Device for collecting underwater wet method welding arc ambient gas and use method thereof

A surrounding gas and wet welding technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems that are not conducive to gas collection, and achieve the effect of simple structure, small size and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention. The methods used in the present invention are conventional production methods unless otherwise specified; the raw materials used are conventional commercially available products unless otherwise specified.

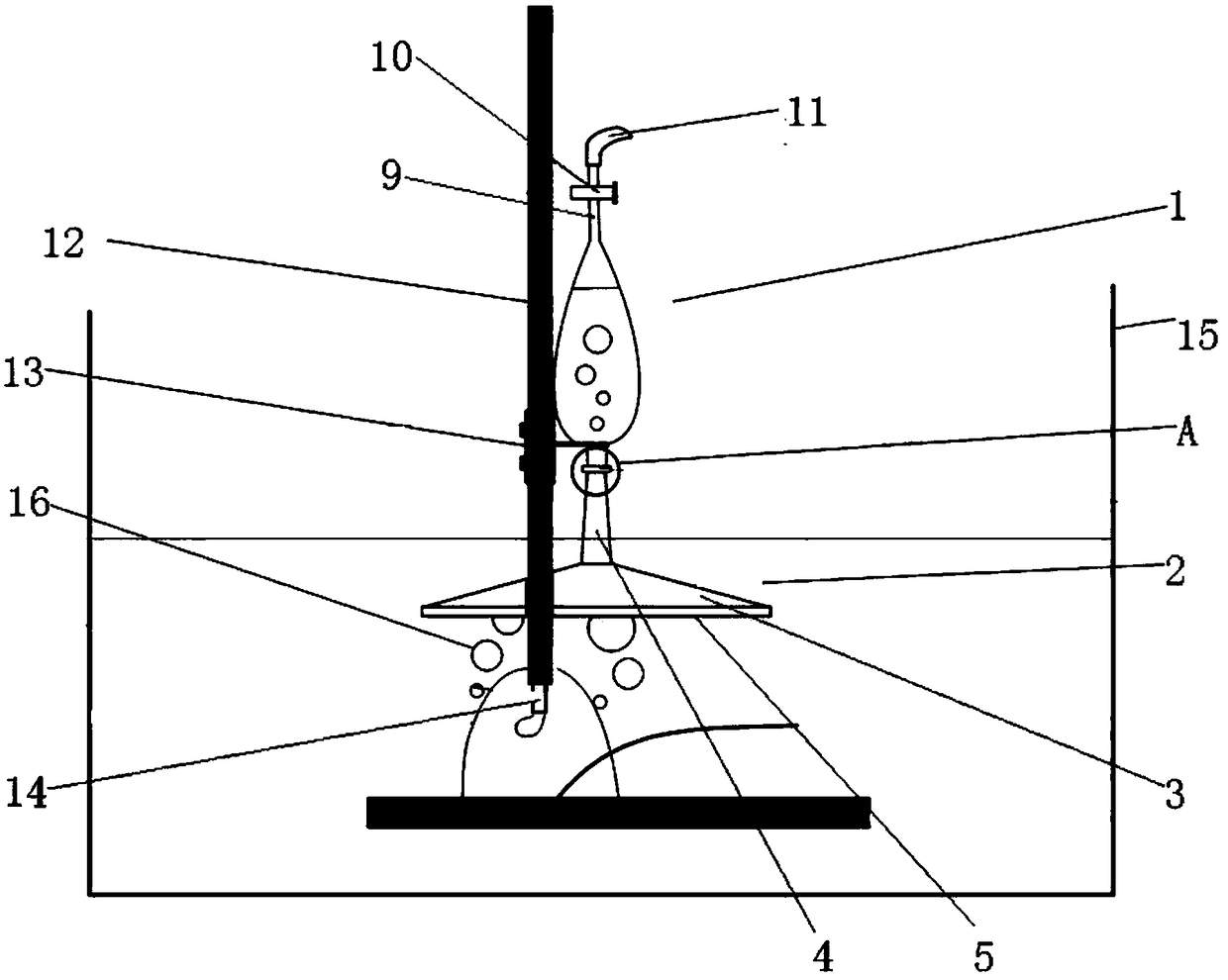

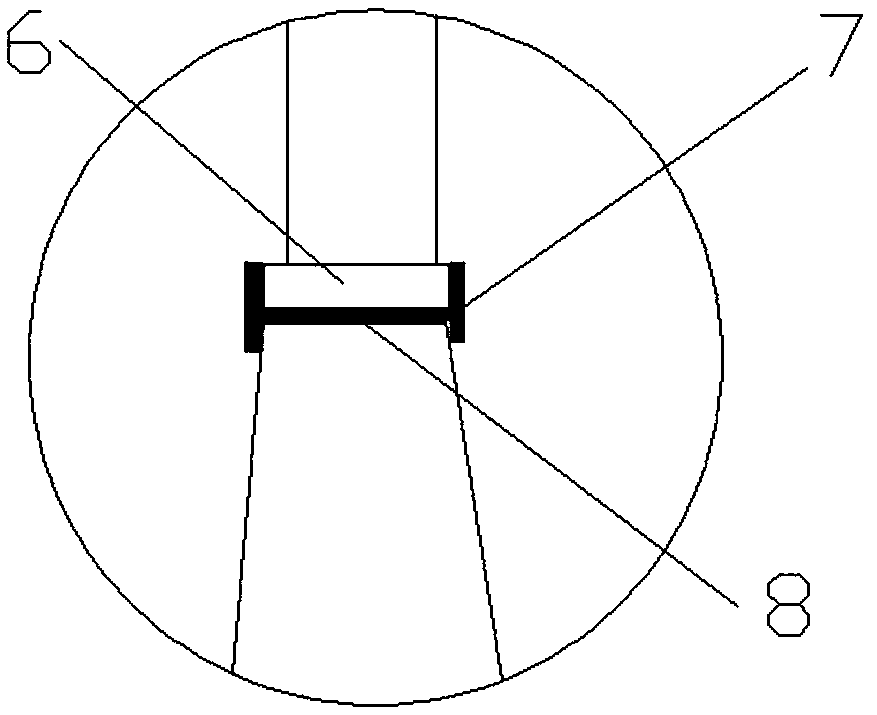

[0026] Such as figure 1 As shown, a device for collecting gas around the underwater wet welding arc is provided with a gas storage device 1 and an air intake device 2 that are connected up and down and are sealed and fixed. The air intake device 2 is an inverted funnel-shaped structure, which includes a funnel Body 3 and funnel neck 4, funnel body 3 and funnel neck 4 are connected as an integral structure; Funnel body 3 is the vertebral body structure that upper end and lower end open respectively, and the diameter of lower end opening is greater than the diameter of upper end ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com