Multiple-quantum well waveguide butt-coupling method

A docking coupling and multi-quantum well technology, which is applied in the field of multi-quantum well waveguide docking coupling, can solve the problems of difficult precise control of corrosion depth, inconsistent corrosion depth, and low coupling efficiency, so as to avoid insertion loss, improve the quality of docking coupling, and improve The effect of material quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The method of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments of the present invention.

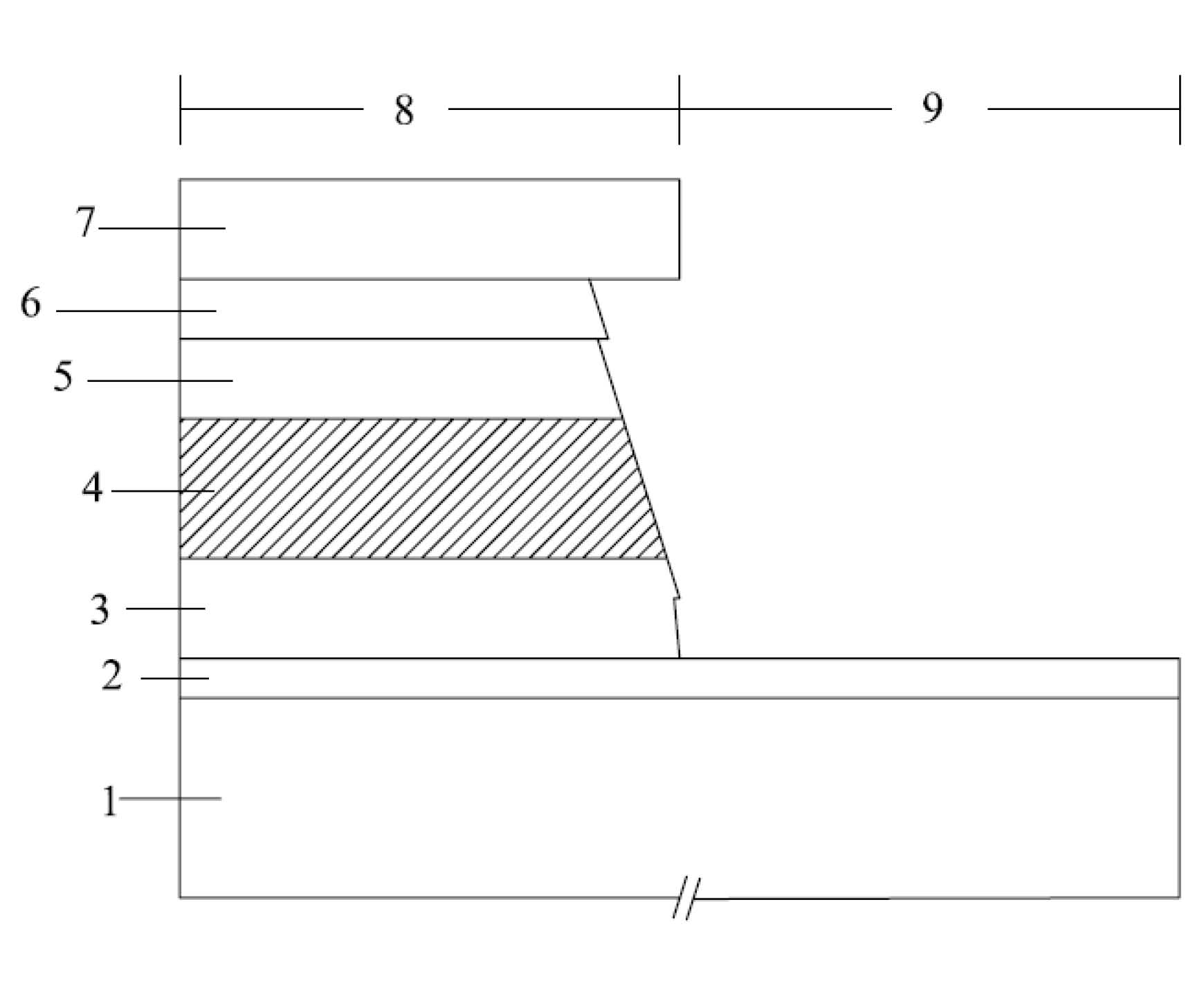

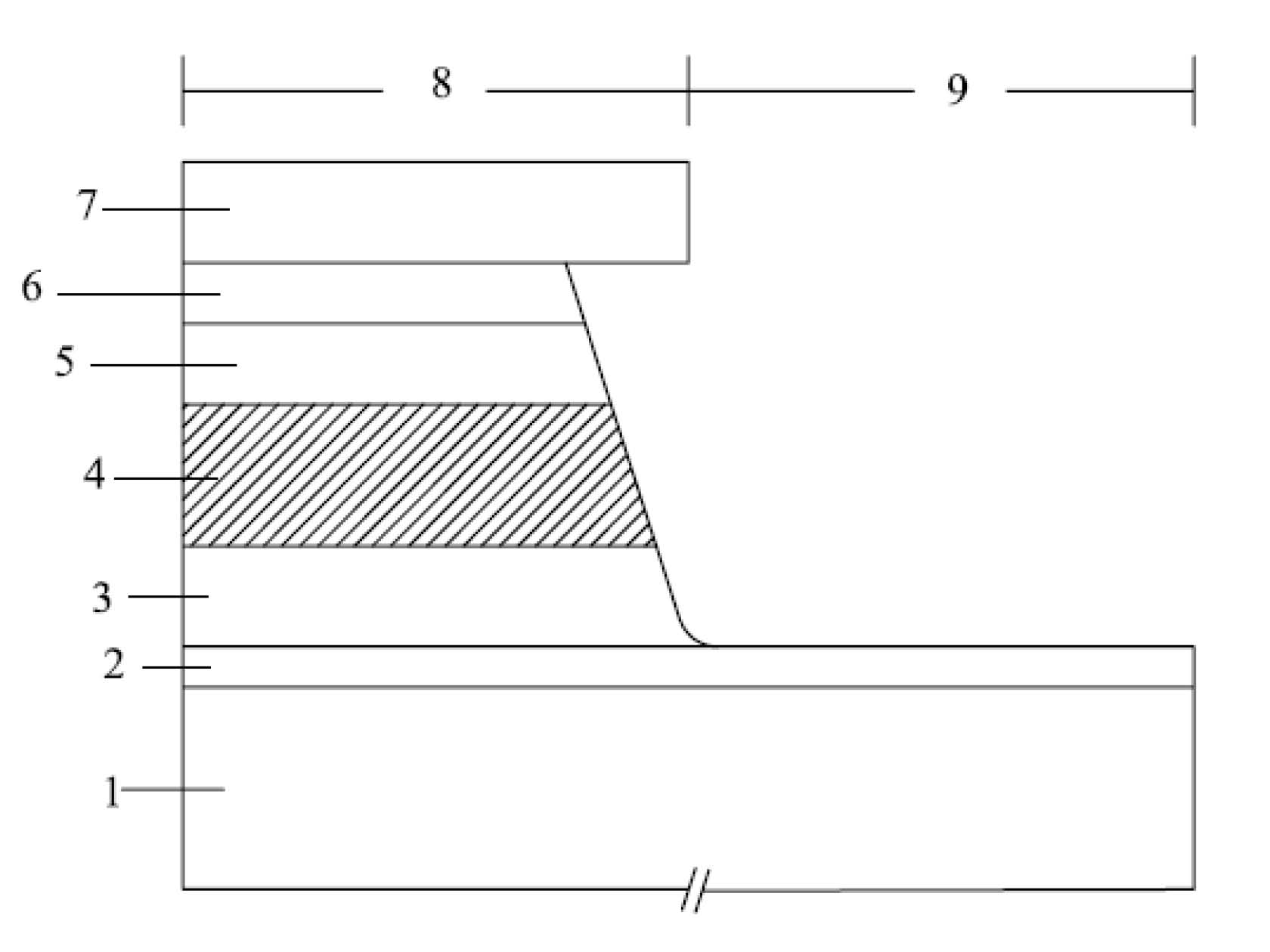

[0045] The main idea of the present invention is to use non-selective corrosion to control the interface corrosion morphology, and use selective corrosion to accurately control the corrosion depth, and use metal organic chemical vapor deposition (MOCVD) high temperature heat treatment method to optimize the interface corrosion morphology, Therefore, the light loss at the docking interface is small, and the process is simple and repeatable.

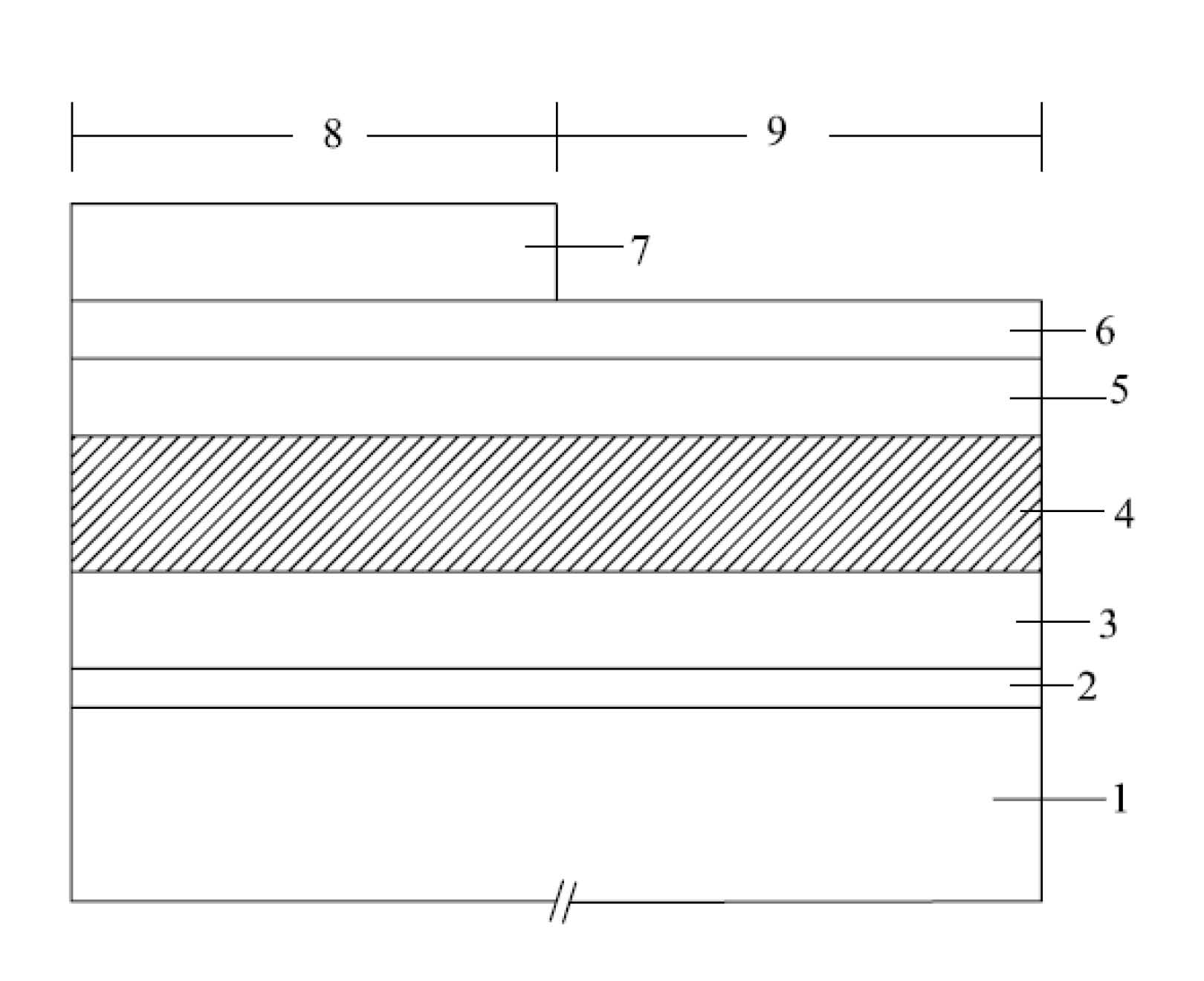

[0046] figure 1 It is a schematic diagram of a single-epitaxial multi-quantum well structure of the present invention, referring to Figure 2 ~ Figure 4 , the multi-quantum well waveguide butt coupling method mainly includes the following steps:

[0047] Step 1: Epitaxially epitaxially first the first multiple quantum well structure on the N-type substrate.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com