Pickup device for straw and grass

A pasture and straw technology, which is applied in the field of straw and pasture picking devices, can solve problems such as easy to block, affect bundling efficiency, and difficult to maintain, and achieve the goal of preventing accumulation or blocking of materials, simple production process, compact and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

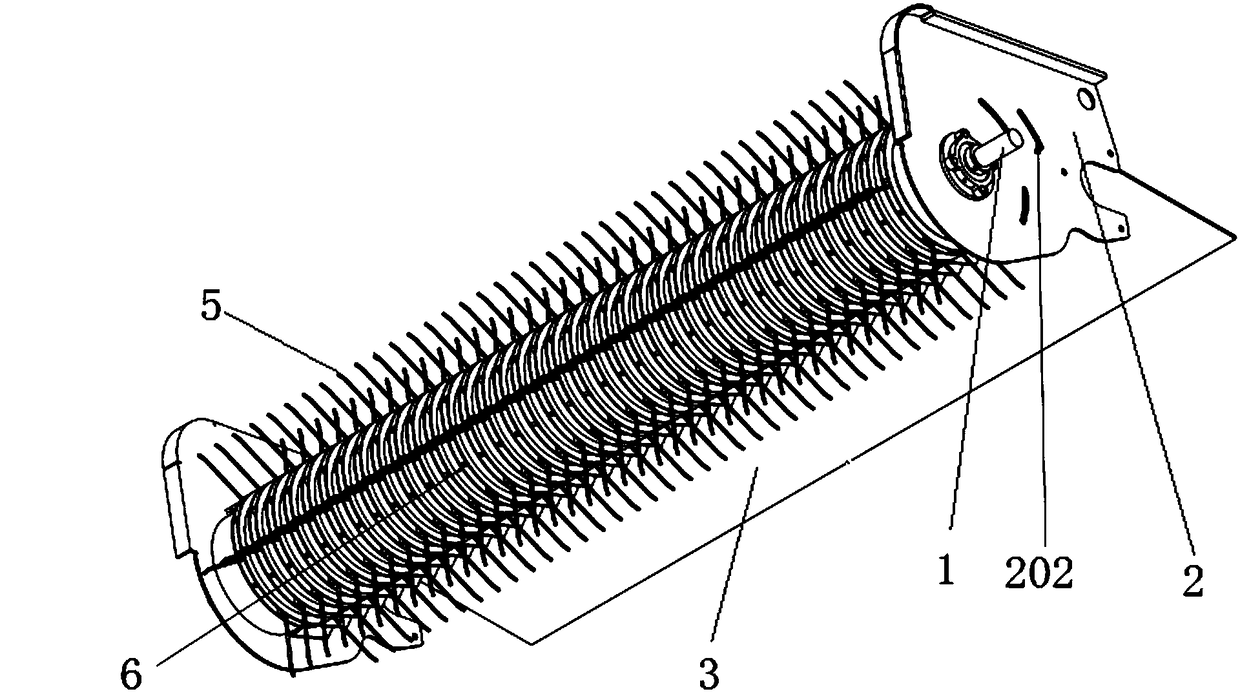

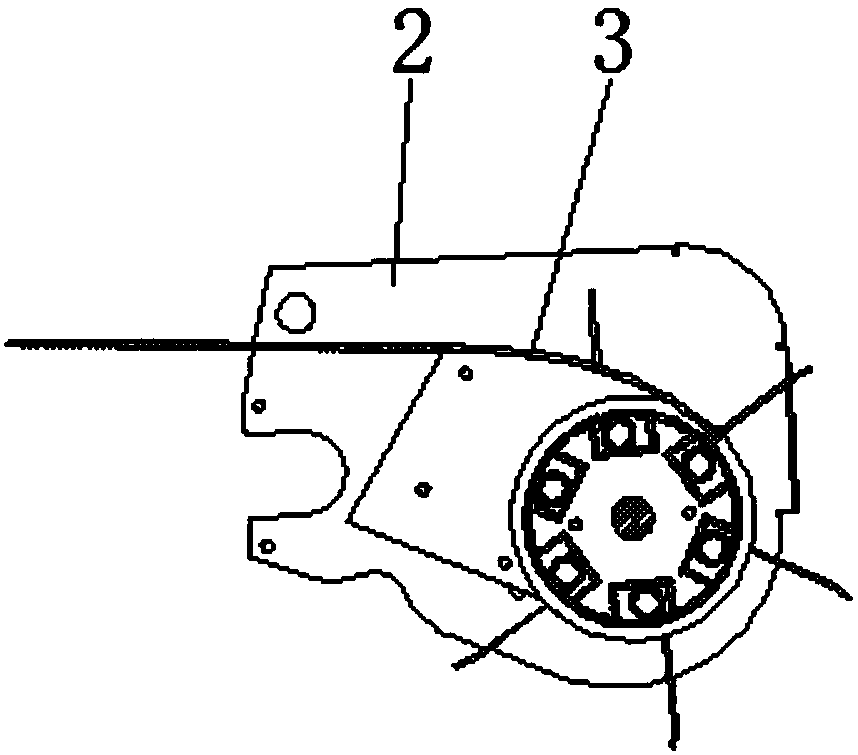

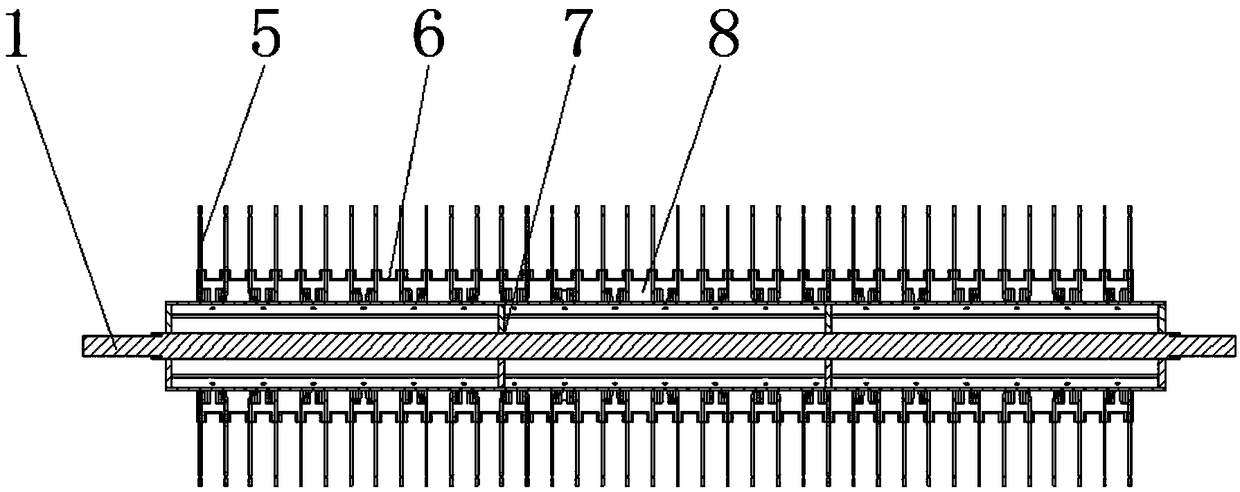

[0026] Such as figure 1 As shown in —11, a pick-up device for straw and forage grass includes a main shaft 1, a pick-up side plate 2, a pick-up rolling part 4, and a grass-following plate 3, the grass-following plate 3 is located above the picking-up rolling part 4, and the grass-following plate 3 The adjustable connection is on the pick-up side panel 2.

[0027] Picking up the rolling part 4 includes at least two chucks 7. In order to pick up the rolling part 4 with a stable and reliable structure, in this embodiment, four chucks 7 are specifically set, and the chucks 7 are uniformly welded and fixed on the main shaft 1 with the same axis. The chuck 7 is provided with a plurality of spring tooth seats 8, each of the spring tooth seats 8 is provided with a number of hoops 6 and spring teeth 5, and the spring teeth 5 are fixed to the spring tooth seats 8 by bolts, each The spring teeth 5 all include two spring racks 501, and a hoop 6 is set between the two spring racks 501 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com