Low-pressure adsorption natural gas storage tank

A low-pressure adsorption, natural gas technology, applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, ship construction details, etc., can solve the problems of high operating costs, high pressure, large investment, etc., to achieve uniform adsorption and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

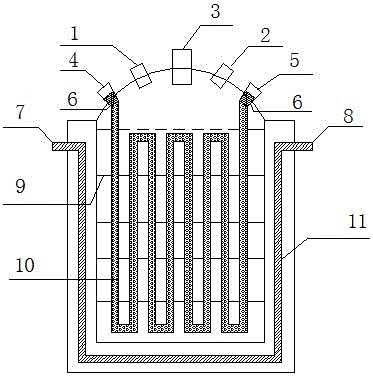

[0018] as attached figure 1 As shown, a low-pressure adsorption natural gas storage tank described in the embodiment of the present invention is composed of a tank body and an external jacket, wherein the tank body is equipped with an air inlet, an air outlet, an activated carbon inlet, Phase change reaction agent inlet, phase change reaction agent outlet, the inside of the tank has activated carbon partition layer, stainless steel coil, the outer jacket is equipped with circulating cooling water pipes, and is equipped with water inlet and water outlet, the The air inlet and outlet are equipped with nano-filter cores of special structure, the stainless steel coil is filled with a phase change reaction agent, and is easy to replace, the outer jacket is sealed and welded to the tank body; the phase change reaction The agent is ammonium hydrate; the material of the nano-filter core is porous titanium, and the aperture of the nano-filter core is 1nm; the activated carbon partition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com