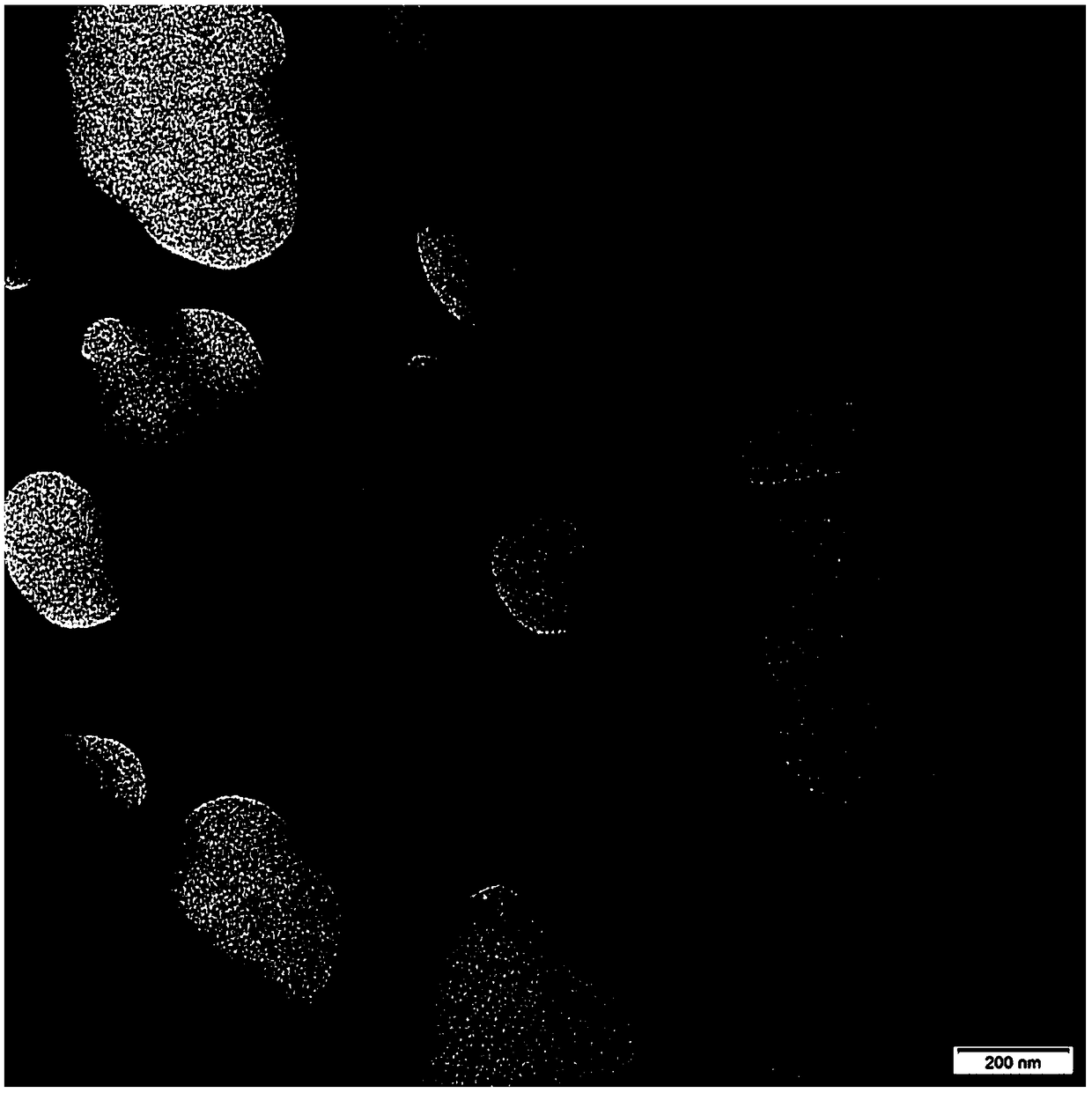

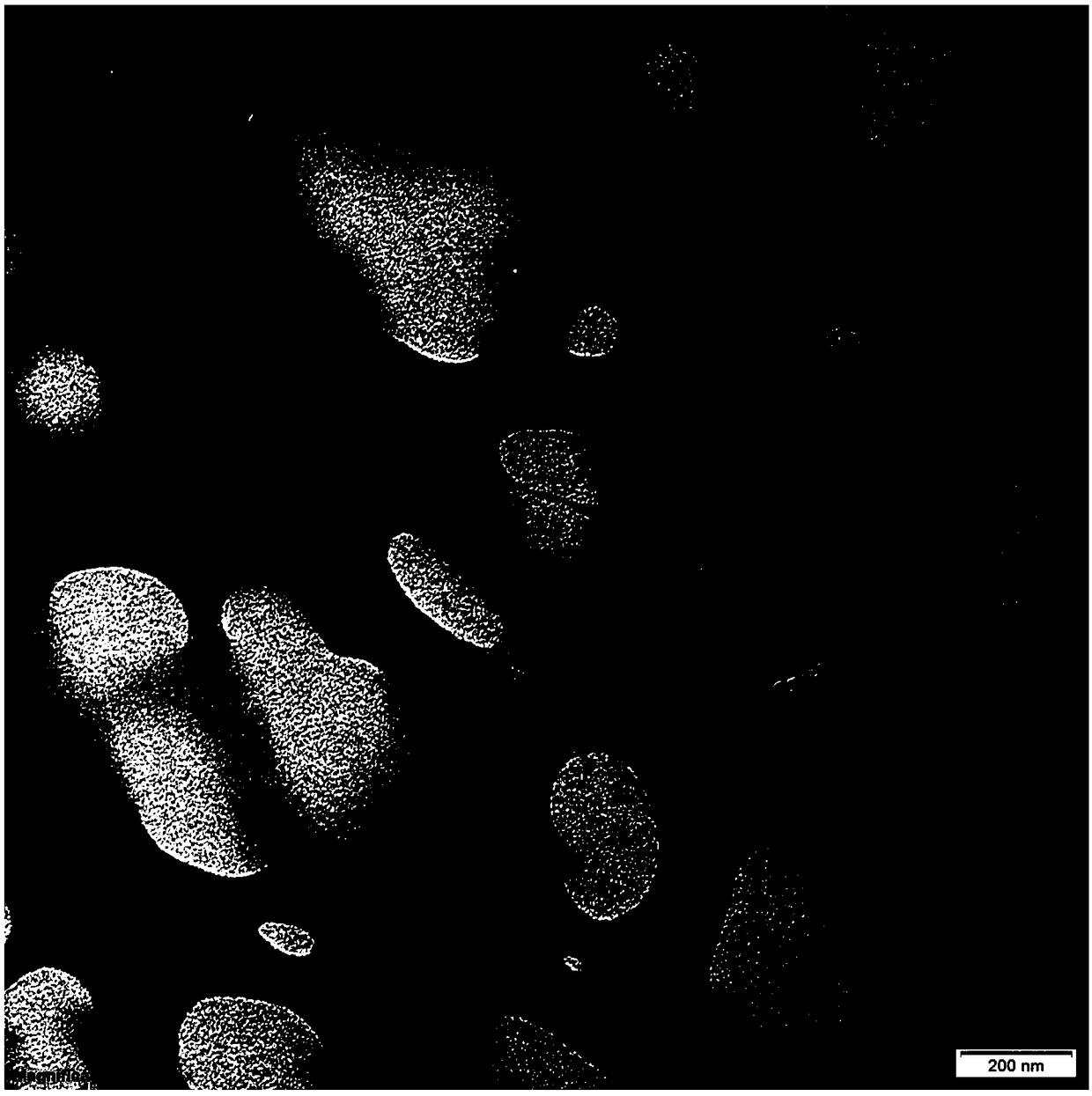

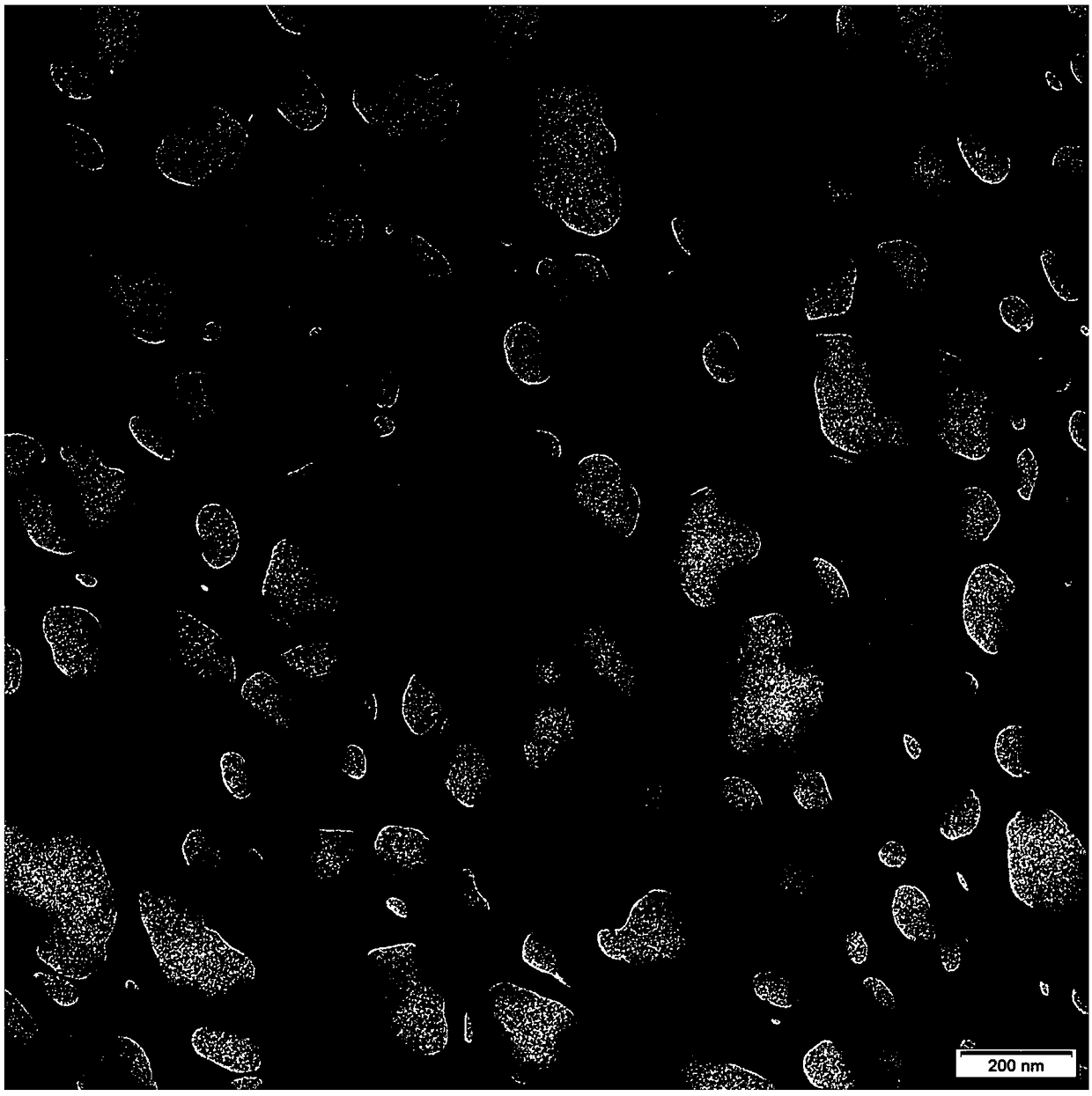

Image

Examples

Embodiment 1

[0046] (1) 66kg calcium hydroxide, 33kg activated alumina, 0.5kg lignin, and 0.5kg glass fiber are added to the powder mixer and stirred for 1h; then 20wt% of 0.5kg carboxymethylcellulose and 2kg water are mixed Add the carboxymethyl cellulose solution into the powder mixer and continue to stir for 0.3h; open the discharge port of the powder mixer to discharge, and keep 1 / 20 of the total amount of raw materials in the powder mixer.

[0047] (2) After the powder mixing is completed, add the mixed powder into the ball pan for granulation.

[0048] (3) After the granulation is completed, put the formed granules into the vibrating sieve for sieving; the vibrating sieve has a three-layer sieving structure, the top sieves out the over-standard particles, which are used as raw materials for powdering, and the middle sieves out The most are semi-finished granules, which are used to add to the polishing machine for polishing, and the sieved bottom layer is the unqualified granules, whi...

Embodiment 2

[0055] (1) 76kg calcium carbonate, 23kg activated alumina, 0.5kg lignin, and 0.5kg glass fiber are added to the powder mixer and stirred for 1 hour, then 20wt% carboxymethyl cellulose and 2kg water are mixed with 0.5kg carboxymethyl cellulose Add the methylcellulose solution into the powder mixer and continue to stir for 0.3h; open the discharge port of the powder mixer to discharge, and keep 1 / 20 of the total amount of raw materials in the powder mixer.

[0056] (2) After the powder mixing is completed, add the mixed powder into the ball pan for granulation.

[0057] (3) After the granulation is completed, put the formed granules into the vibrating sieve for sieving; the vibrating sieve has a three-layer sieving structure, the top sieves out the over-standard particles, which are used as raw materials for powdering, and the middle sieves out The most are semi-finished granules, which are used to add to the polishing machine for polishing, and the sieved bottom layer is the un...

Embodiment 3

[0064] (1) Add 33kg calcium hydroxide, 38kg calcium carbonate, 28kg activated alumina, 0.5kg lignin, and 0.5kg glass fiber into the powder mixer and stir for 1 hour; then prepare 0.5kg carboxymethyl cellulose and 2kg water Add the 20wt% carboxymethyl cellulose solution into the powder mixer and continue to stir for 0.3h; open the discharge port of the powder mixer to discharge, and keep 1 / 20 of the total amount of raw materials in the powder mixer Mix the powder.

[0065] (2) After the powder mixing is completed, add the mixed powder into the ball pan for granulation.

[0066] (3) After the granulation is completed, put the formed granules into the vibrating sieve for sieving; the vibrating sieve has a three-layer sieving structure, the top sieves out the over-standard particles, which are used as raw materials for powdering, and the middle sieves out The most are semi-finished granules, which are used to add to the polishing machine for polishing, and the sieved bottom layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com