Method and system for collecting aromatic substances and adding same to wine during fermentation

An aroma substance and fermentation process technology, which is applied in the field of brewing to increase the aroma of wine, can solve the problems of great difference in volatility of aroma substances, low concentration of aroma substances, and difficulty in setting the gas-liquid ratio, so as to improve the absorption efficiency and realize industrialization. The effect of chemical production and flow reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

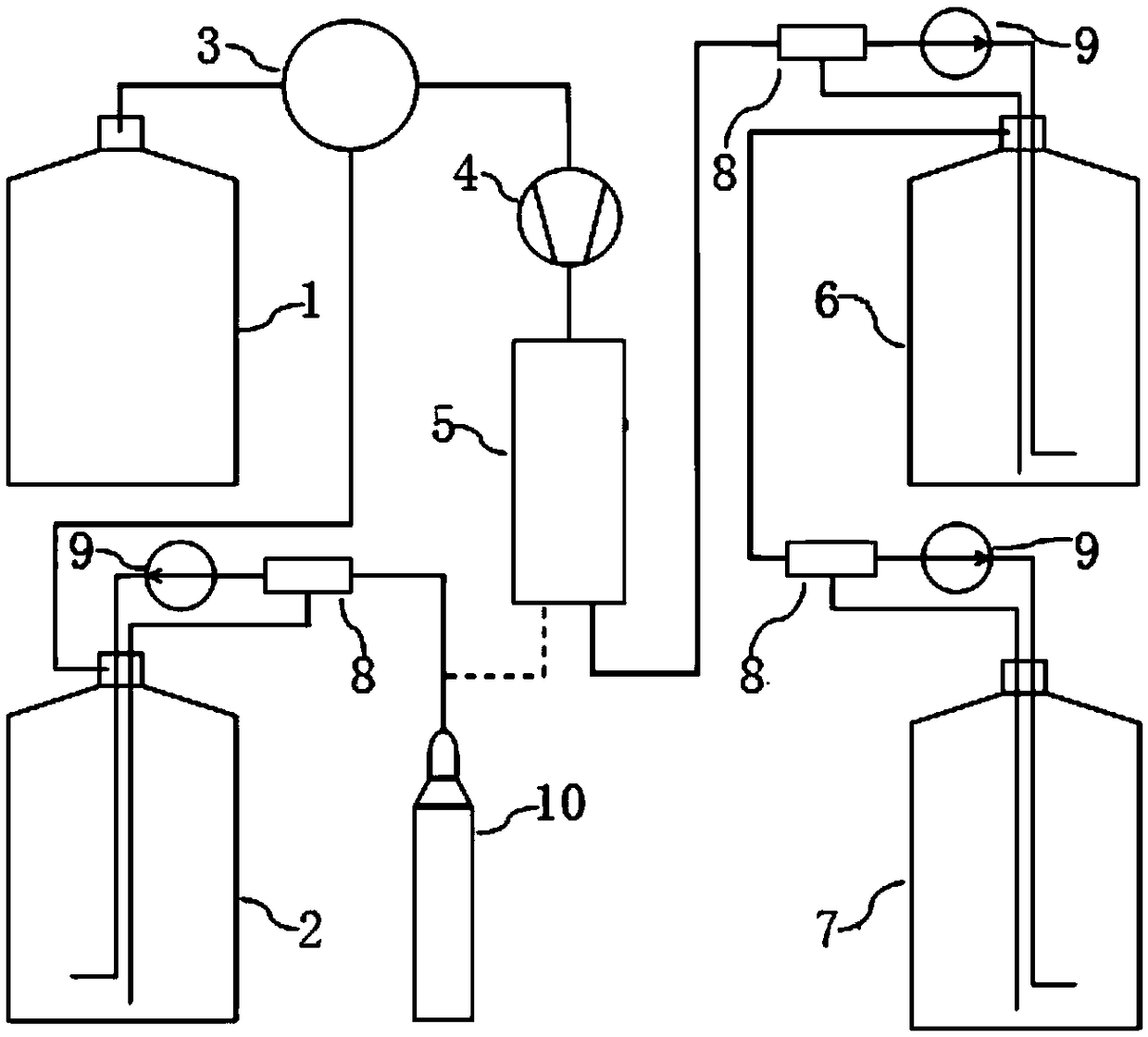

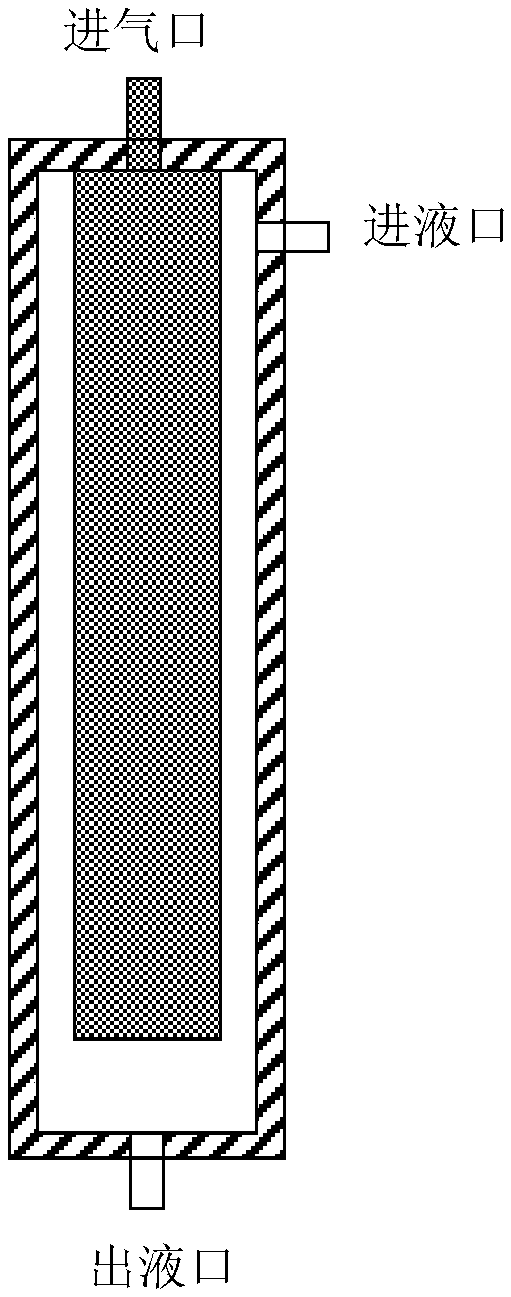

[0036] This embodiment realizes the purpose of the present invention to significantly increase the aroma of wine with the simplest scheme and less brewing amount in the laboratory. The specific plan is as follows: use a stainless steel fermentation tank with a wall thickness greater than 1.5 mm, 65 liters, and a pressure resistance of more than 6 bar as an alcohol fermentation tank. Use 3 aromatic polyamide composite reverse osmosis membrane elements for brackish water with an effective membrane area of 8.4m2 / piece or use other reverse osmosis membrane elements with good separation effect on aroma substances and carbon dioxide. The connection method of one branch in the second section constitutes a membrane separation device. It is also possible to combine a reverse osmosis membrane element and a polyimide nitrogen membrane element to connect the membrane separation device. A 34-liter stainless steel fermenter that can be refrigerated with insulation is used as the absorpti...

Embodiment 2

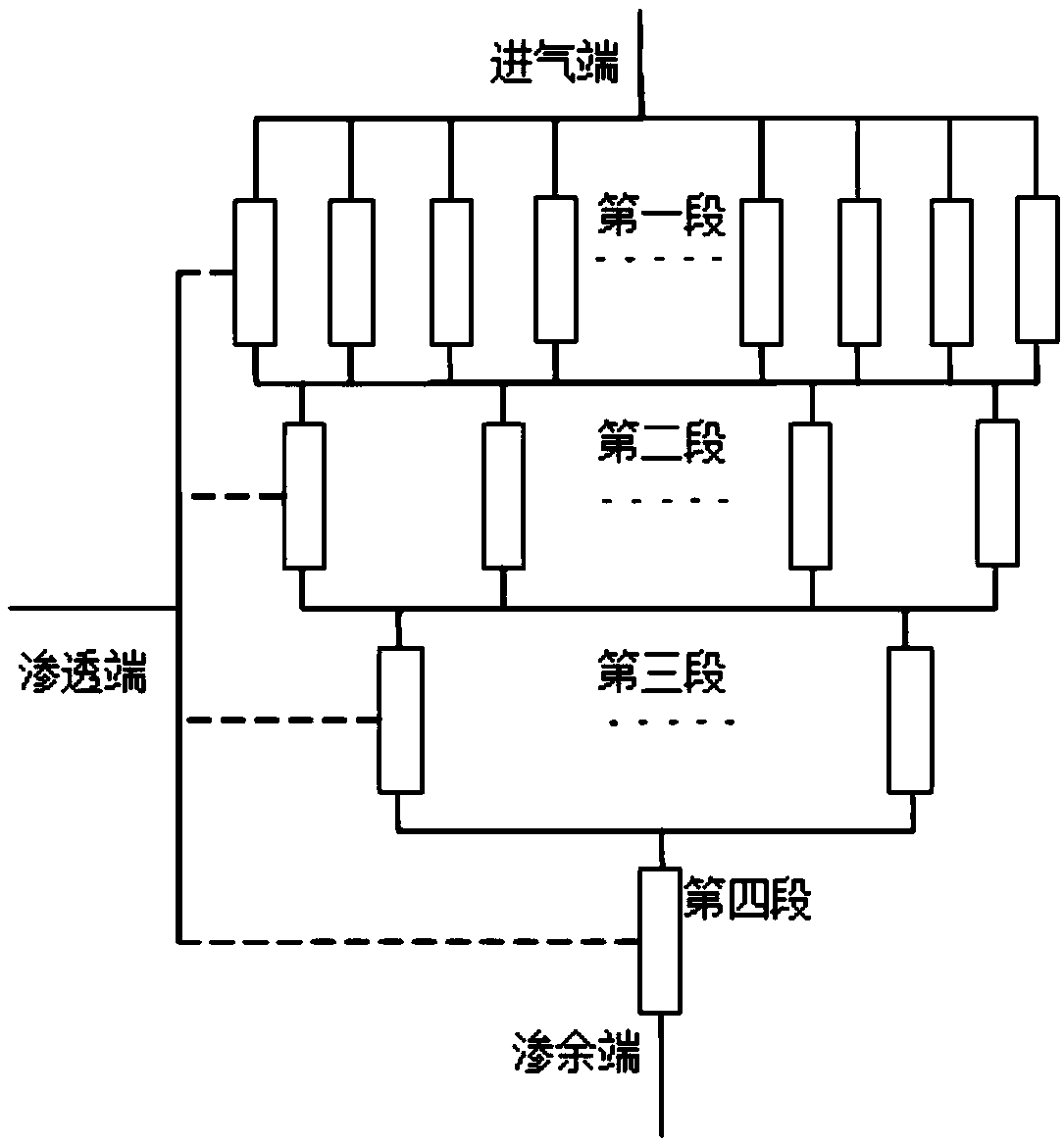

[0041]This embodiment provides a small-scale operating system for carrying out large-scale production experiments and collecting data. The system is made of a 10 cubic meter vertical circulation spray stainless steel fermenter for alcohol fermenters, and a 10 cubic meter vertical circulation Spray stainless steel fermentation tanks for secondary malic acid-lactic acid fermentation tanks and microbubble desorption and extraction tanks. Use 15 pieces of aromatic polyamide composite reverse osmosis membrane elements for brackish water with an effective membrane area of about 35m2 / piece, or use the above-mentioned reverse osmosis membrane that is customized for the separation of fermentation mixed gas and has a better separation effect on aroma substances and carbon dioxide For similar membrane elements, the membrane separation device is composed of 8 pieces in the first section, 4 pieces in the second section, 2 pieces in the third section, and 1 piece in the fourth section. It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com