Novel non-standard automatic butt welding machine

A welding machine and non-standard technology, which is applied in the field of new non-standard automatic welding machines, can solve the problems of low work efficiency, deformation of welded parts, inability to clean smoke and dust, etc., and achieve the effect of improving work efficiency and facilitating heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

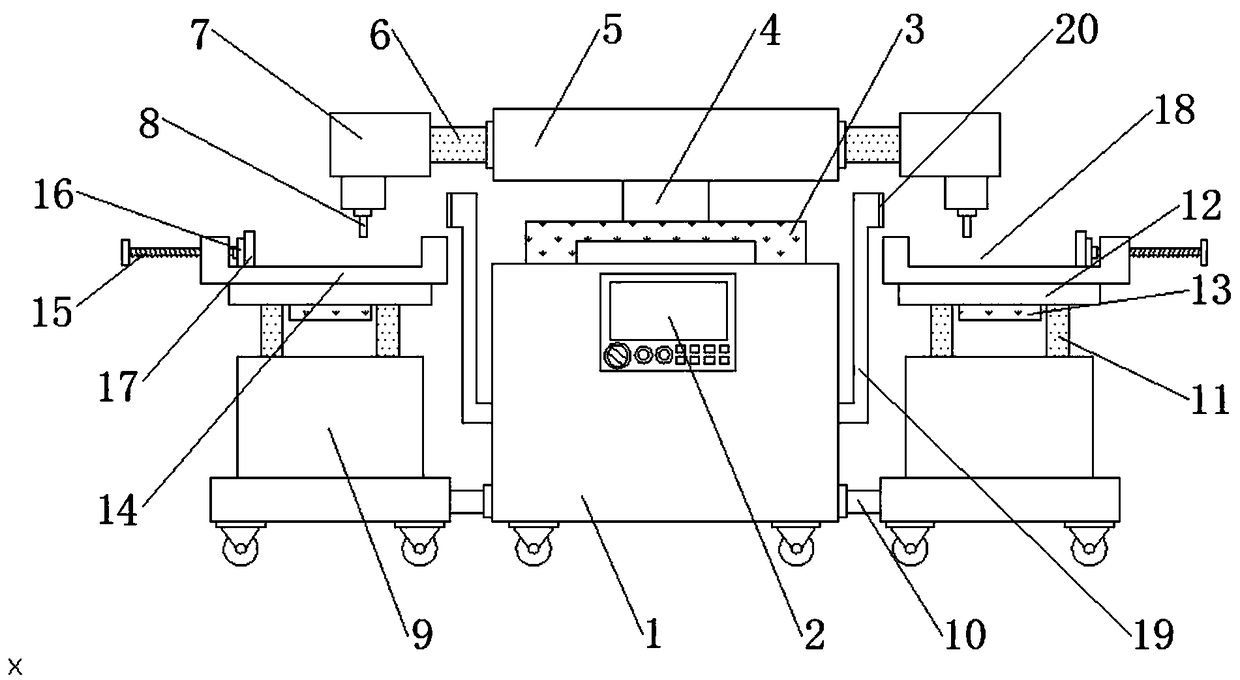

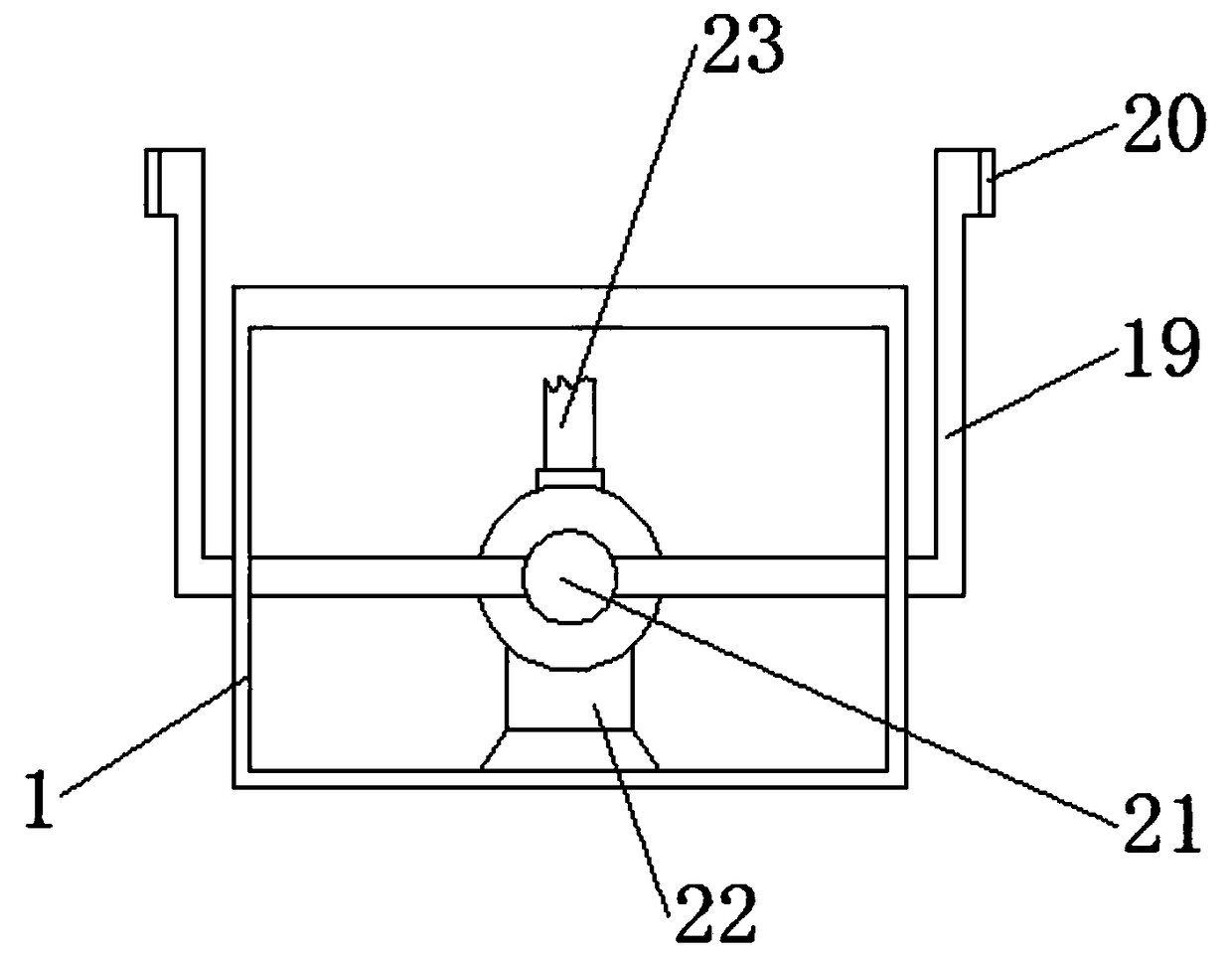

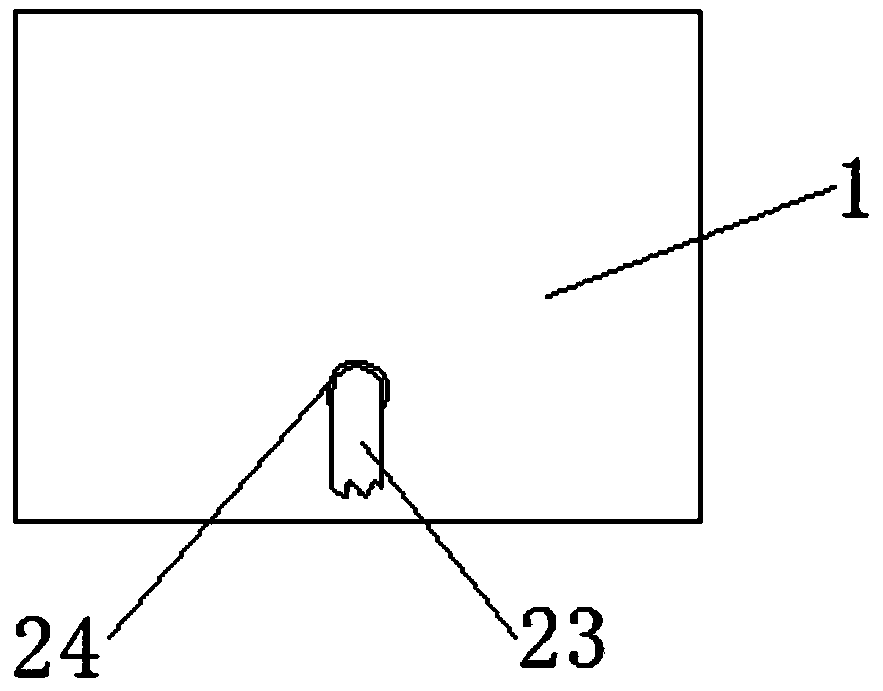

[0025] Example: refer to Figure 1-3 , the present invention provides a technical solution, a new type of non-standard automatic welding machine, including a first fixed seat 1, the front surface of the first fixed seat 1 is provided with a MAM-100 control panel 2, and the first fixed seat 1 The top is connected with a support frame 3, the top of the support frame 3 is connected with a fixed rod 4, the top of the fixed rod 4 is connected with a fixed frame 5, the two ends of the fixed frame 5 are connected with a first hydraulic telescopic rod 6, and the first hydraulic telescopic rod One end of 6 is connected with welding torch holder 7, and the bottom of welding torch holder 7 is provided with welding torch head 8, and the both sides of first holder 1 are all provided with second holder 9 below welding torch head 8, and the bottom of second holder 9 A limit block 10 is arranged on one side close to the first fixed seat 1, and a second hydraulic telescopic rod 11 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com