Waste incineration fume treatment method for controlling dioxin memory effect

A technology for waste incineration and flue gas treatment, which is applied in the direction of combustion methods, gas treatment, and combustion product treatment. It can solve the problems of increasing the difficulty of dioxin control, achieve improved thermal efficiency, reduce exhaust gas emissions, and achieve remarkable results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

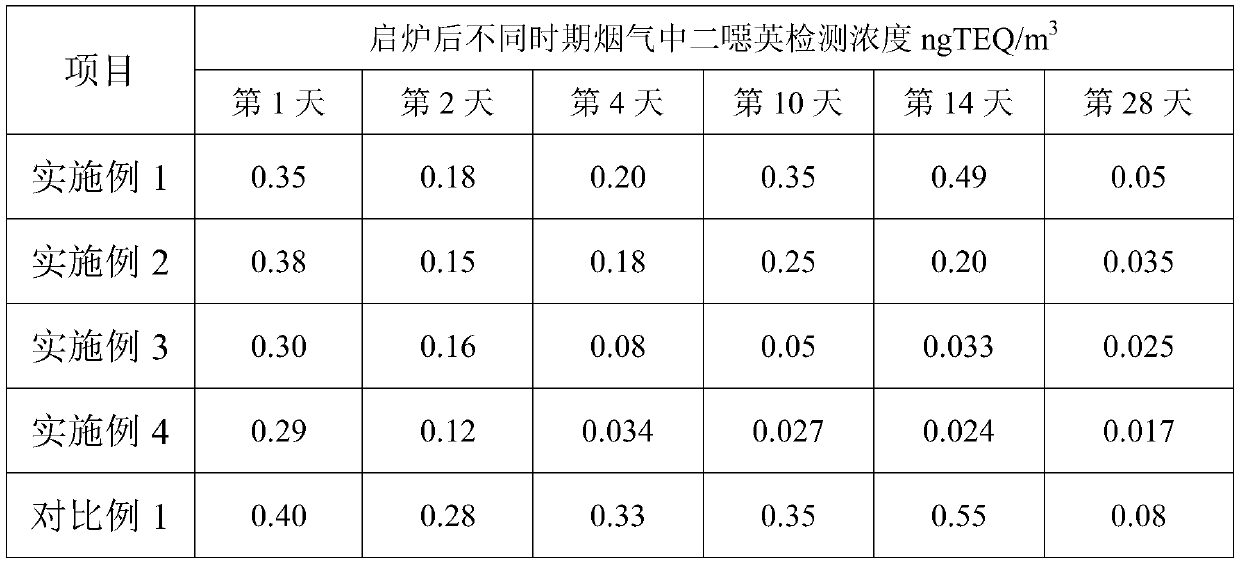

Embodiment 1

[0034] A waste incineration flue gas treatment method for controlling the memory effect of dioxins, comprising:

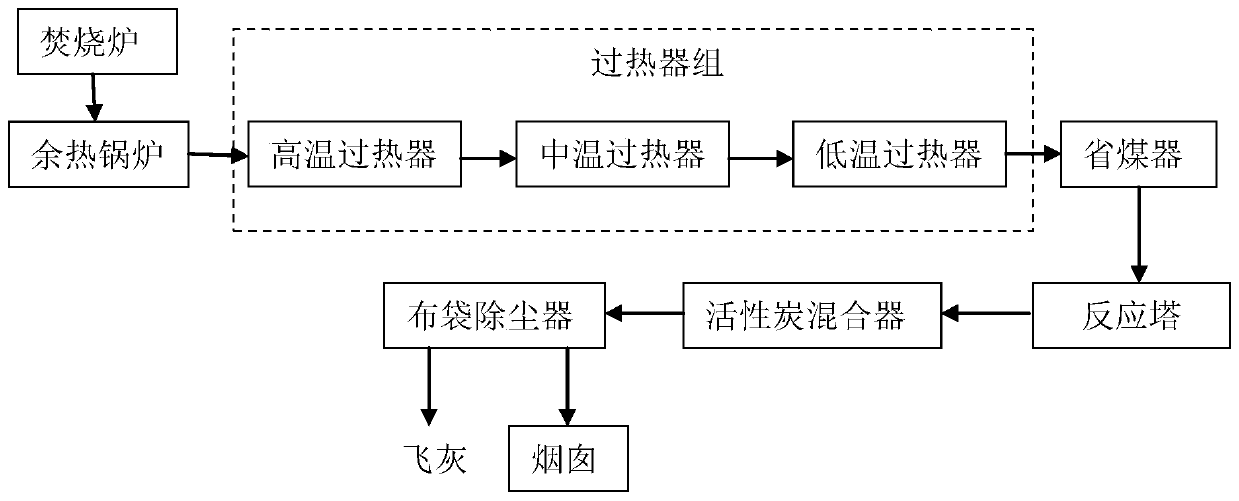

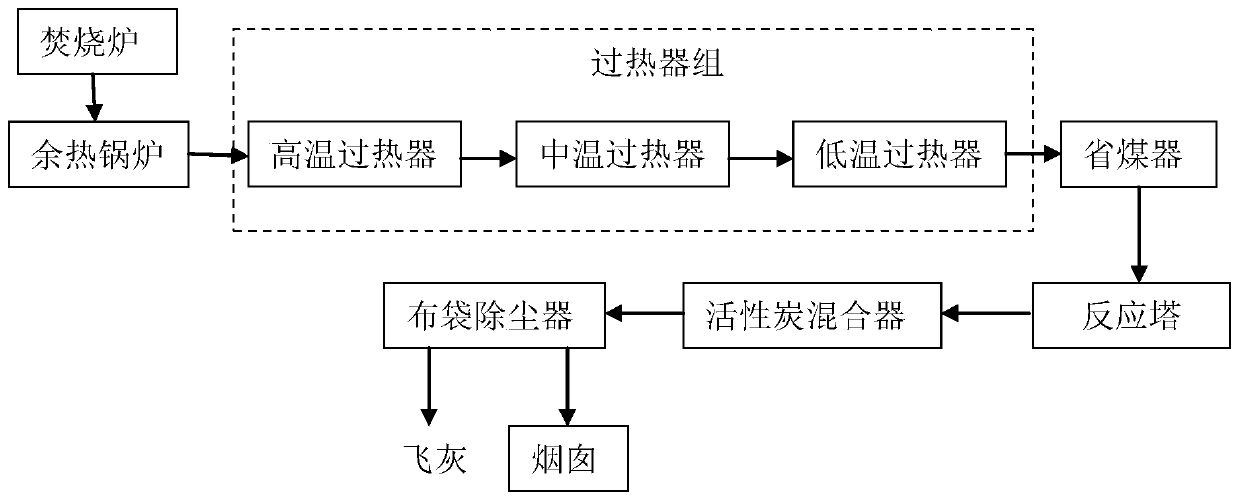

[0035] S1: Start the incinerator, and process the flue gas obtained after garbage incineration through the waste heat boiler, superheater group and economizer in order to recover the heat of the flue gas for recycling and reduce the temperature of the flue gas;

[0036] S2: Pass the flue gas obtained in S1 into the reaction tower and activated carbon mixer for flue gas treatment in sequence, and then pass it into the bag filter; 2 hours before starting the incinerator, pre-spray activated carbon on the inner surface of the bag filter with a spray volume of 80mg / m 3 ;

[0037] S3: The miscellaneous particles and fly ash in the bag filter are introduced into the ash storage, and the flue gas obtained in S2 is introduced into the chimney and discharged into the atmosphere.

Embodiment 2

[0039] A waste incineration flue gas treatment method for controlling the memory effect of dioxins, comprising:

[0040]S1: Start the incinerator, and process the flue gas obtained after garbage incineration through the waste heat boiler, superheater group and economizer in order to recover the heat of the flue gas for recycling and reduce the temperature of the flue gas;

[0041] S2: Pass the flue gas obtained in S1 into the reaction tower and activated carbon mixer for flue gas treatment in turn, and then pass it into the bag filter; 2 hours before starting the incinerator, pre-spray activated carbon on the inner surface of the bag filter with a spray volume of 150mg / m 3 ;

[0042] S3: The miscellaneous particles and fly ash in the bag filter are introduced into the ash storage, and the flue gas obtained in S2 is introduced into the chimney and discharged into the atmosphere.

Embodiment 3

[0044] S1: Pretreatment, including: before starting the incinerator, clean up the superheater group, economizer, reaction tower, bag filter, ash storage and pipelines where the waste incineration flue gas passes through, so as to ensure that the channels on the heating surface are unblocked and the pipelines are clean. No dust and slagging;

[0045] S2: Start the incinerator, and process the flue gas obtained after incinerating waste through the waste heat boiler, superheater group, and economizer in order to recover the heat of the flue gas for recycling and reduce the temperature of the flue gas;

[0046] S3: The flue gas obtained in S2 is passed into the reaction tower and activated carbon mixer for flue gas treatment, and then passed into the bag filter;

[0047] S4: The miscellaneous particles and fly ash in the bag filter are introduced into the ash storage, and the flue gas obtained in S3 is introduced into the chimney and discharged into the atmosphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com