Anti-blocking combined process and system for high treatment efficiency of low-concentration VOC tail gas

A treatment efficiency and combined process technology, applied in the direction of climate sustainability, greenhouse gas reduction, lighting and heating equipment, etc., can solve the problems of environmental protection device parking, corrosion, and affecting production and operation, so as to prevent the regeneration of ammonium salt and reduce Blockage, the effect of increasing the furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

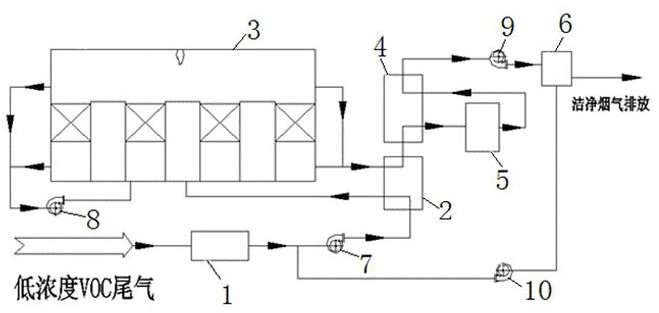

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] A kind of low-concentration VOC tail gas high treatment efficiency anti-clogging combined process of the present invention, it comprises the following steps,

[0029] (1) Collect low-concentration VOC tail gas for pretreatment, so that its concentration meets the incineration treatment of RTO furnace 3 ;

[0030] (2) Preheat the pretreated tail gas to 70°C, and the heat source for tail gas preheating is the hot flue gas in the subsequent process;

[0031] (3) After the tail gas is preheated, it is sent to the RTO furnace for incineration treatment, and the organic matter in it is removed once, and the removal rate is greater than 99%. The flue gas temperature after the RTO furnace incineration treatment is about 120~180°C;

[0032] (4) The high-temperature fan is used to draw back-burning flue gas from the RTO furnace and furnace bottom in propo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com