Quick flocculator in fluid catalytic cracking slurry sedimentation tank and manufacturing method

A technology of catalytic cracking oil slurry and flocculator, which is applied in the direction of chemical instruments and methods, settling tanks, separation methods, etc., to achieve good economic benefits, reduce investment, and improve the effect of sedimentation and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

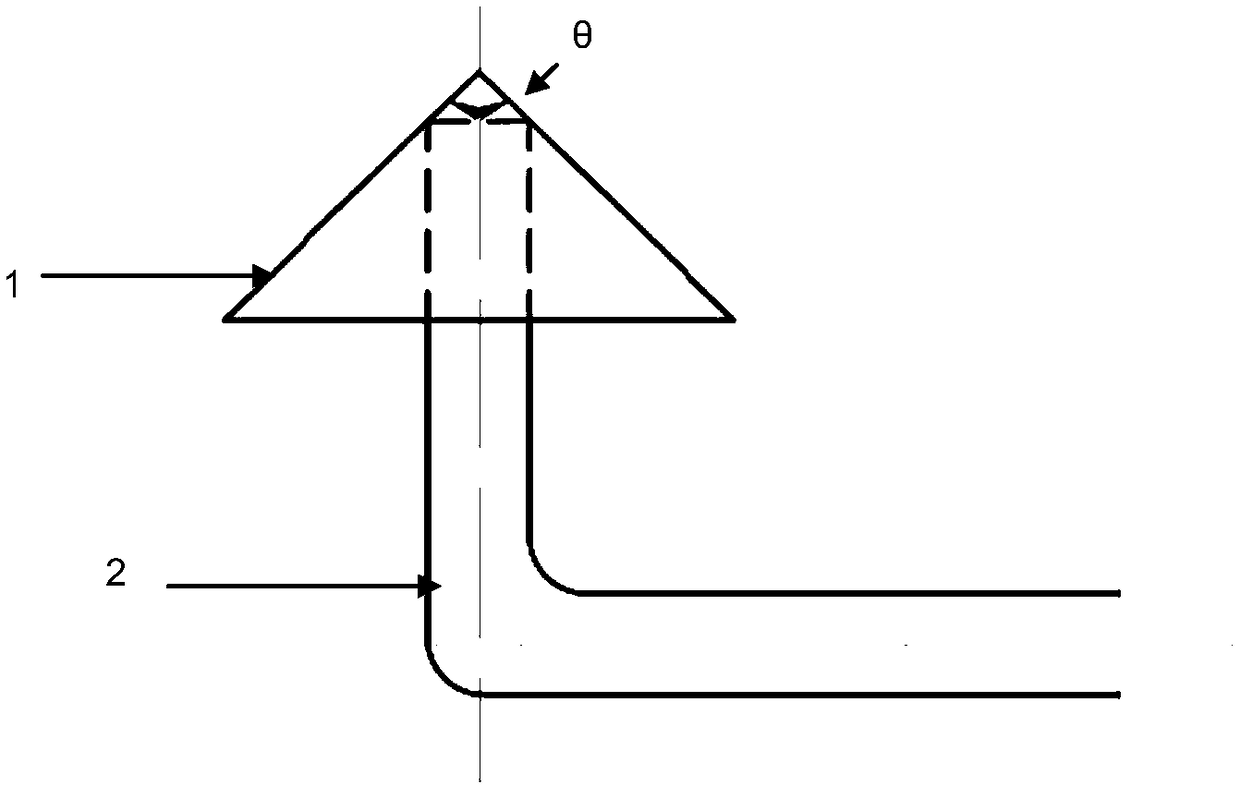

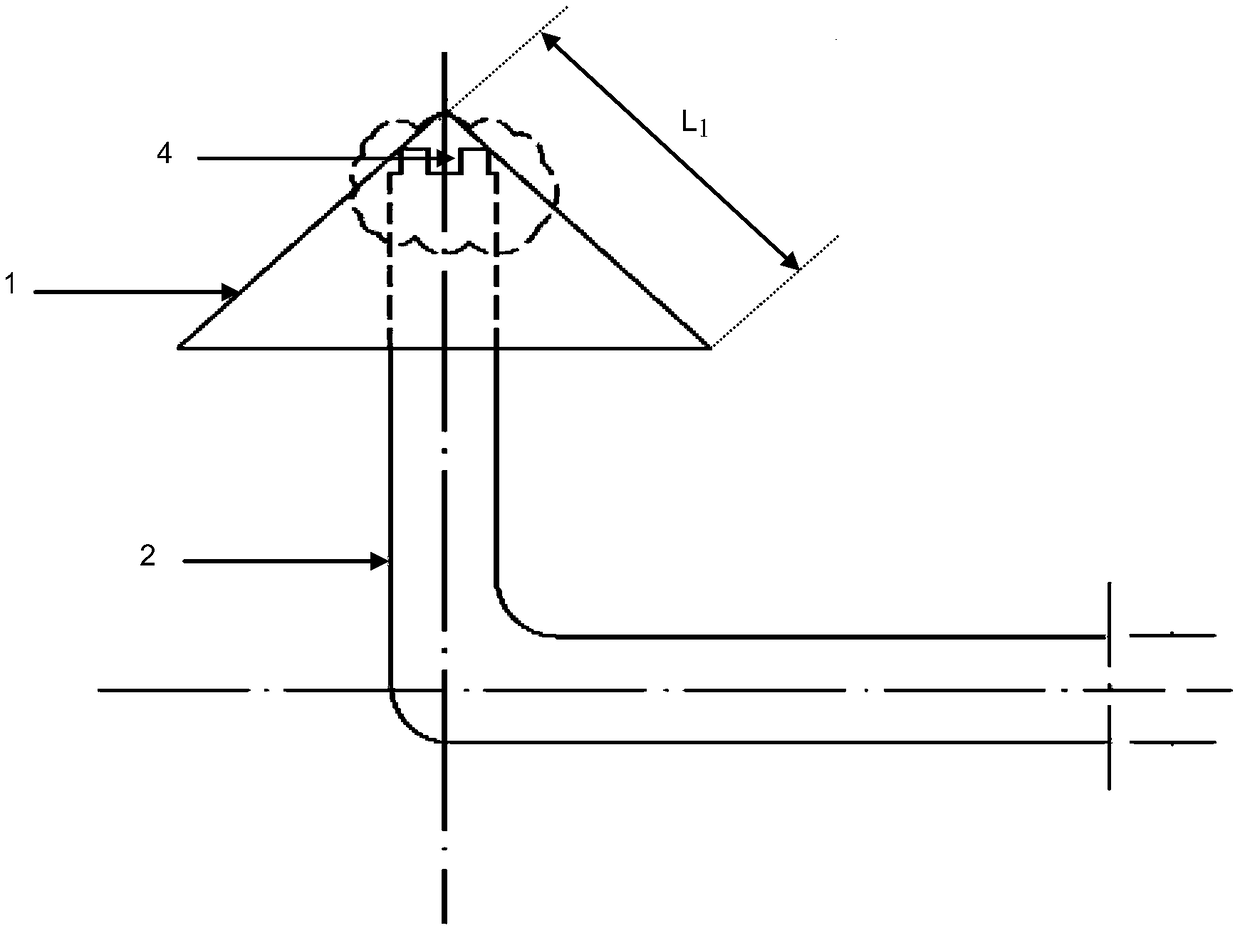

[0094] Such as Figure 1-5 As shown, this embodiment provides a fast flocculator for use in a sedimentation tank of a catalytic cracking oil slurry, which includes a working cavity (that is, the flocculator body) and a draft tube 2. The working cavity is a hollow cone 1, so The cone 1 includes a side panel and a bottom panel. A number of notches are cut along the edge of the bottom panel as the flocculator discharge port 3, and a circular hole is cut with the center of the bottom panel as the guide tube insertion port. The guide tube 2 is a hollow pipe. The tail end of the pipeline is cut with a number of grooves along the pipe wall. The tail end of the guide tube 1 passes through the guide tube insertion port and then welds to the inner wall of the side panel. The groove is at the top of the inner side of the cone 1 and serves as the flocculator feed port 4.

[0095] Preferably, the axial section of the cone 1 is an isosceles triangle with a top angle θ of 90°, and the included...

Embodiment 2

[0102] This example provides a set of basic parameters for designing the fast flocculator in the FCC slurry sedimentation tank:

[0103] A. Residence time, the residence time T of the oil slurry in the working cavity is 3-10 seconds, preferably 5 seconds;

[0104] B. The feed flow rate of the flocculator, the flow rate of the oil slurry into the flocculator 1 Use 1-2.5 m / s, preferably 1 m / s;

[0105] C. The flow rate of the flocculator, the flow rate of the oil slurry out of the flocculator v 2 1-3.5 m / sec, preferably 2.5 m / sec;

[0106] D. The treatment capacity of the flocculator, the treatment capacity Q under actual application conditions, in meters 3 / second.

[0107] Where T, v 1 , V 2 In specific applications, it is pre-selected according to actual working conditions and requirements, and Q is the processing capacity under actual working conditions.

Embodiment 3

[0109] On the basis of the combination of Examples 1 and 2, the present invention also provides a method for manufacturing a fast flocculator used in a sedimentation tank for catalytic cracking oil slurry:

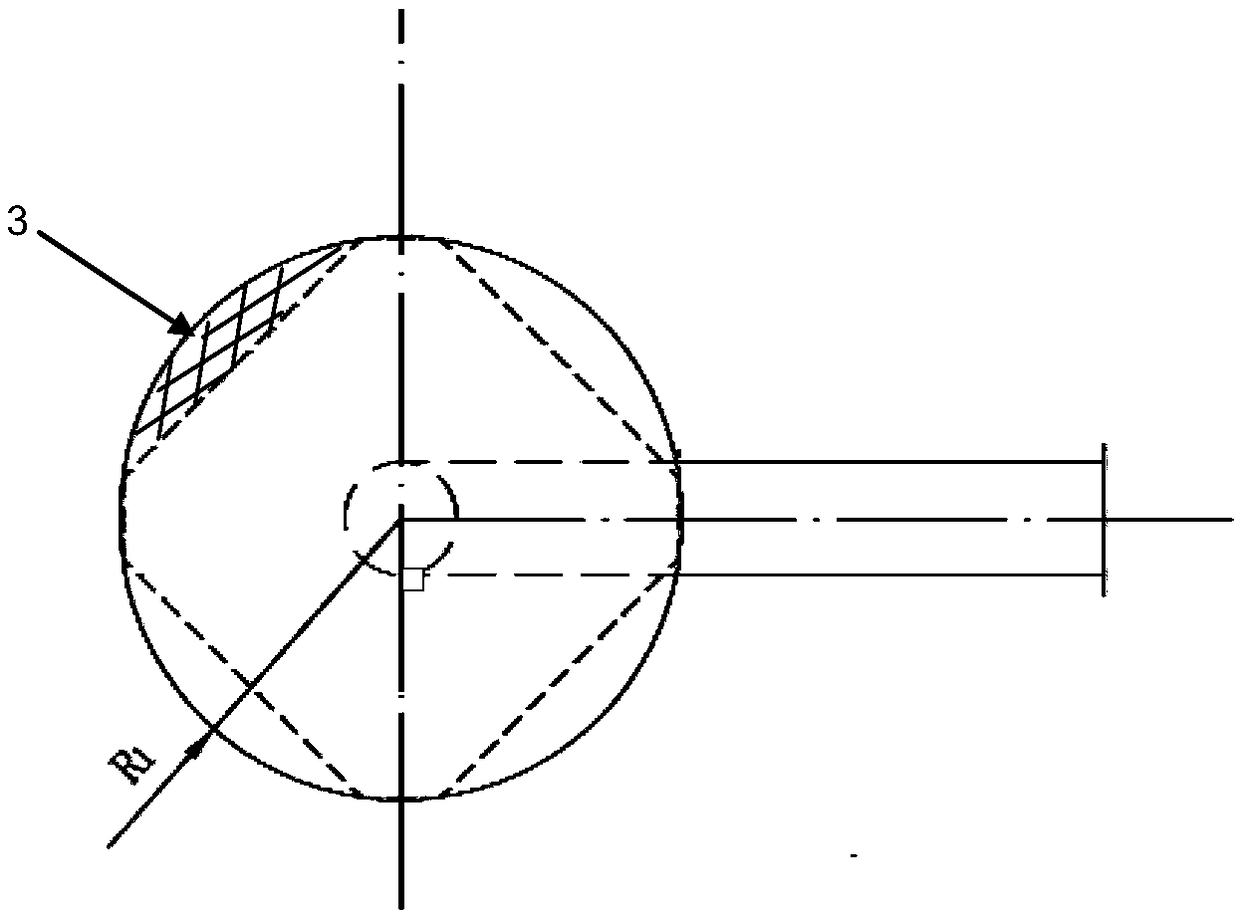

[0110] Step 1. Calculate the overall dimensions of the flocculator: Based on the treatment capacity Q and residence time T of the flocculator, calculate the bus length L of the cone 1 And the radius of the bottom panel R 1 .

[0111] Step 2: Calculate the flow area of the flocculator's feed inlet: the flow area of the flocculator's feed inlet is the flow area of the draft tube oil slurry into the working chamber, and the flocculator's feed flow rate v 1 And the processing capacity Q of the flocculator is calculated based on the flow area S of the flocculator inlet 1 .

[0112] Step 3. Calculate the flow area of the flocculator outlet: the flow area of the flocculator outlet is the flow area of the oil slurry in the working chamber entering the settling tank, and the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com