Oily sludge treatment method and soil remediation method

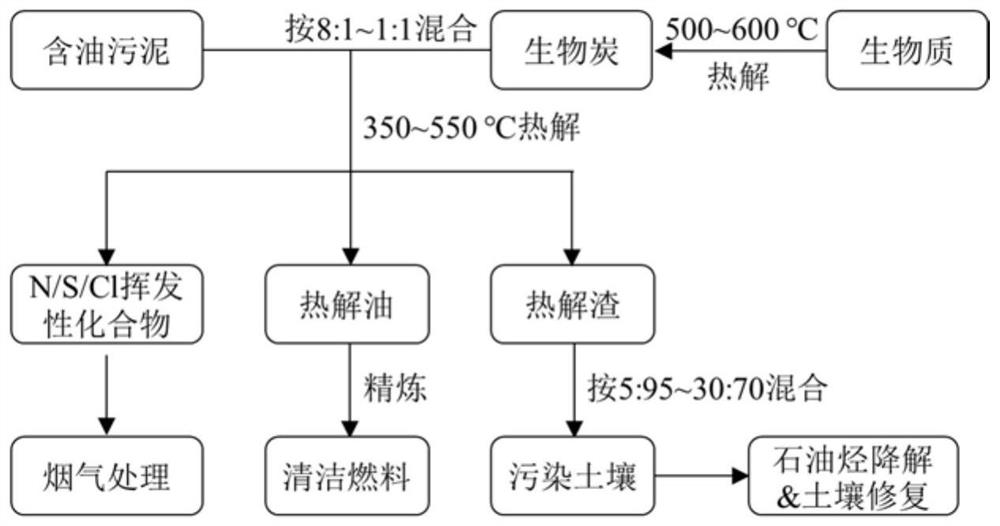

A soil remediation and mass ratio technology, which is applied in the restoration of polluted soil, pyrolysis treatment of sludge, petroleum industry, etc., can solve the problems of difficult separation of catalysts, consumption, occupying a lot of energy or landfill storage capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the objectives, technical solutions and advantages of the present invention more clearly understood, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

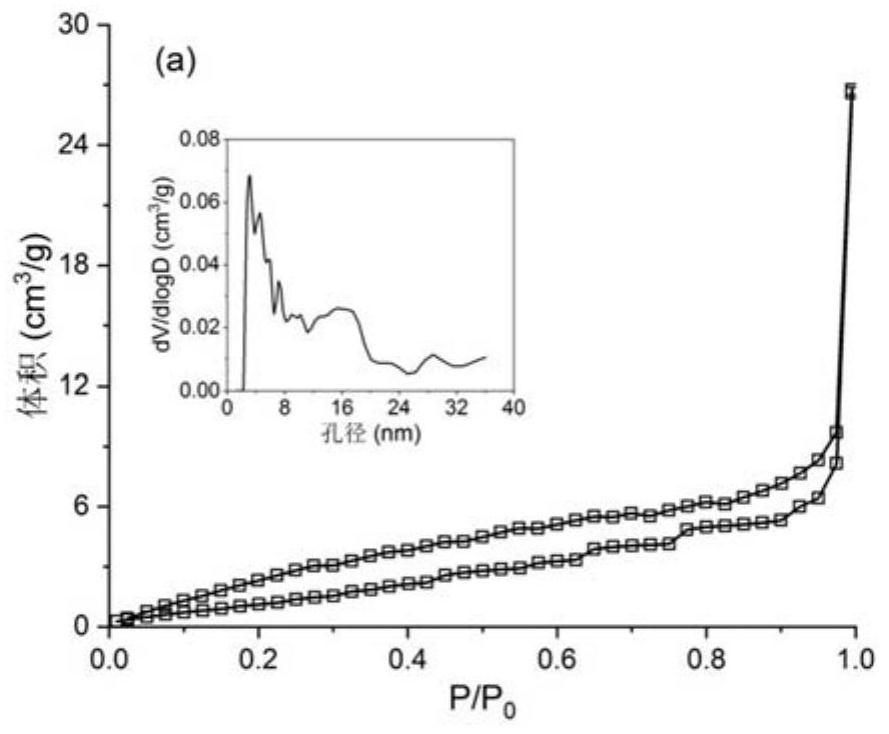

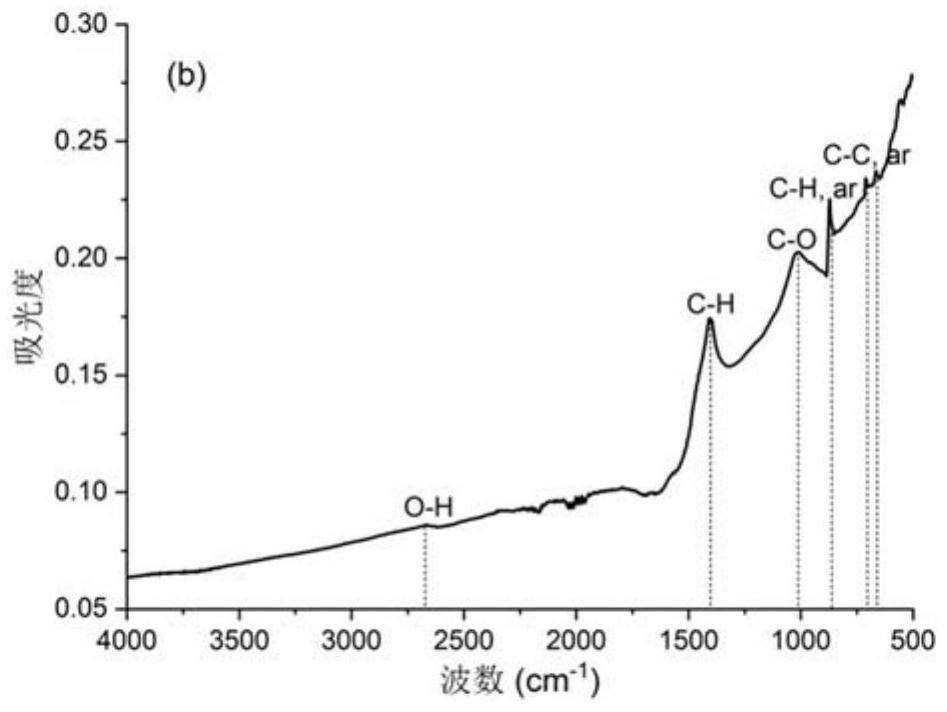

[0024] Oily sludge pyrolysis technology can separate oily sludge into valuable petroleum resources and treatment residues, and produce less secondary pollutants. For example, the invention patents CN 108675589 A and CN 108675590 A describe that the pyrolysis technology is beneficial to solve the problem of difficult oilfield sludge treatment. However, for oily sludge rich in heavy components that are refractory to degradation and high in N / S / Cl, heavy metals and other harmful elements, conventional pyrolysis still has a pyrolysis process that releases a large amount of N / S / Cl-containing volatile pollutants. Such problems as incomplete removal of petroleum hydrocarbons, high energy consumption, and unc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com