Transparent silver-black three-color multifunctional composite mulching film and manufacturing method thereof

A manufacturing method and multi-functional technology, applied in chemical instruments and methods, botanical equipment and methods, flat products, etc., can solve the problems of poor light reflection performance of black mulch film, no anti-disease and insect pest function, no weeding function, etc. The effect of reducing pesticide residues, reducing farmers' production costs and increasing farmers' income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

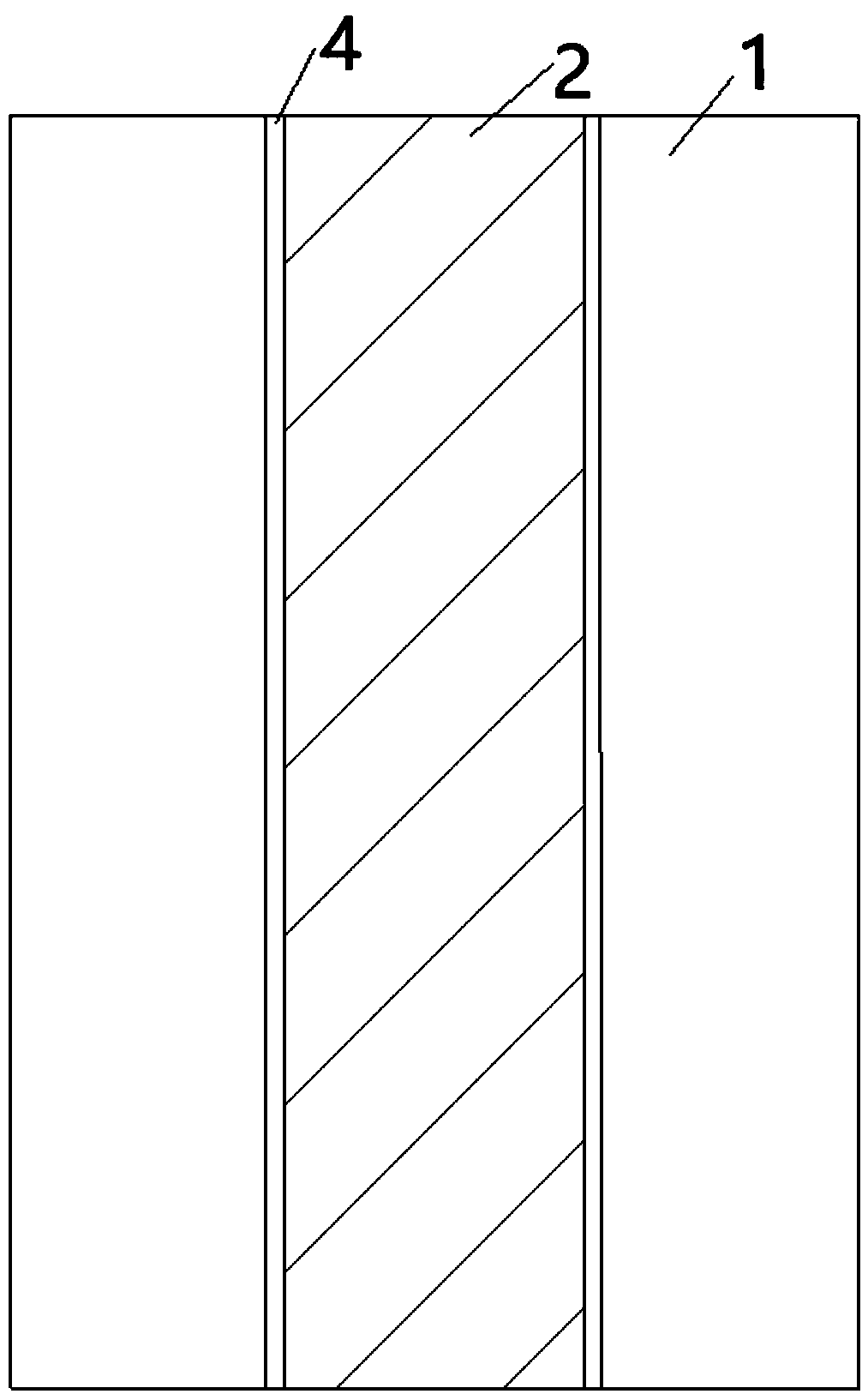

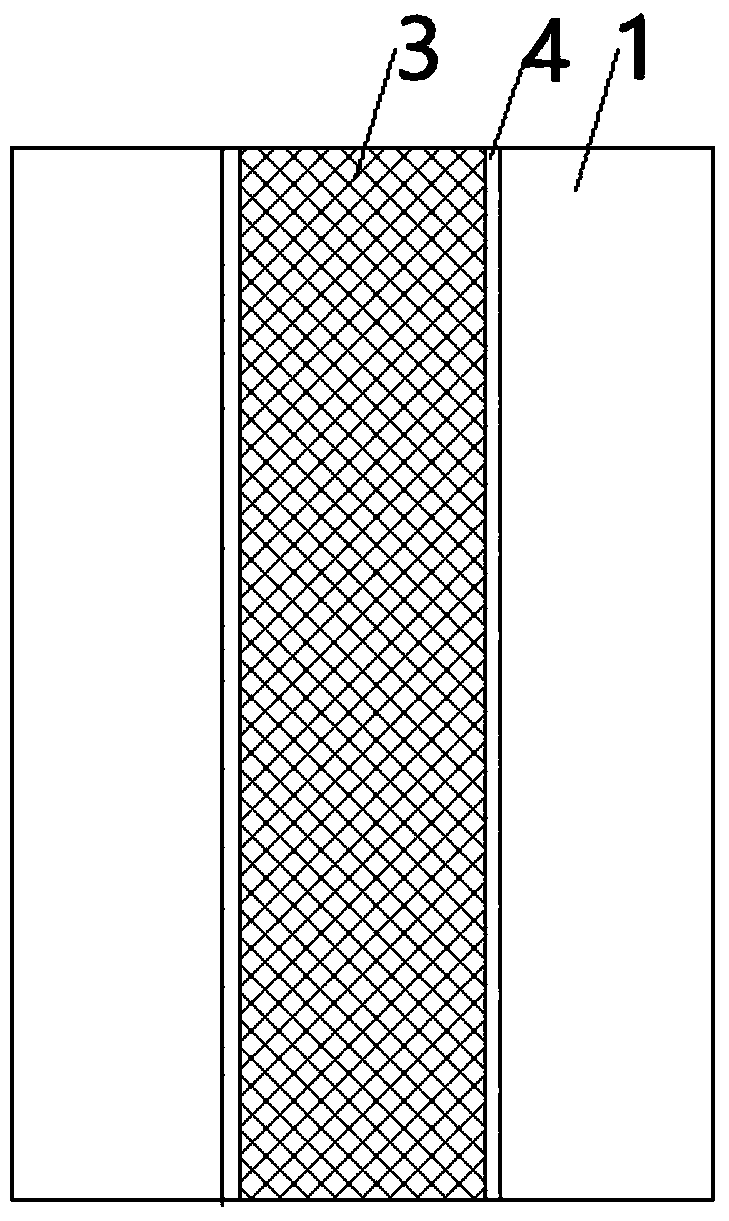

[0019] A kind of transparent silver and black three-color multifunctional composite plastic film, see figure 1 , the composite mulching film includes transparent film bodies 1 on the left and right sides, and the silver film body 2 on the top and the black film body 3 on the bottom are connected between the transparent film bodies 1 on the left and right sides, see figure 2 , the right side of the transparent film body 1 on the left and the left side of the transparent film body 1 on the right are respectively crossed between the silver film body 2 and the black film body 3 through thermoplastic extrusion molding to form an integrated composite structure; the transparent film A protective tape 4 is connected between the body 1 and the silver film body 2 and the black film body 3 .

[0020] In the transparent silver-black three-color multi-functional composite mulch film of this embodiment, crops are planted in 1 place of its transparent film body, which absorbs sunlight durin...

Embodiment 2

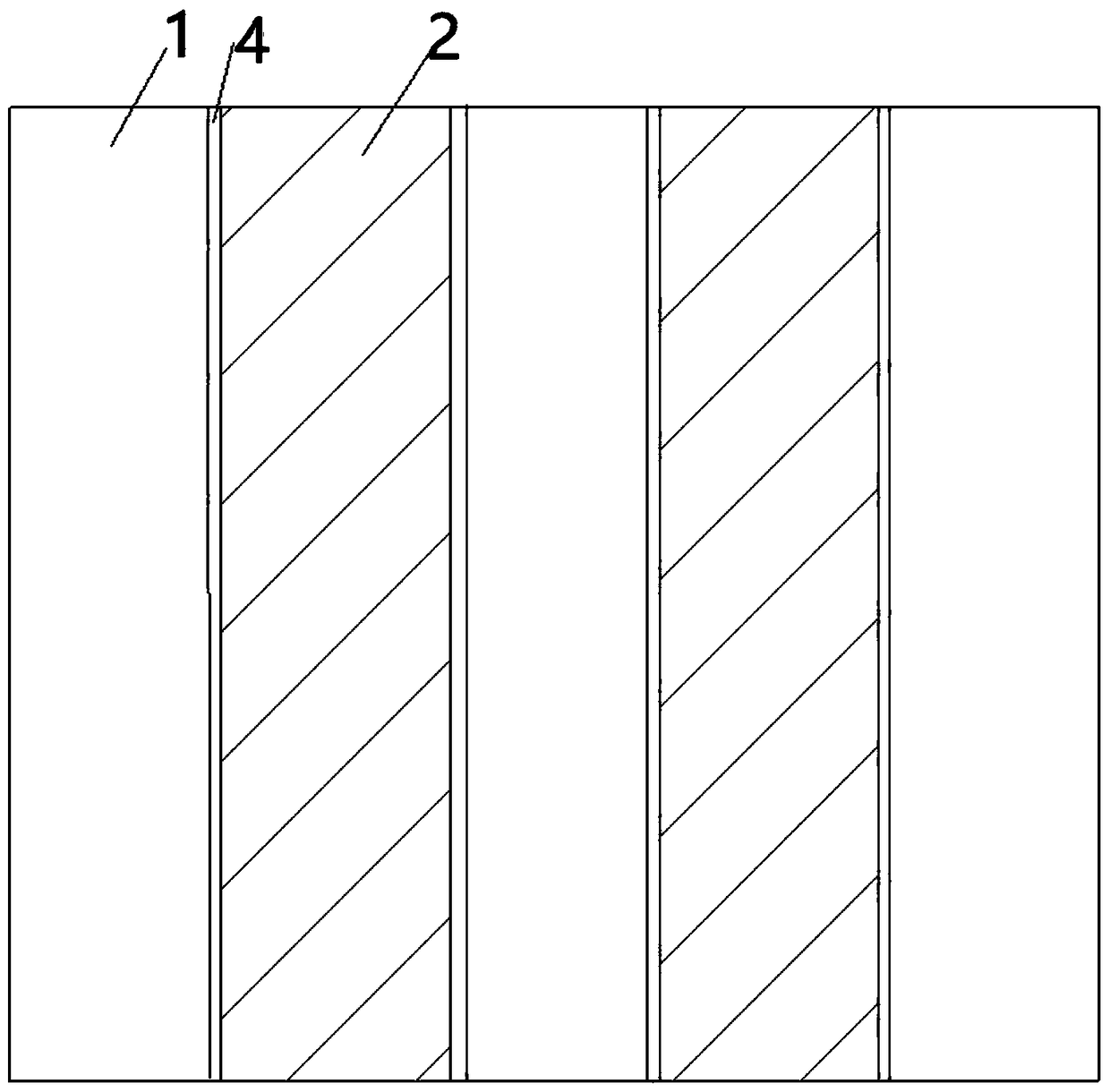

[0026] A kind of transparent silver and black three-color multifunctional composite plastic film, see image 3 , Similar to Example 1, the difference is that there are two silver film bodies 2 and two black film bodies 3 respectively, and two silver film bodies 2 and black film bodies 3 are distributed side by side in the left and right directions.

[0027] In this way, the number and coverage area of the transparent film body 1 between the silver film body 2 and the black film body 3 can be increased, which is suitable for the planting needs of larger crops.

Embodiment 3

[0029] A kind of transparent silver-black three-color multifunctional composite mulching film, similar to embodiment 1, the difference is, see Figure 4 , the left side and the right side of the composite plastic film are provided with at least two pairs of tear openings 5 at intervals, and the composite plastic film between each pair of tear openings 5 is provided with a tear line 6 . In this way, during use, the composite plastic film of required length can be intercepted according to needs, and when intercepted, it is torn through the tear opening 5, so that the composite plastic film is torn through the tearing line 6 to cut off the composite plastic film. to the desired length.

[0030] It should be noted that the tearing line 5 here may be at least two through holes arranged at intervals. The through holes may be strip holes. The strip-shaped holes may be rectangular holes. The sides of the two ends of the rectangular hole in the length direction may be arc-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com