A universal welding system for flower baskets

A welding system and flower basket technology, which is applied in the field of general welding system for flower baskets, can solve the problems of not being able to process flower baskets and satisfy customers, and achieve the effects of reducing jams, improving production efficiency, and reducing damage rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

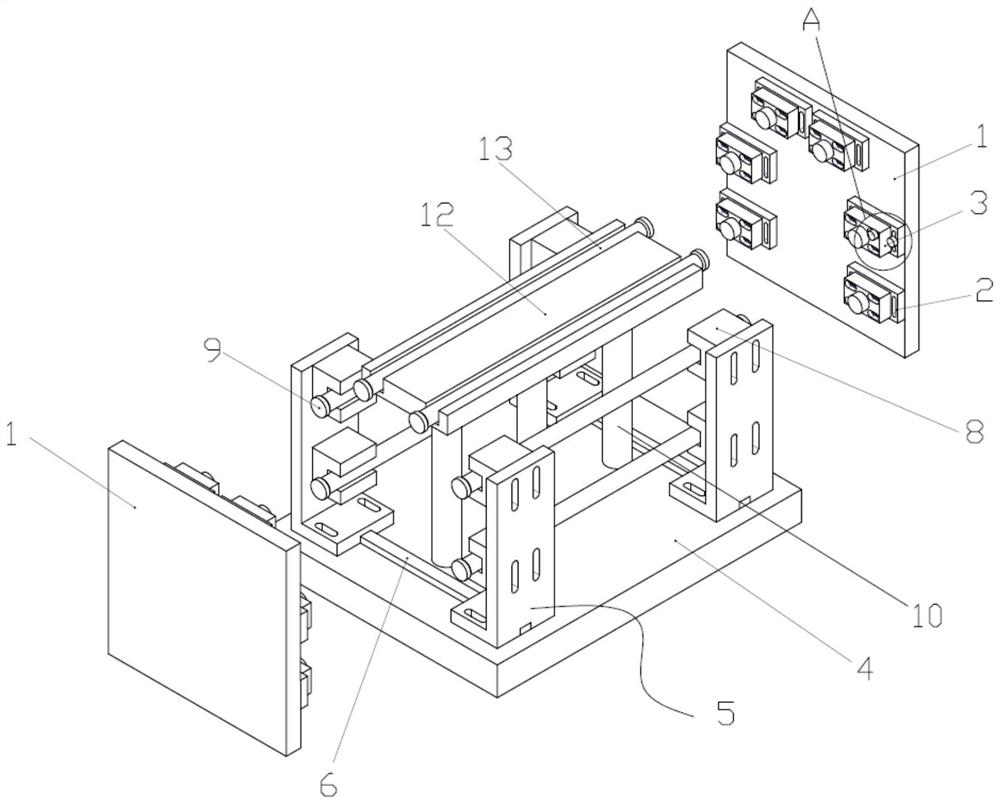

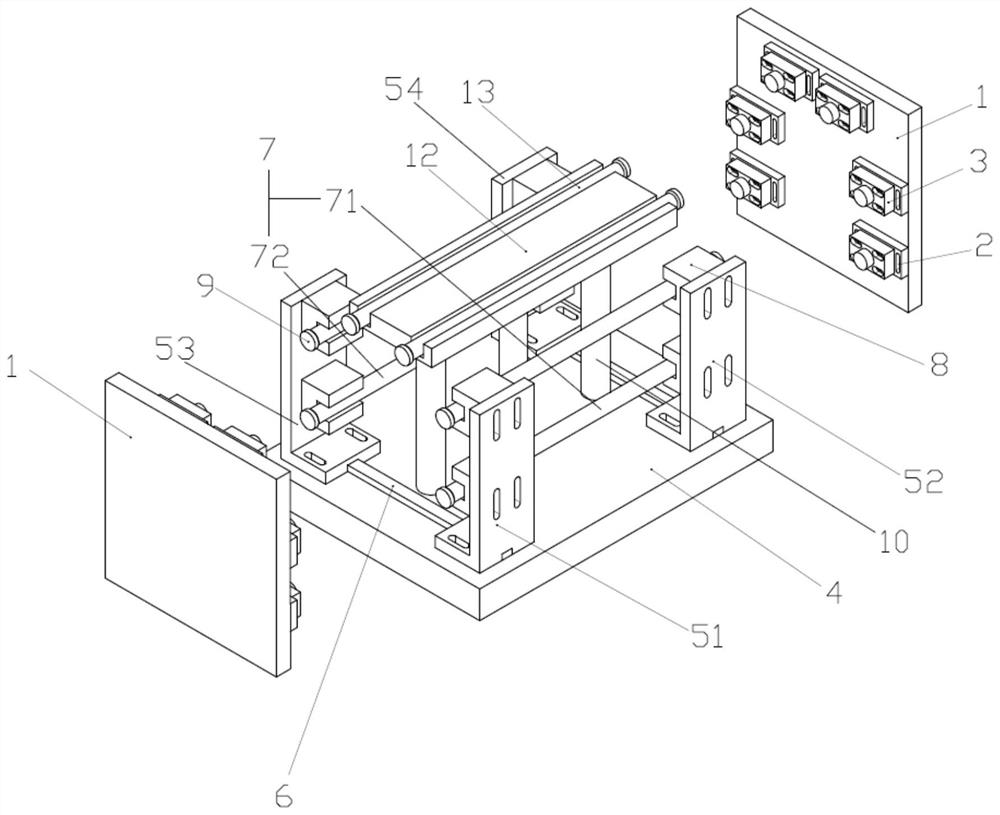

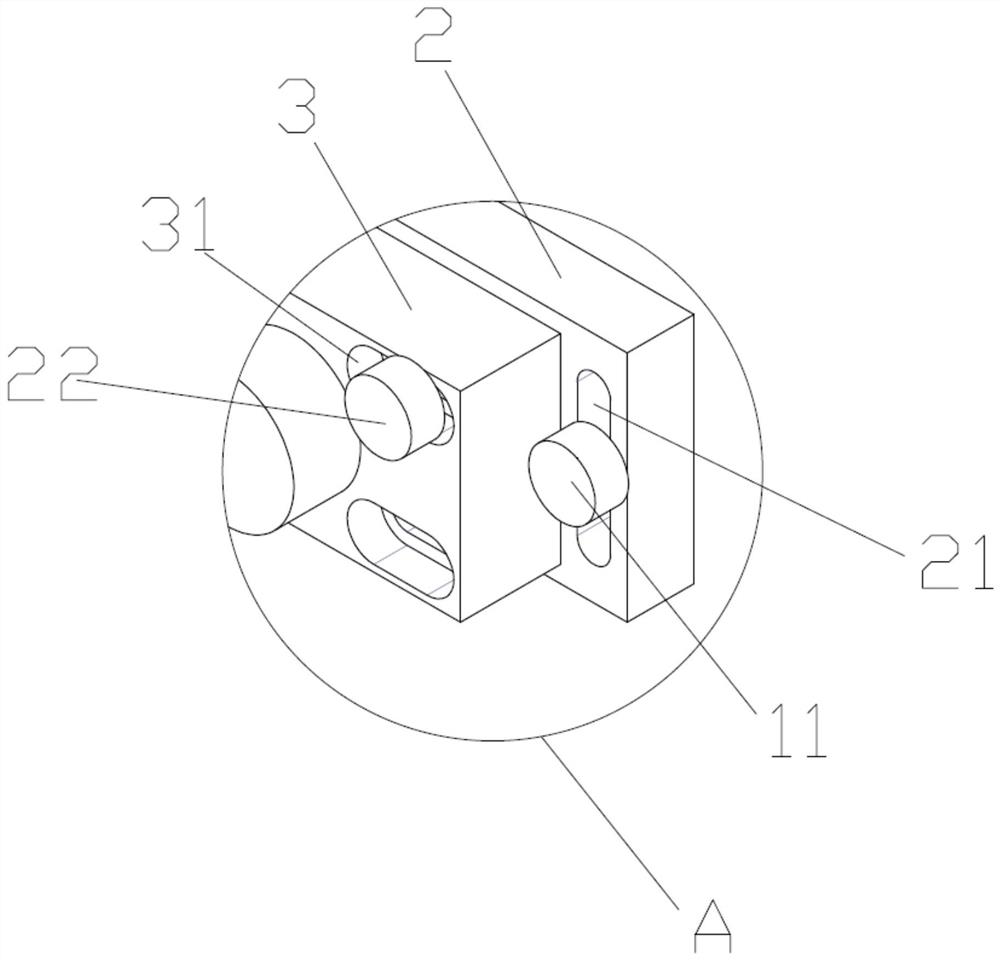

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] A universal welding system for flower baskets, including base plate 1, heating point base 2, heating point 3, gear bar base plate 4, gear plate base plate group 5, gear bar guide block 6, side gear bar group 7, gear bar positioning block 8, heat Melting mechanism 9, the base plate 1 is slidingly matched with the heating point base 2, the heating point 3 is arranged on the heating point base 2, the gear plate base plate group 5 is installed on the gear bar base plate 4, the gear plate base plate group 5 includes the first The tooth plate base plate 51, the second tooth plate base plate 52, the third tooth plate base plate 53 and the fourth tooth plate base plate 54, the first tooth plate base plate 51 and the third tooth plate base plate 53 are connected by the gear bar guide block 6, the first tooth plate base plate The rack base 51, the second gear ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com