Narrow gap automatic welding seam repair method and system

A repair method and repair system technology are applied in the field of narrow gap automatic welding seam repair and systems, which can solve the problems that the grooves required for repair welding cannot be machined, secondary defects cannot be accurately removed, etc., and are conducive to repairing. Quality, accurate removal, and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

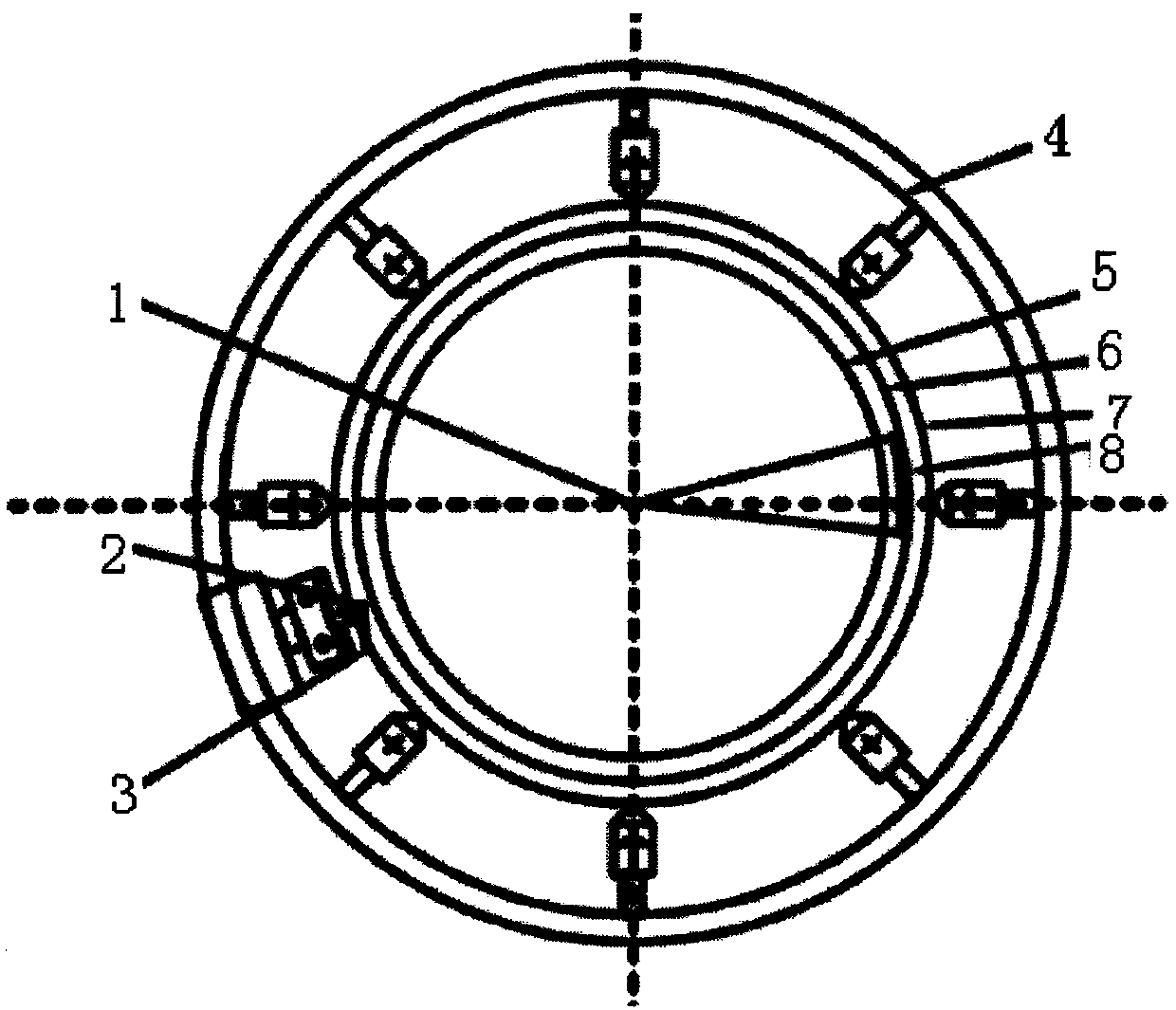

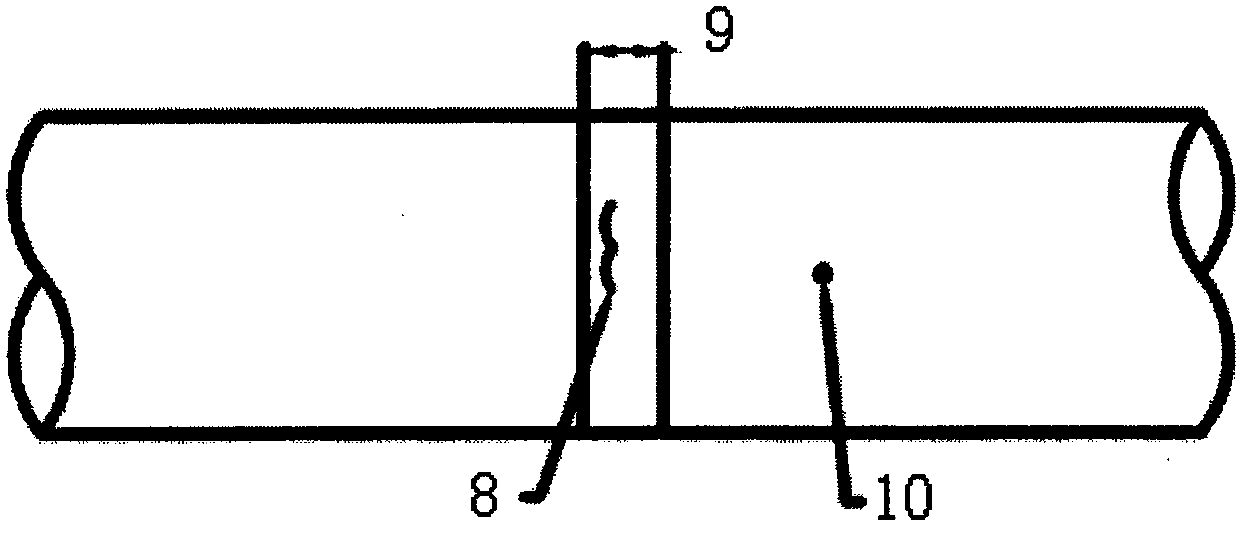

[0061] refer to Image 6 , the embodiment of the present invention provides a narrow gap automatic welding seam repair method for large pipelines, the steps are:

[0062] S1. Locate the defects of the pipeline welds, and use the positioning points set before welding on the pipelines to mark the weld defects on the pipeline entity;

[0063] Positioning point: After the weld seam is welded, the surface of the weld seam needs to be polished to be as smooth as the base metal. Most of these weld seams need to be inspected in service. Before welding, make a small pit on the pipe as the positioning point. After recording the distance between the positioning point and the weld seam, after the weld seam is polished, the specific position of the weld seam can be accurately found by the distance from the positioning point;

[0064] S2. Based on the result of defect location, excavate the pipeline defect and the heat-affected zone of the original weld;

[0065] S3. After the pipeline de...

Embodiment 2

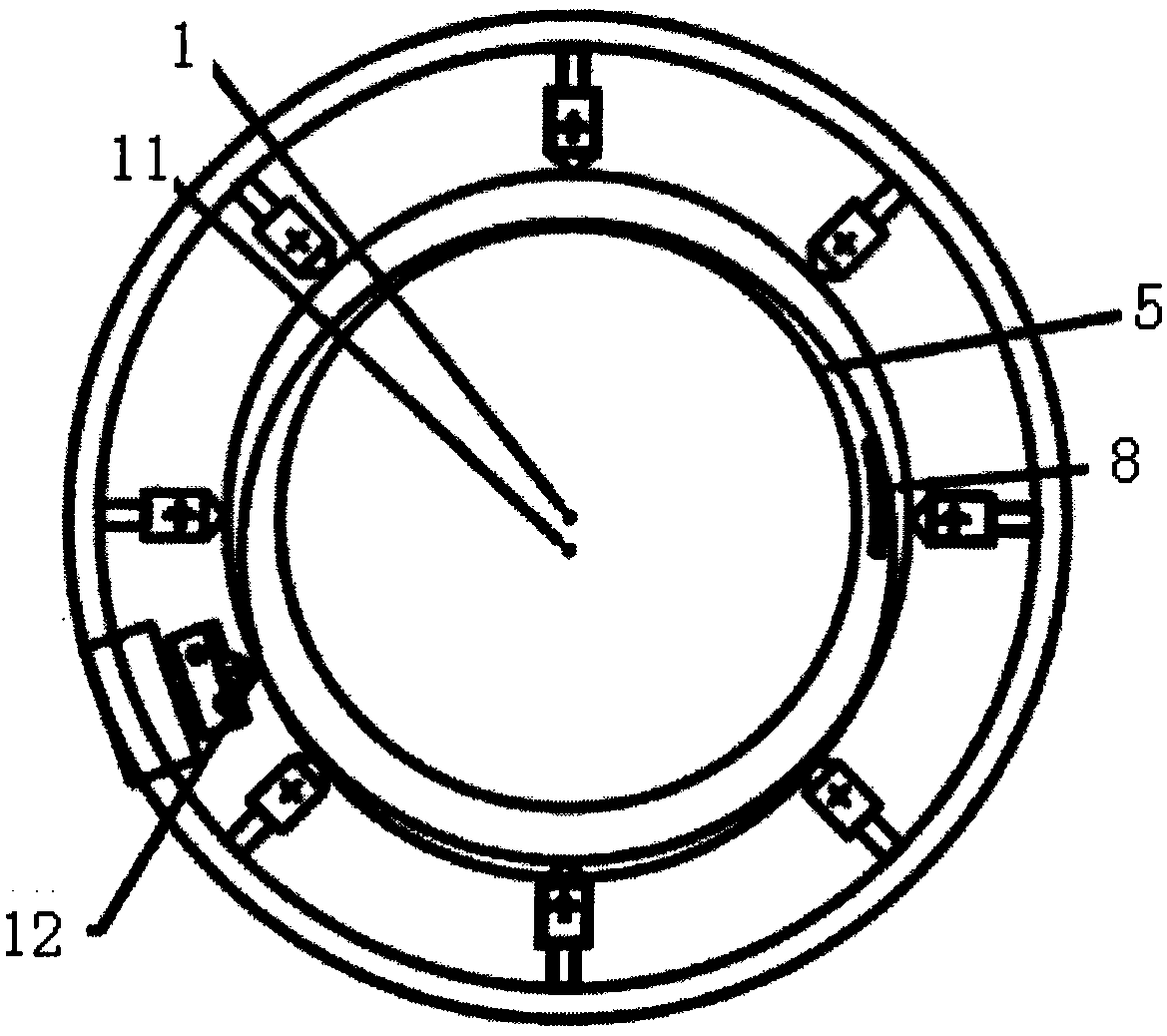

[0092] Based on the same inventive concept, an embodiment of the present invention also provides a narrow-gap automatic weld seam repair system for large pipelines. The repair system includes:

[0093] The welding seam positioning module is used to locate the defect of the narrow gap automatic welding seam, and use the positioning point set on the pipeline before welding to mark the welding seam defect on the pipeline entity;

[0094] Weld defect excavation module is used to excavate pipeline defects and original weld heat-affected zone based on the result of defect location;

[0095] The weld groove processing module is used to process the weld groove of the pipeline after the pipeline defect is excavated;

[0096] The welding seam repairing module is used for repairing welding seams of pipes after the groove processing is completed.

[0097] In the specific implementation process, the defect removal module uses groove processing equipment to remove pipeline defects and orig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com