A kind of spin-coating equipment for lens

A lens and equipment technology, applied in the field of spin coating equipment for lenses, can solve the problems of large waste of strengthening liquid, high cost and high equipment requirements, and achieve the effects of avoiding qualitative change, effectively collecting and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

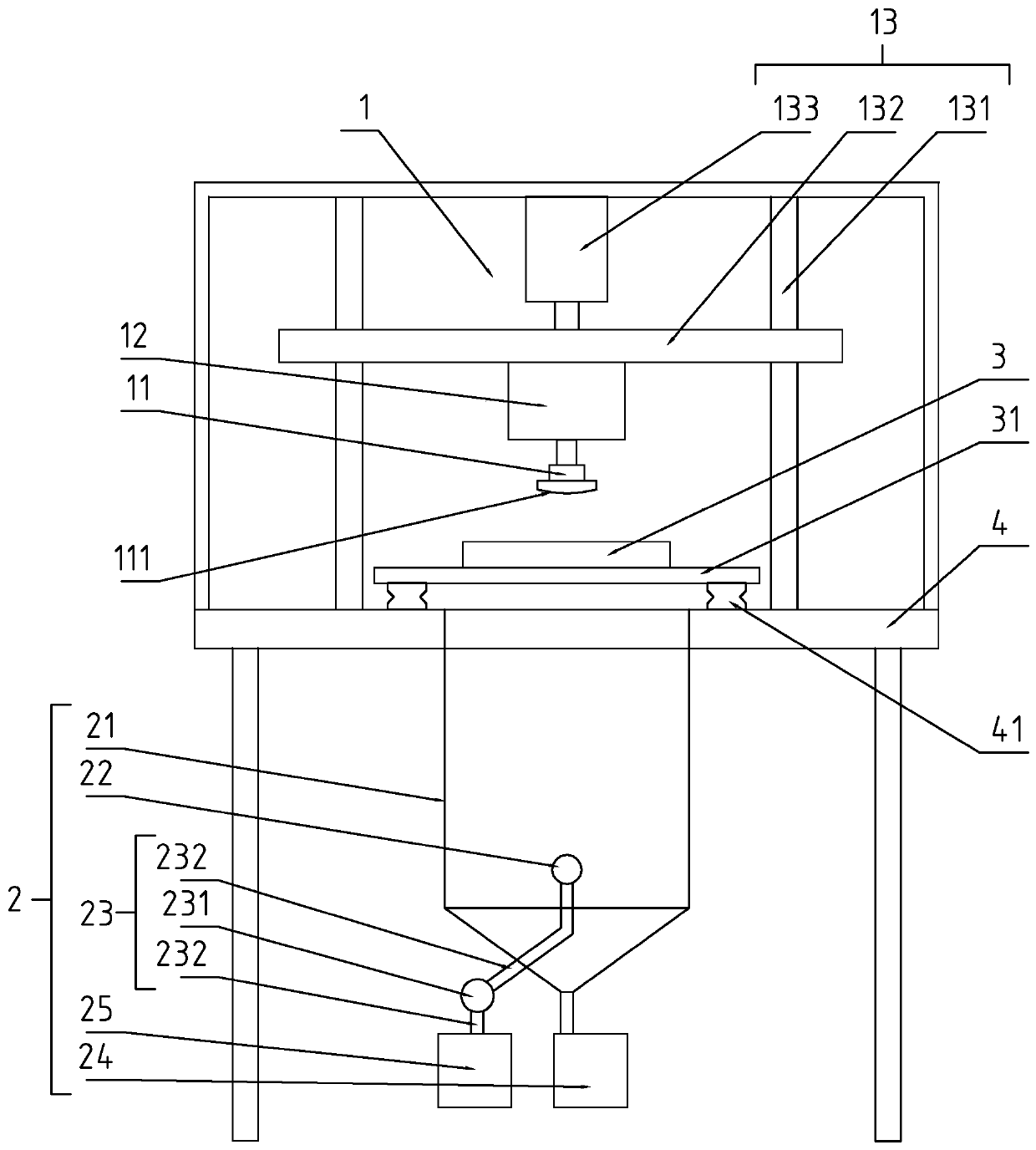

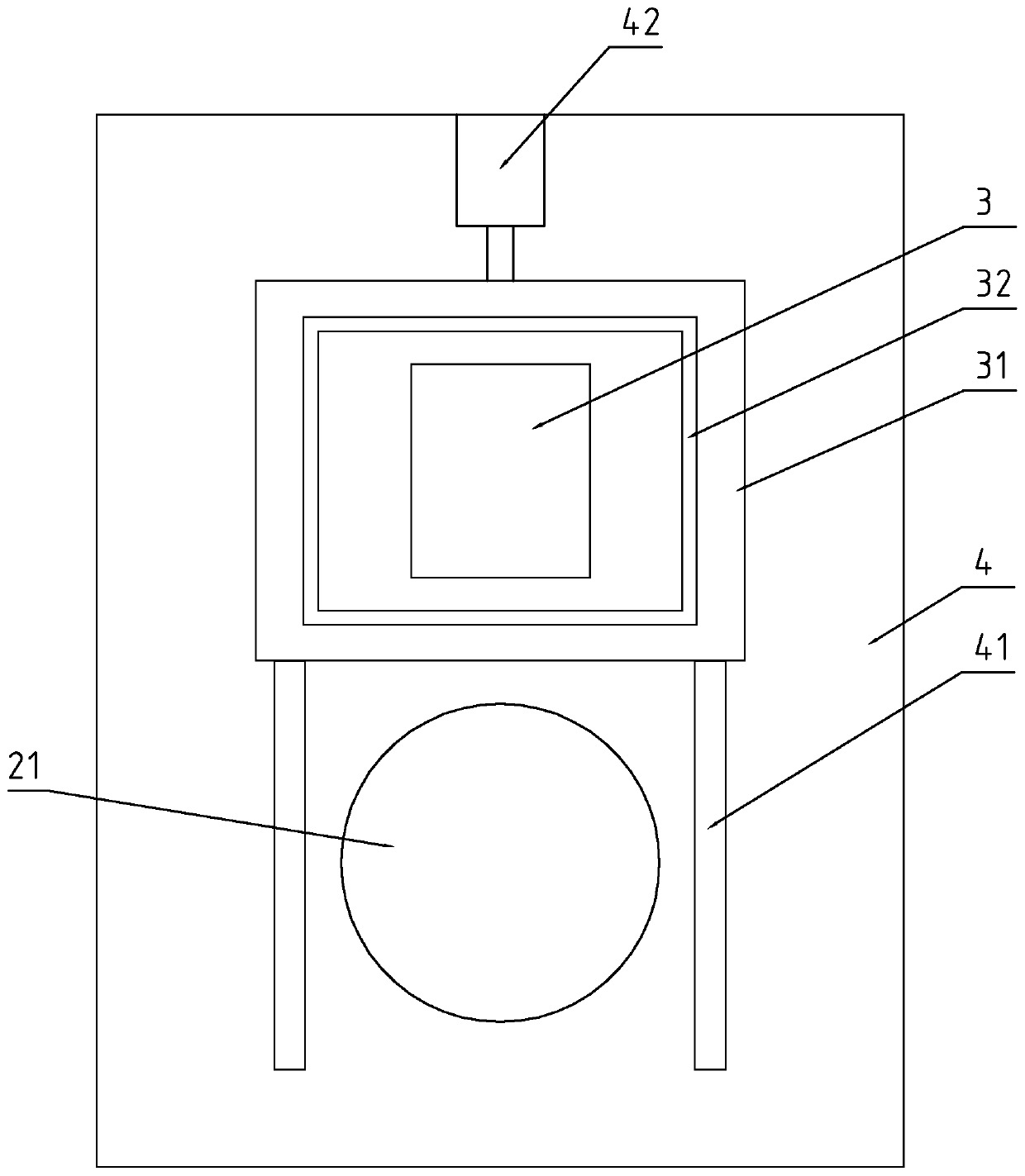

[0019] refer to figure 1 , 2 As shown, a spin coating equipment for lenses, including a manipulator 1 for fixing the lens, a feeding mechanism 2 for coating the strengthening liquid on the lens, and a UV curing lamp for irradiating and curing the strengthening liquid 3. The feeding mechanism 2 includes a recovery cylinder 21 for receiving the enhancement liquid that is centrifugally thrown out from the lens, a spray head 22 located in the recovery cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com