Screw chip removal system for carving machine

A technology of engraving machine and screw, applied in the field of engraving machine, can solve the problems of high manufacturing cost, no need to separate and adjust the oil chips, and achieve the effect of reducing the volume of the oil tank, reducing the distribution distance of the screen holes, and reducing the manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

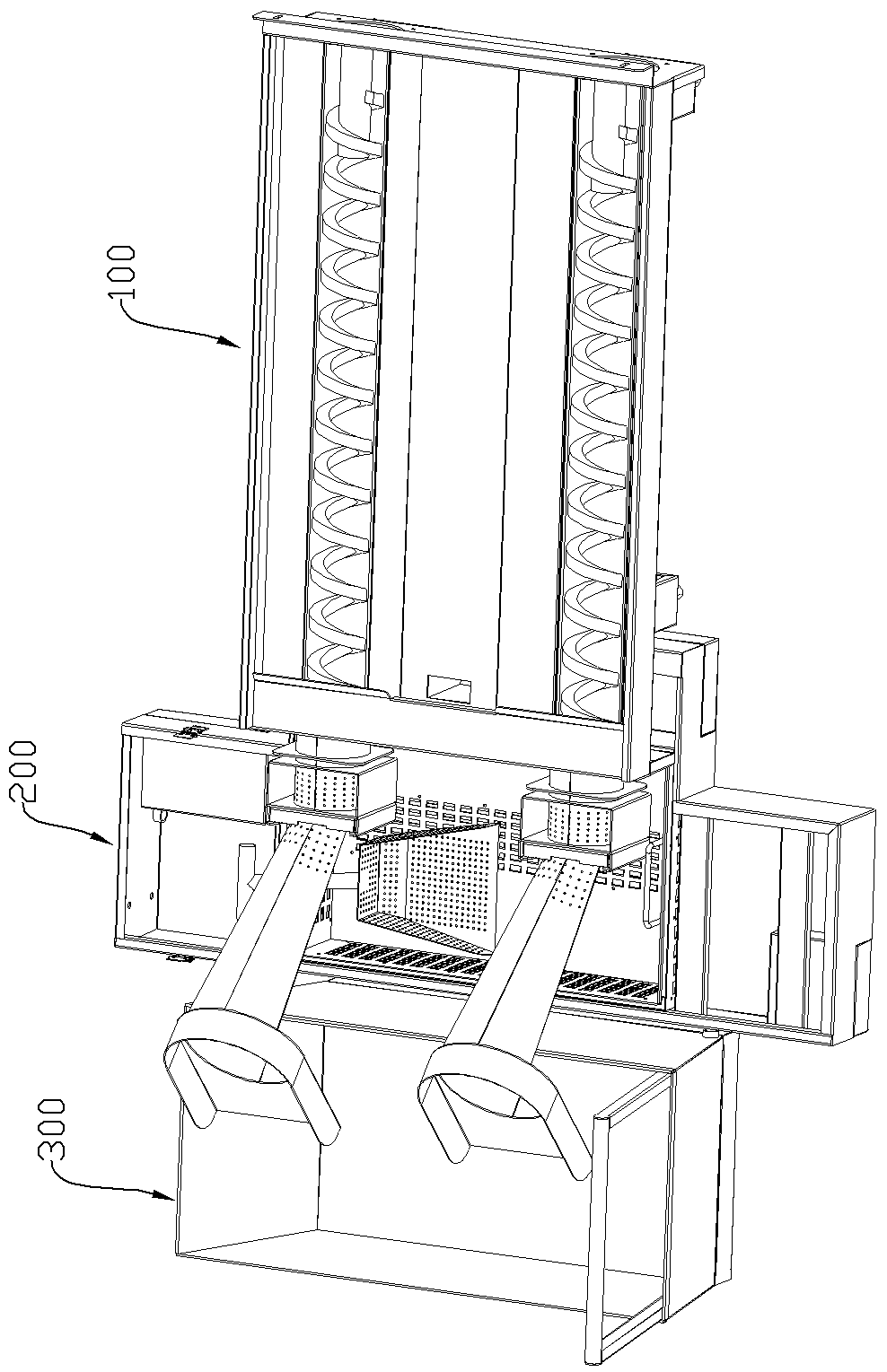

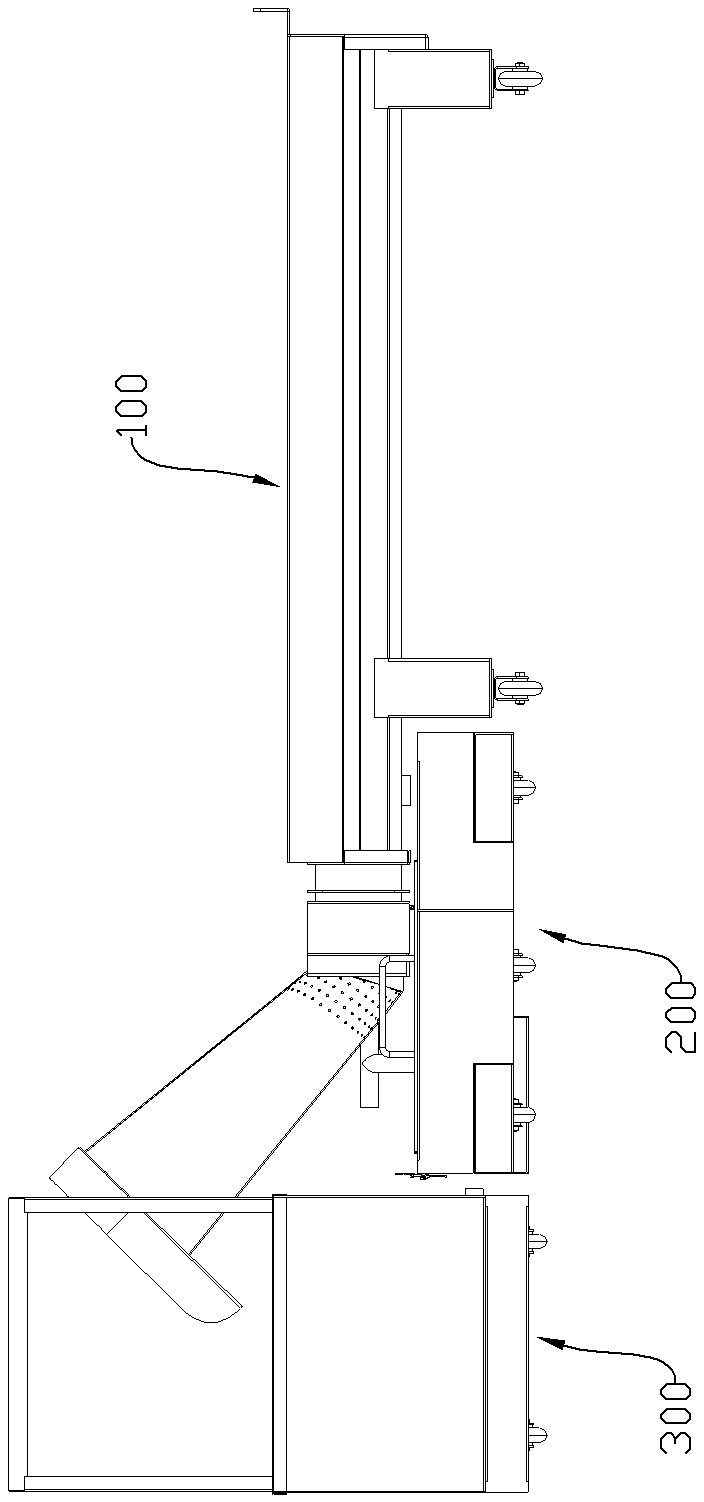

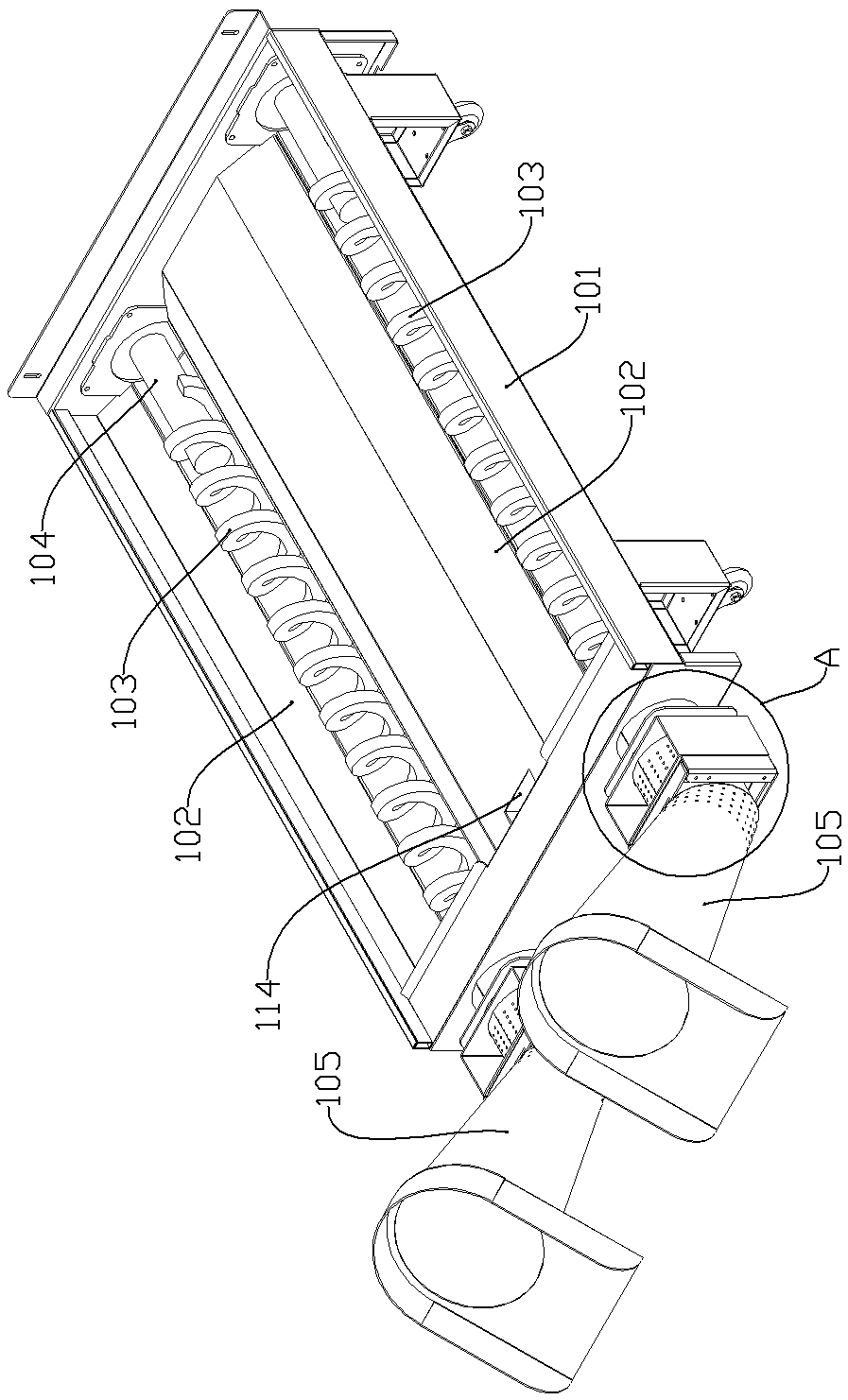

[0020] like Figure 1~Figure 7 As shown, the screw chip removal system for Jingdiao machine includes a screw chip removal device 100, an oil tank 200 and a waste chip trolley 300. The fuel tank 200, the waste chip trolley 300 and the screw chip removal device 100 are respectively equipped with rollers for easy movement. The body 101 of the chip removal device 100 is provided with a chip removal groove 102, the screw 103 is installed in the chip removal groove 102, the rods 104 at both ends of the screw 103 are respectively supported on the side wall of the body through bearings and driven by a motor, the chip removal groove 102 passes through The first connecting pipe 105 leads waste chips to the waste chip trolley 300. The tail end of the chip removal groove 102 is connected with a second connecting pipe 106. The second connecting pipe 106 is detachably connected with the first connecting pipe 105. There is a sieve hole 107, and the fuel tank 200 is located below the sieve ho...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap