Wheel rim driven speed reducer of AGV trolley

A technology of wheel side and reducer, which is applied in the direction of gear transmission, mechanical equipment, transmission, etc., can solve the problems of complex connection with the wheel and suspension system, the reduction of the reducer can not meet the needs of customers, and large temporary space, etc., to achieve Improved rigidity, large torque, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

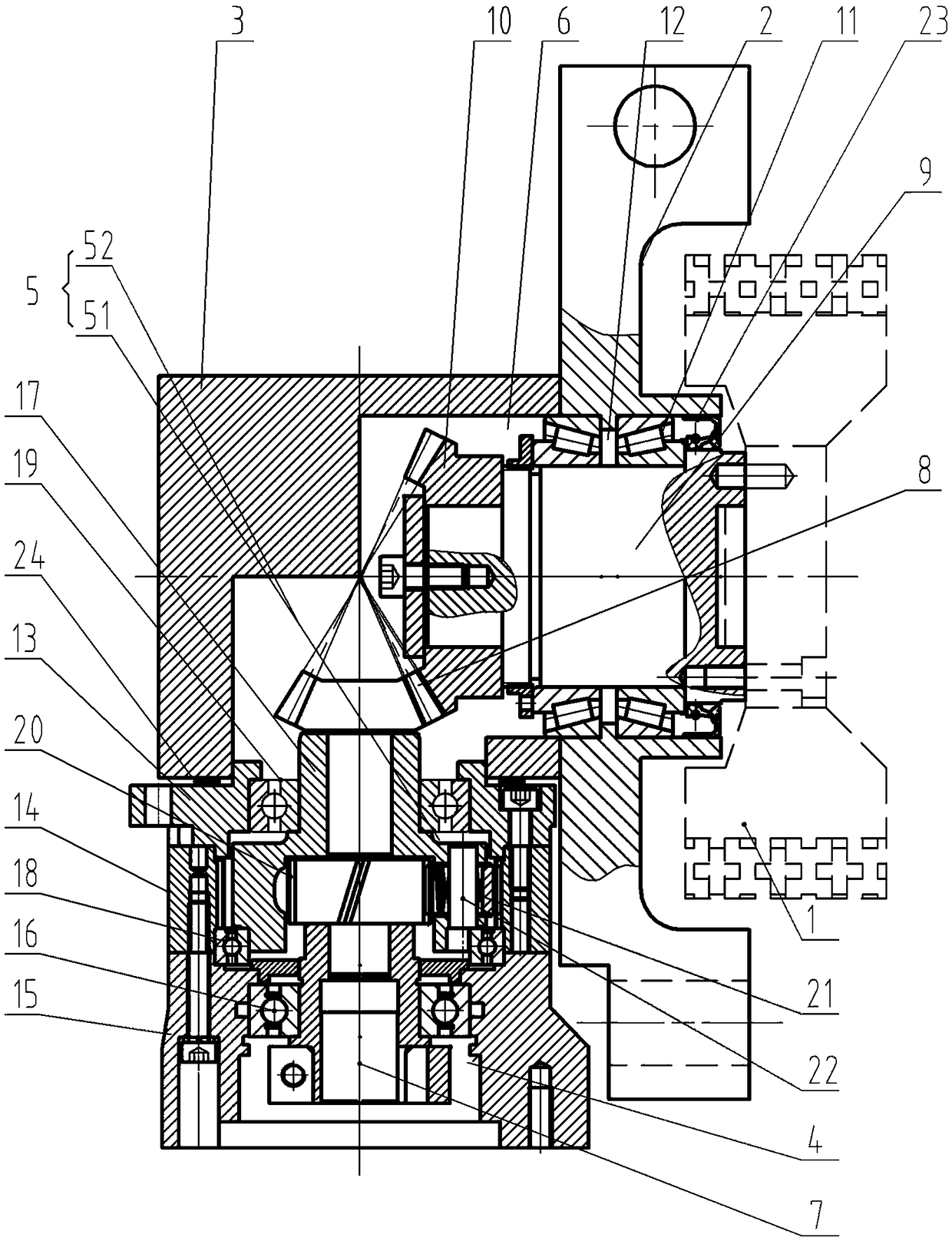

[0014] A reducer driven by AGV trolley wheels, see figure 1 : It includes a wheel 1, a suspension flange 2, a reduction box body 3, the suspension flange 2 is arranged on the inner side of the wheel 1, the suspension flange 2 is connected to the vehicle body, and the inside of the reduction box body 3 includes an input cavity 4 and a transmission cavity Body 5, output cavity 6, the output part of the input shaft 7 is placed in the input cavity 4, the input cavity 4 is arranged perpendicular to the output cavity 6, the transmission cavity 4 is provided with a planetary deceleration structure, and the output of the planetary deceleration structure The end is provided with a bevel gear shaft 8, which also includes an output shaft 9, the input part of the output shaft 9 is located in the output cavity 6, and the input part of the output shaft 9 is covered with a bevel gear 10, and the bevel gear 10 is meshed with the bevel gear shaft 8 The corresponding bevel gear on the top, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com