Pretreatment device used before solid garbage transportation

A pretreatment device and technology for solid waste, applied in solid separation, grain treatment, sieving, etc., can solve the problems of complicated procedures, no flow treatment, and no separation of waste liquid, so as to improve the extrusion effect and the pulverization effect. and efficiency, the effect of improving the crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

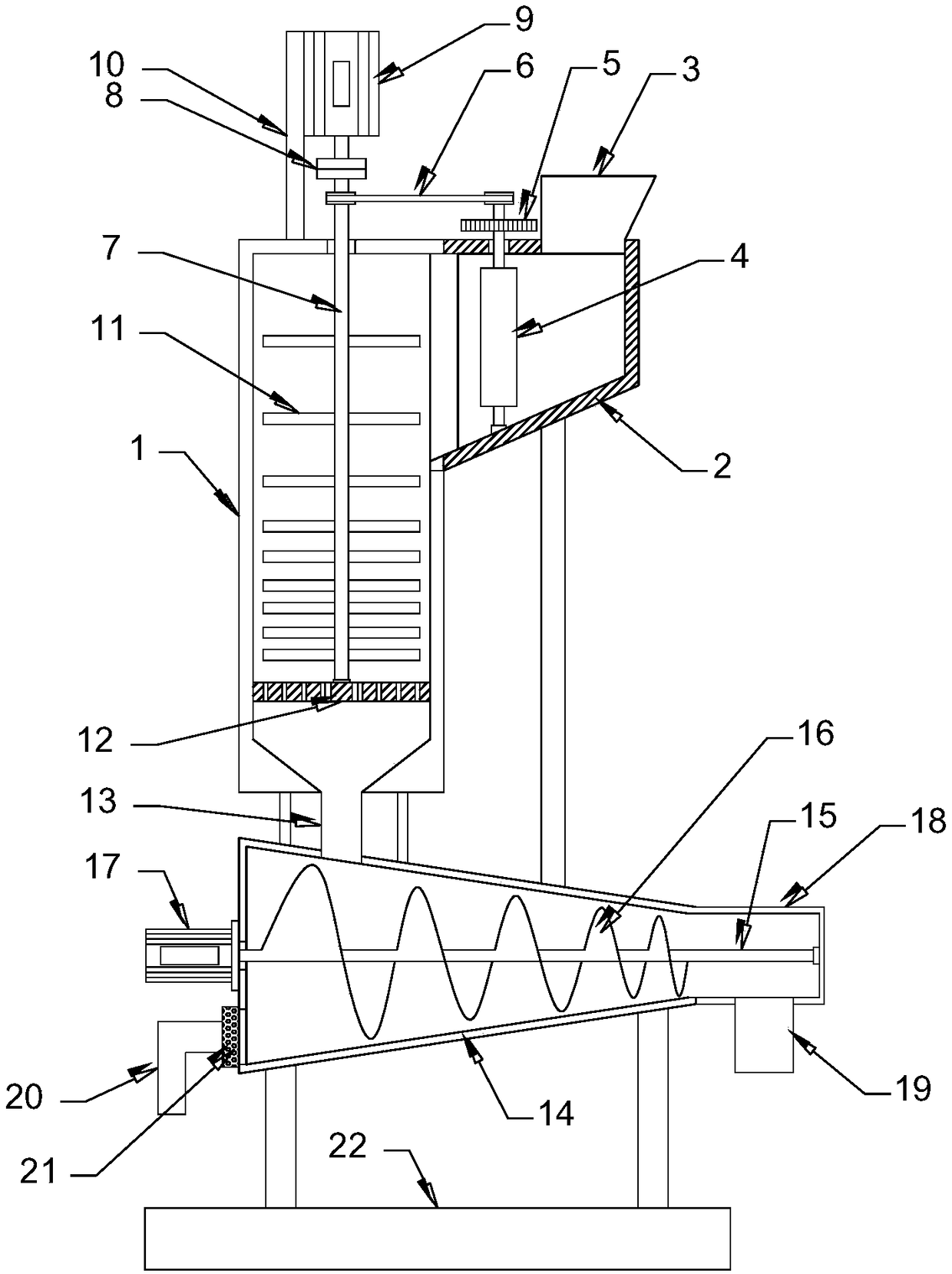

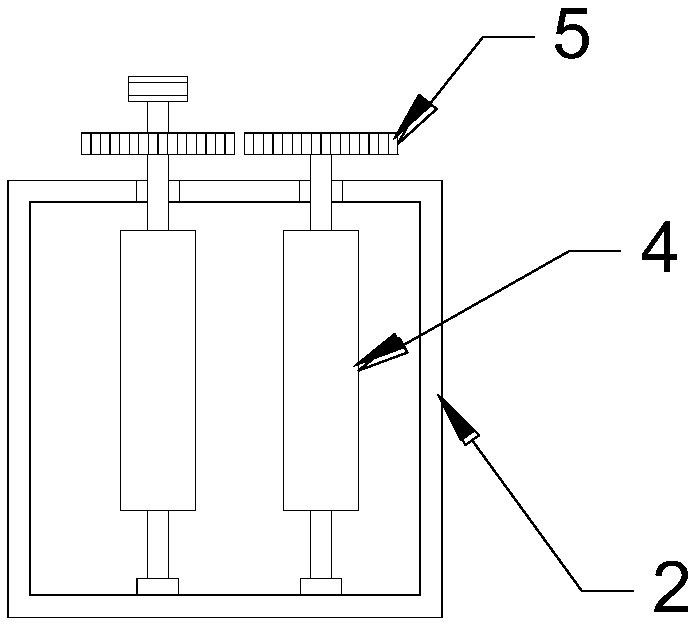

[0021] see Figure 1~2 , in an embodiment of the present invention, a pretreatment device for solid waste before transportation, including a crushing cylinder 1, a crushing bucket 2 and a dehydration cylinder 14; the crushing cylinder 1 is a vertical cylindrical structure, and the upper end of the right side of the crushing cylinder 1 There is a crushing bucket 2 in communication, and a feeding hopper 3 is connected above the crushing bucket 2, and garbage is put into the crushing bucket 2 from the feeding hopper 3; the crushing bucket 2 is provided with front and back symmetrical extrusion rollers 4, and the extrusion rollers 4 and the crushing bucket 2. The inner wall is rotationally connected, and the squeeze rollers 4 are connected by a transmission gear set 5, so that the squeeze rollers 4 rotate in opposite directions, and the rubbish is initially squeezed and crushed; the squeeze rollers 4 are connected with a vertical shaft through a transmission belt 6 7. The vertical...

Embodiment 2

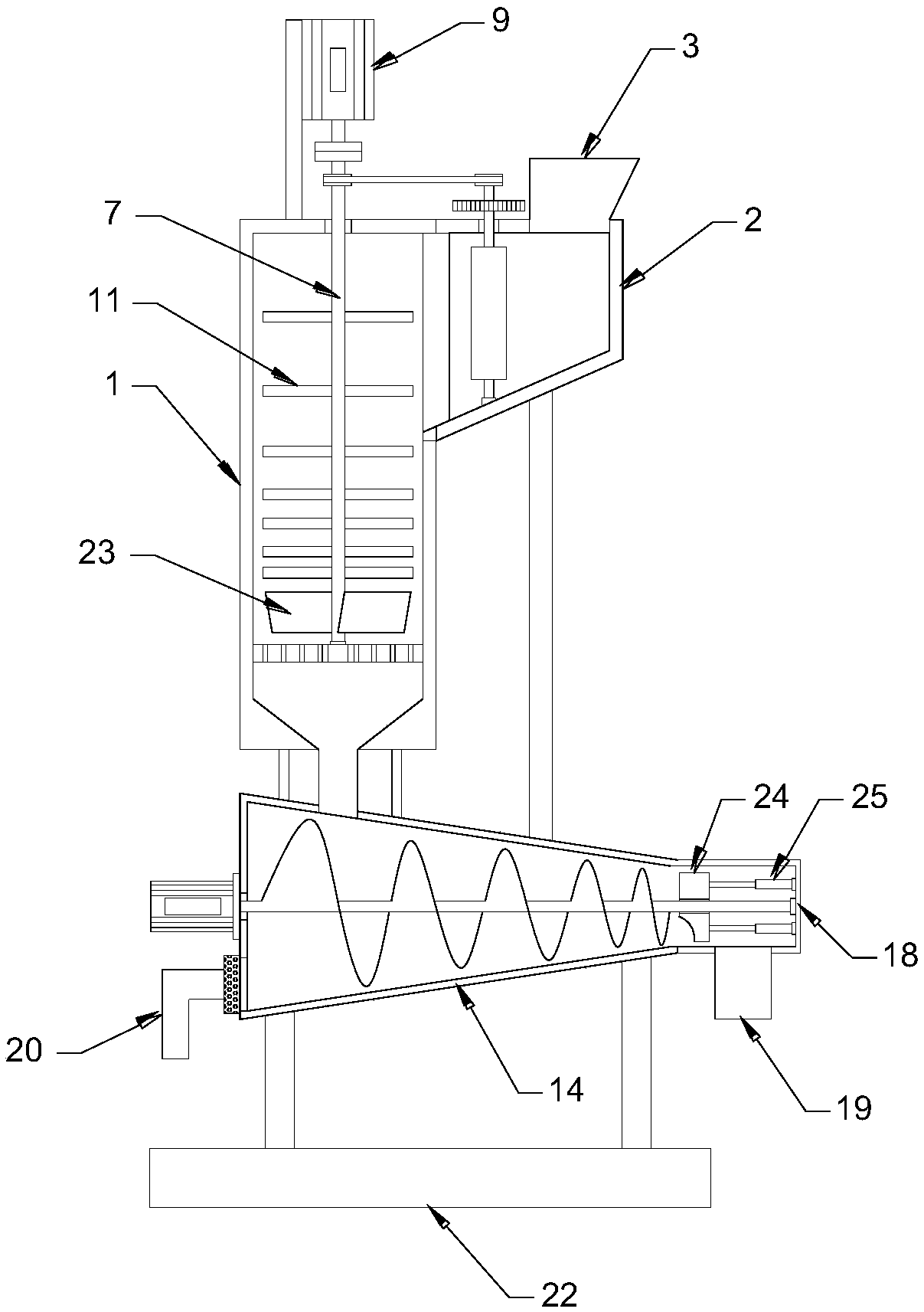

[0023] see image 3 and Figure 4 , The difference between this embodiment and Embodiment 1 is that: above the sieve plate 12, there are scrapers 23 distributed in a circle, the scrapers 23 are fixedly connected with the vertical shaft 7, the scrapers 23 are arranged obliquely, and the vertical shaft 7 Drive the scraper 23 to rotate, raise the solid waste accumulated on the sieve plate 12, avoid the clogging of the sieve plate 12 and improve the crushing efficiency; the horizontal pipe 18 is nested with a moving block 24, which is set on the horizontal axis 15 and is slidably connected with the horizontal shaft 15, the moving block 24 is connected with the inner wall of the horizontal pipe 18 through the spring telescopic rod 25, when the screw extrusion blade 16 pushes the garbage particles to move to the right, the particles squeeze the moving block 24, and the spring telescopic rod 25 Compressed to improve the effect of extrusion dehydration, when the moving block 24 moves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com