Microreaction chip, microfluidic mixing method and preparation method thereof

A micro-reaction and micro-fluid technology, applied in mixers, chemical instruments and methods, chemical/physical/physicochemical reactors, etc., can solve problems affecting production and limiting the effective length of micro-reaction channels, so as to increase production and prolong Micro-reaction channels, the effect of reducing occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

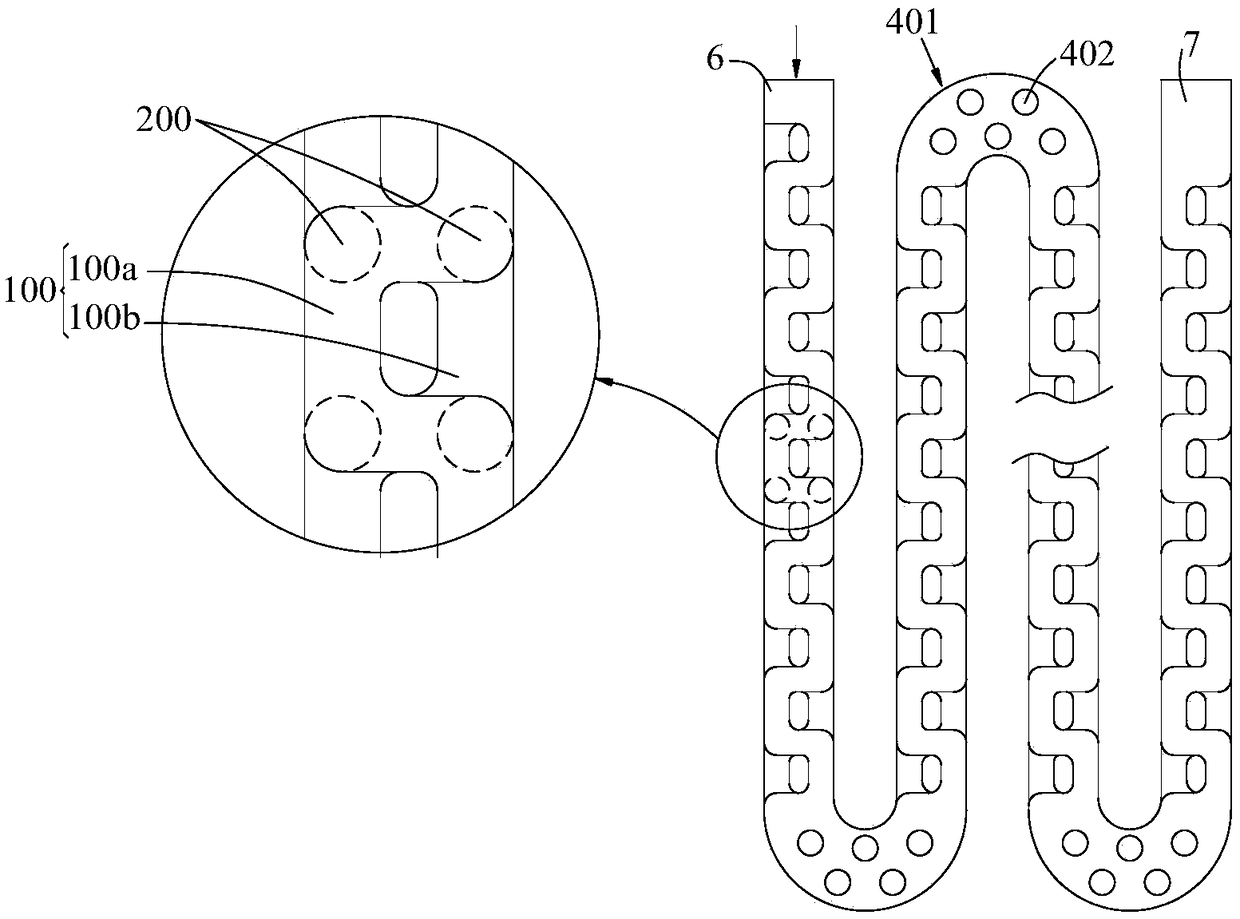

[0066] figure 1 It is a structural schematic diagram of an embodiment of a micro-reaction chip of the present invention.

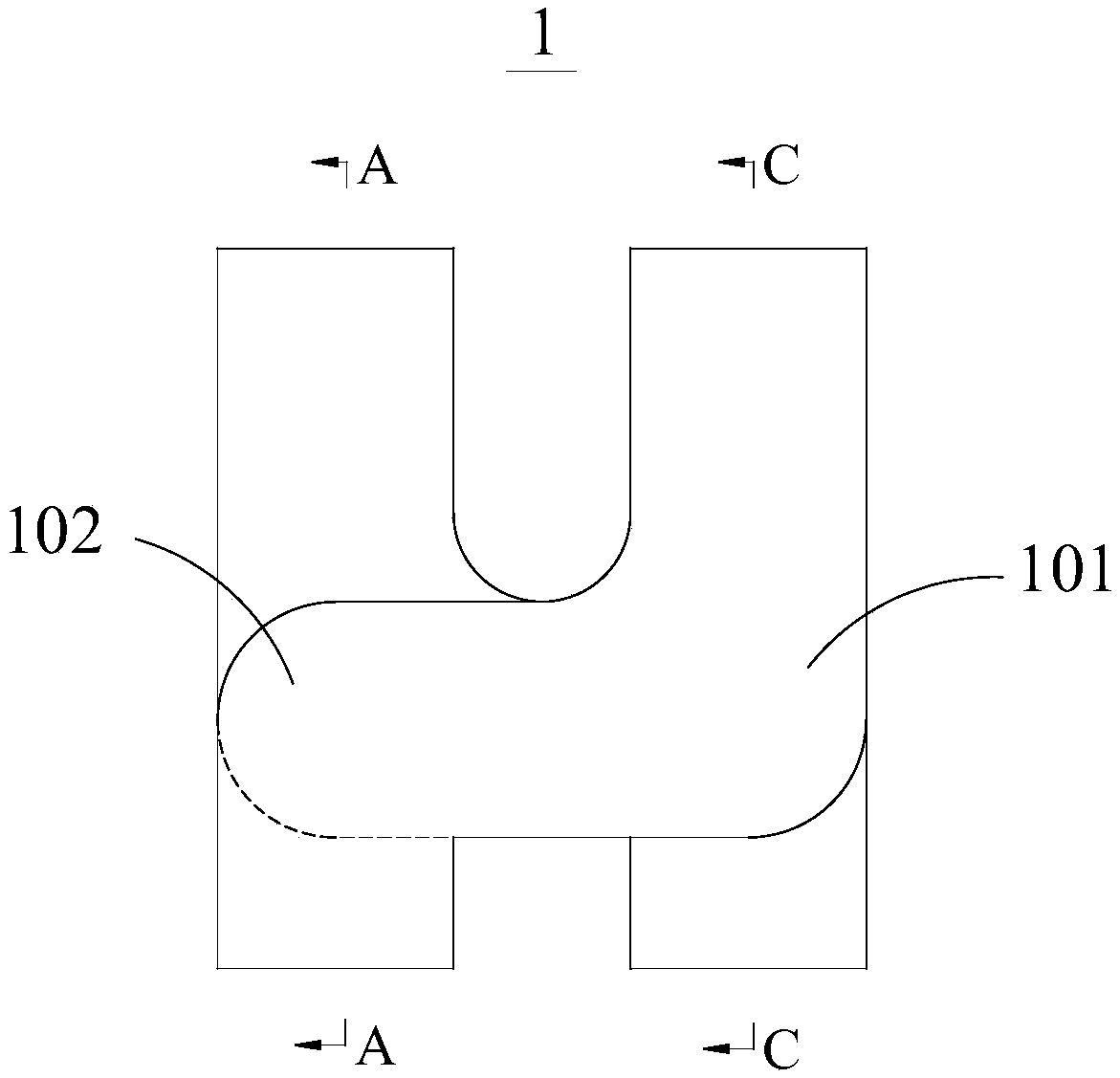

[0067] figure 2 It is a structural schematic diagram of the micro-reaction channel unit in the first embodiment of the present invention.

[0068] Such as figure 1 and figure 2 As shown, the present embodiment 1 provides a microreaction chip, including a microreaction channel unit 1; the microreaction channel unit 1 includes: two microchannels 100 stacked up and down, and the two microchannels 100 communicate with each other to The fluids in the two microchannels 100 are mixed with each other. After two different fluids are injected into the micro-reaction chip from the liquid inlet 6 , they are fully mixed by at least one micro-reaction channel unit 1 , and then discharged from the liquid outlet 7 . The micro-reaction channel unit 1 is the smallest unit of the micro-reaction chip, and the micro-reaction chip can complete a complete reaction channel...

Embodiment 2

[0100] see Figure 1 to Figure 10 , on the basis of Example 1, this Example 2 provides a microfluidic mixing method.

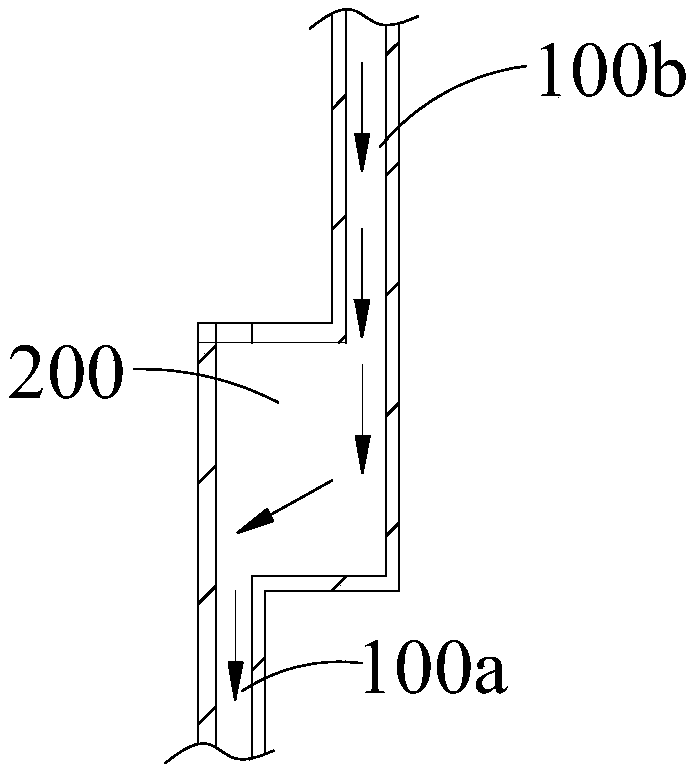

[0101] The two micro-channels 100 are stacked and communicated with each other, so that the fluids in the two micro-channels 100 cross and mix with each other during travel.

[0102] A set of convection holes 200 suitable for fluid back-and-forth crossing is communicated between the two micro-channels 100 , and a set of convection holes 200 includes two convection holes 200 , so that the fluids in the two micro-channels 100 are mixed back and forth.

[0103] In this embodiment, the specific structure and working principle of the micro-channel 100 have been described in detail in Embodiment 1 above, and will not be repeated here.

[0104] The beneficial effect of the present invention is that this mixing method, firstly, by stacking two micro-flow channels, the occupancy of the plane space is reduced, the three-dimensional space is rationally used, and the mic...

Embodiment 3

[0106] On the basis of Example 1, this Example 3 also provides a method for preparing a micro-reaction chip.

[0107] Specifically, the micro-reaction channel unit 1 adopts a multi-layer arrangement, and includes an intermediate layer and an upper and a lower layer, wherein on the contact surfaces of the upper, lower layer and the intermediate layer, there are respectively provided micro-reaction channel units along the micro-channel 100 in the micro-reaction channel unit. grooves; the middle layer corresponding to the micro-reaction channel unit 1 is provided with at least one set of convection holes 200; Through a set of convection holes 200, the two fluids pass back and forth between the two micro-channels to realize cross-mixing.

[0108] The preparation method of the micro-reaction chip has quick preparation and good preparation effect.

[0109] In summary, the micro-reaction chip uses the double-layered micro-channel 100 and the convection hole 200 to realize the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com