Alkyl fatty ester preparing process

A technology of fatty acid alkyl esters and manufacturing methods, which is applied in the field of fatty acid alkyl esters, can solve the problems of oil raw materials that are difficult to correspond to the range of acid value fluctuations, high wastewater treatment costs, and low production efficiency, so as to solve the problem of sewage discharge and save operation The effect of cost and process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

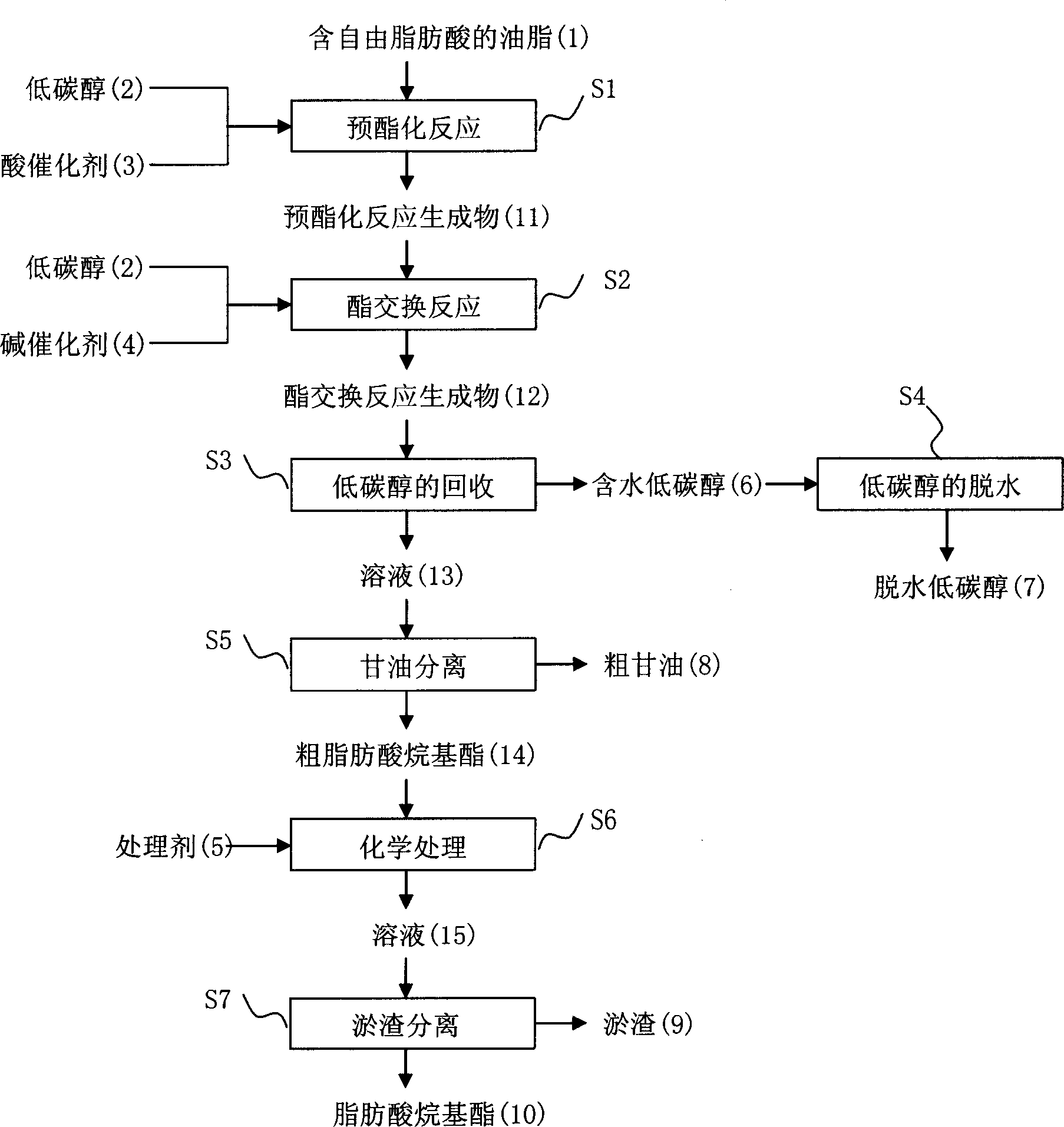

[0118] Using dehydrated waste cooking oil (moisture 450ppm, acid value 98mg-KOH / g) under the condition of 90°C and 5mmHg as raw material, according to figure 1 The technological process produced fatty acid methyl ester. The detailed description of the preparation process is as follows:

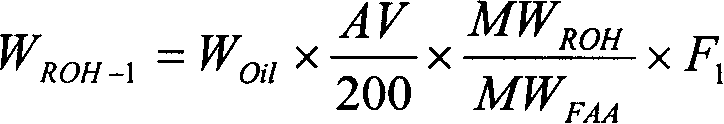

[0119] Above-mentioned waste edible oil 100kg is packed in the retort of band stirrer and electric heater, and add in retort, calculate by calculation formula 1, purity is 99.8% methyl alcohol 56.6kg (F 1 =10) and the concentration calculated by calculation formula 2 is 95% sulfuric acid catalyst 1kg (F 2 =0.056), and stirred at 65° C. for 120 minutes to obtain a pre-esterification reaction product. Adding in the esterification reaction product then is that the potassium hydroxide 1.8kg (F 4 =0.2), and stirred at 65° C. for 30 minutes to obtain a transesterification reaction product. The transesterification reaction product was put into an evaporating tank equipped with a stirrer, and the ...

Embodiment 2

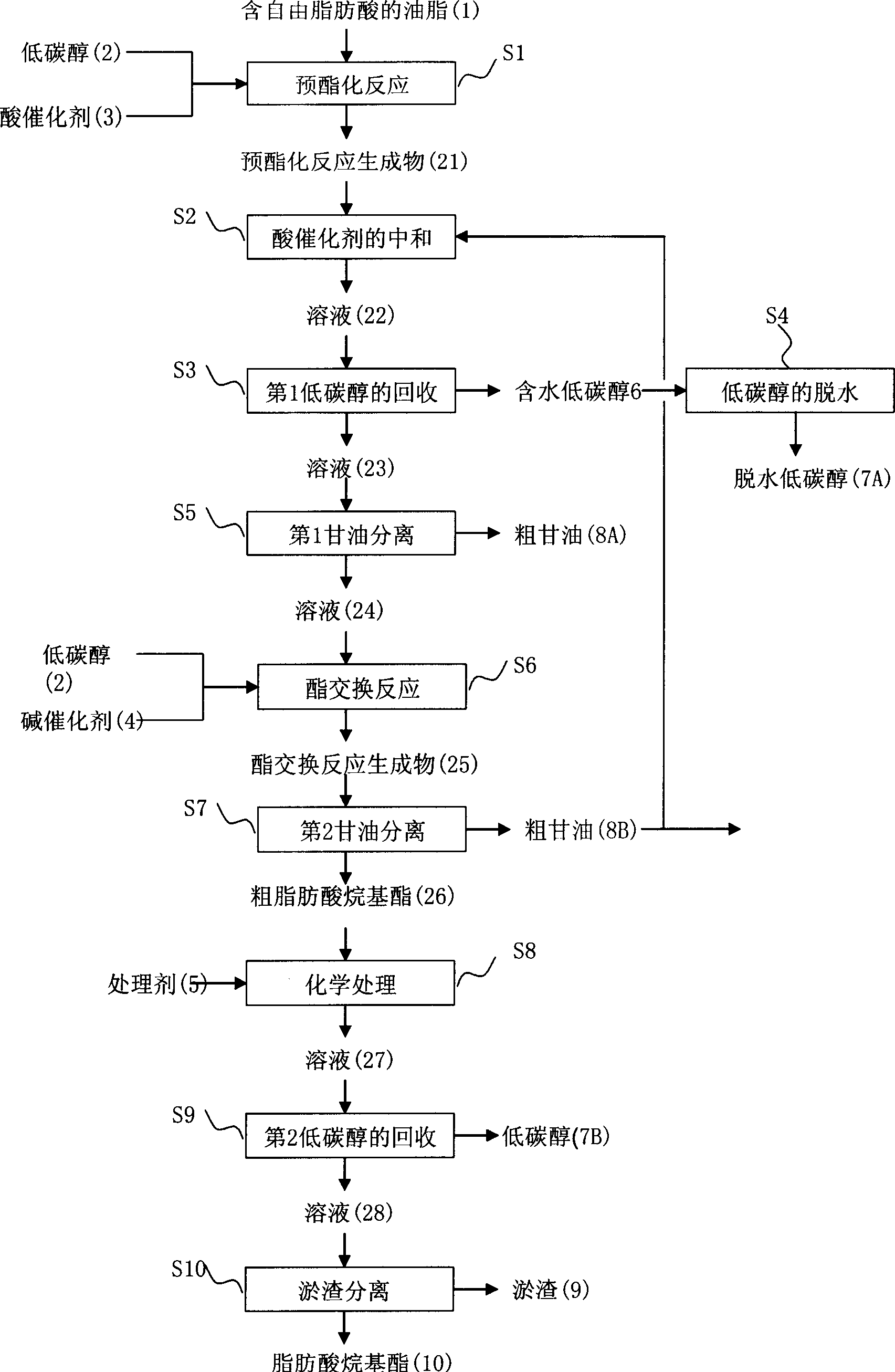

[0121] Using dehydrated waste cooking oil (moisture 450ppm, acid value 98mg-KOH / g) under the condition of 90°C and 5mmHg as raw material, according to figure 2 The technological process produced fatty acid methyl ester. The detailed description of the preparation process is as follows:

[0122] Above-mentioned waste cooking oil 100kg is packed in the retort of band stirrer and electric heater, and in retort, add calculates by calculation formula 1, and purity is 99.8% methyl alcohol 56.6kg (F 1 =10) and the concentration calculated by calculation formula 2 is the amount 1kg (F of the sulfuric acid catalyst of 95%) 2 =0.056), and stirred at 65° C. for 120 minutes to obtain a pre-esterification reaction product. Then add 21kg of crude glycerin (composition: KOH 5%, glycerol 48%, moisture 2%, other 45%) containing alkali catalyst to the esterification reaction product, and stir for 5 minutes under the condition of 65 ℃ to obtain the mixed mixture A. Put it into an evaporating...

Embodiment 3

[0124] The used raw material grease of embodiment 3, low carbon alcohol, alkali catalyst and acid catalyst are the same as embodiment 1. The process of producing fatty acid methyl esters from raw oils and fats is basically the same as in Example 1, except that after the chemical treatment, 5% water equivalent to the volume of the solution was added to solution 1 and stirred for 5 minutes. The rest time after chemical treatment was 30 minutes. In addition, after the sludge was separated and removed, the solution was further vacuum-dried and dehydrated at 90° C. and 5 mmHg for 30 minutes to finally obtain the fatty acid methyl ester product. The properties analysis results of fatty acid methyl esters are shown in Table 1. As shown in Table 1, by adding water after the chemical treatment, although the static separation time is only 30 minutes, the impurity content in the product is lower than that obtained in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com