Auxiliary grouting platform and construction method for crossing large karst caves during excavation of existing tunnels

A technology for large-scale karst caves and existing tunnels, applied in tunnels, tunnel linings, and earth-moving drilling and mining, etc., can solve the problems of affecting the logistics and traffic of the lower half-section tunnel, reducing the efficiency of expansion and affecting the excavation of the tunnel, and shortening the construction period. Improve the excavation efficiency and ensure the effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

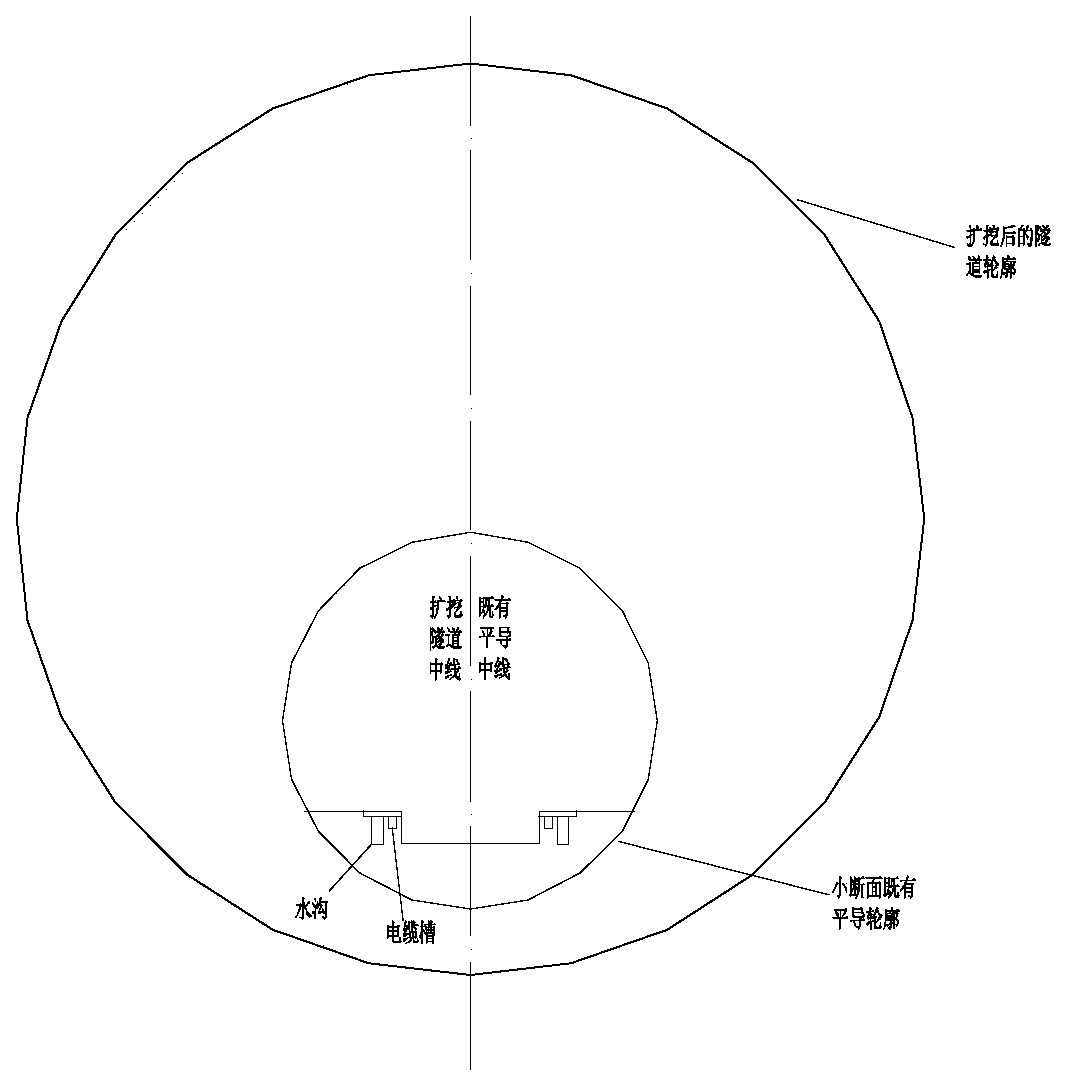

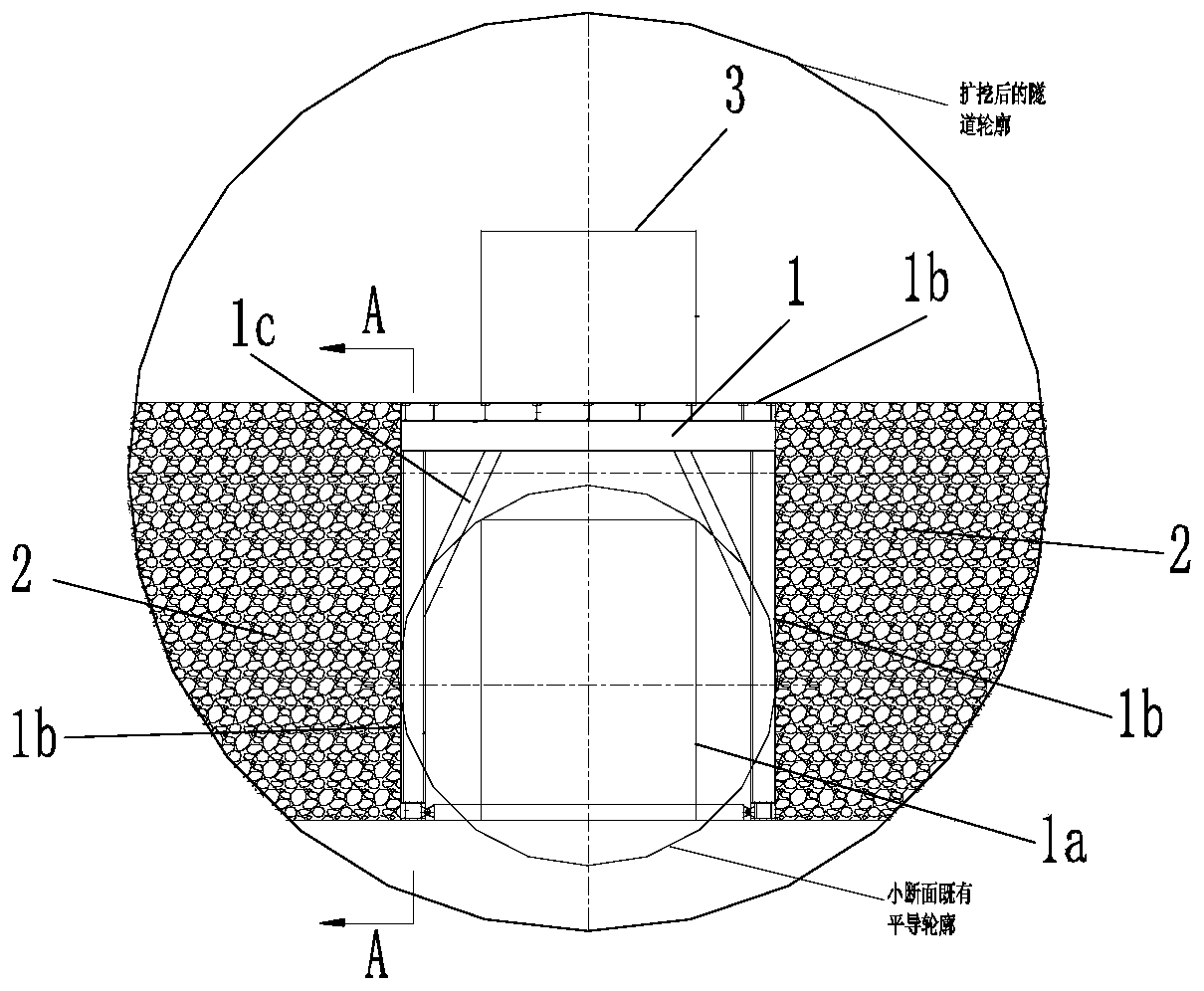

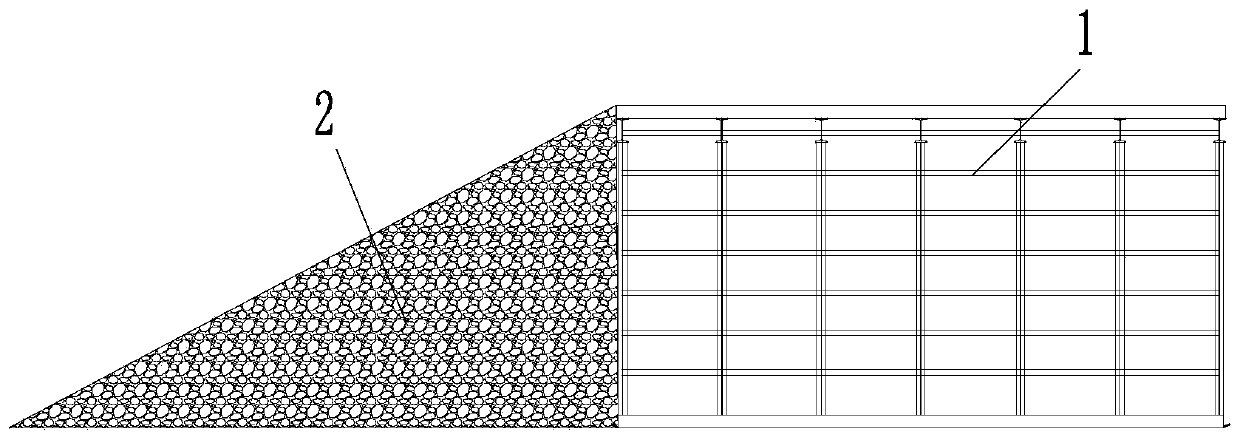

[0021] combine figure 1 — image 3 As shown, an auxiliary grouting platform for passing through a large karst cave during excavation of an existing tunnel is mainly composed of a grouting platform 1 and a temporary ramp 2 for the upper and lower platforms of the drilling rig.

[0022] The grouting platform 1 adopts a steel frame structure, and a material channel 1a passing through the front and back is provided in the middle of the steel frame structure, and steel plates 1b are respectively fixed on the top wall, left side wall, and right side wall of the steel frame structure. Steel plates 1b are laid on the top wall to facilitate the support of the drilling rig 3; steel plates 1b are laid on the left and right side walls to block the tunnel slag from the temporary ramp 2 on the upper and lower platforms of the drilling rig.

[0023] The grouting platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com