Blade grinding machine steel belt unwinding temporary-storage device

A cache and steel belt technology, which is applied to the parts of grinding machine tools, grinding/polishing safety devices, grinding feed movement, etc., can solve the interruption of production continuity, the steel belt running out of the docking device, and the reduction of production efficiency and other problems, to achieve the effect of reducing friction, improving work efficiency and stabilizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

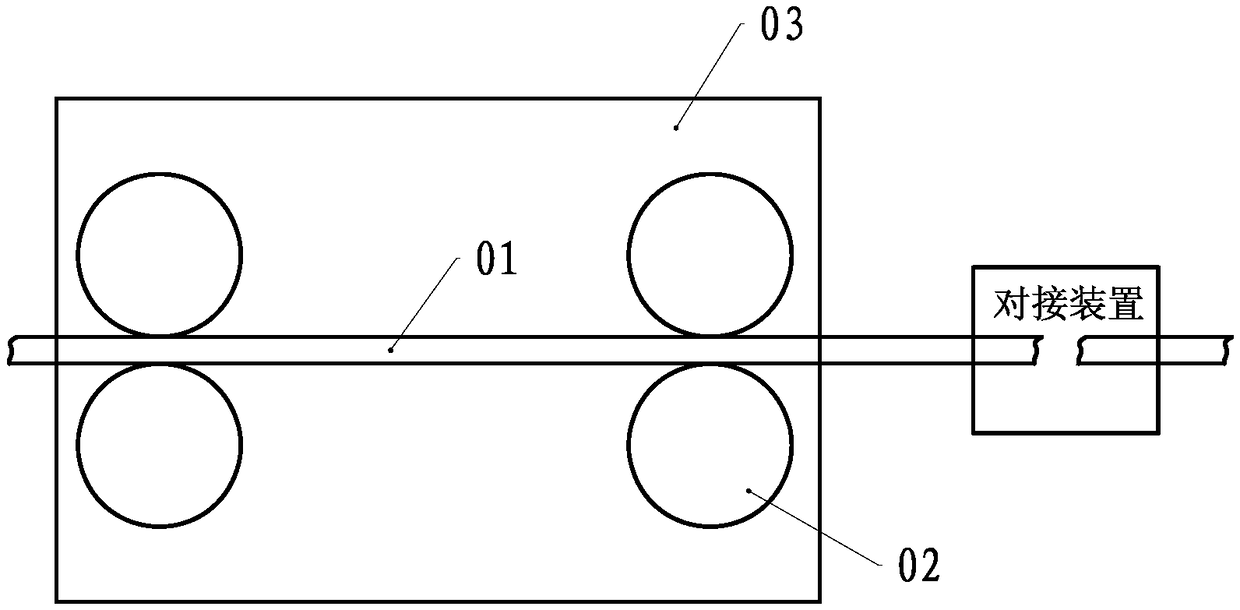

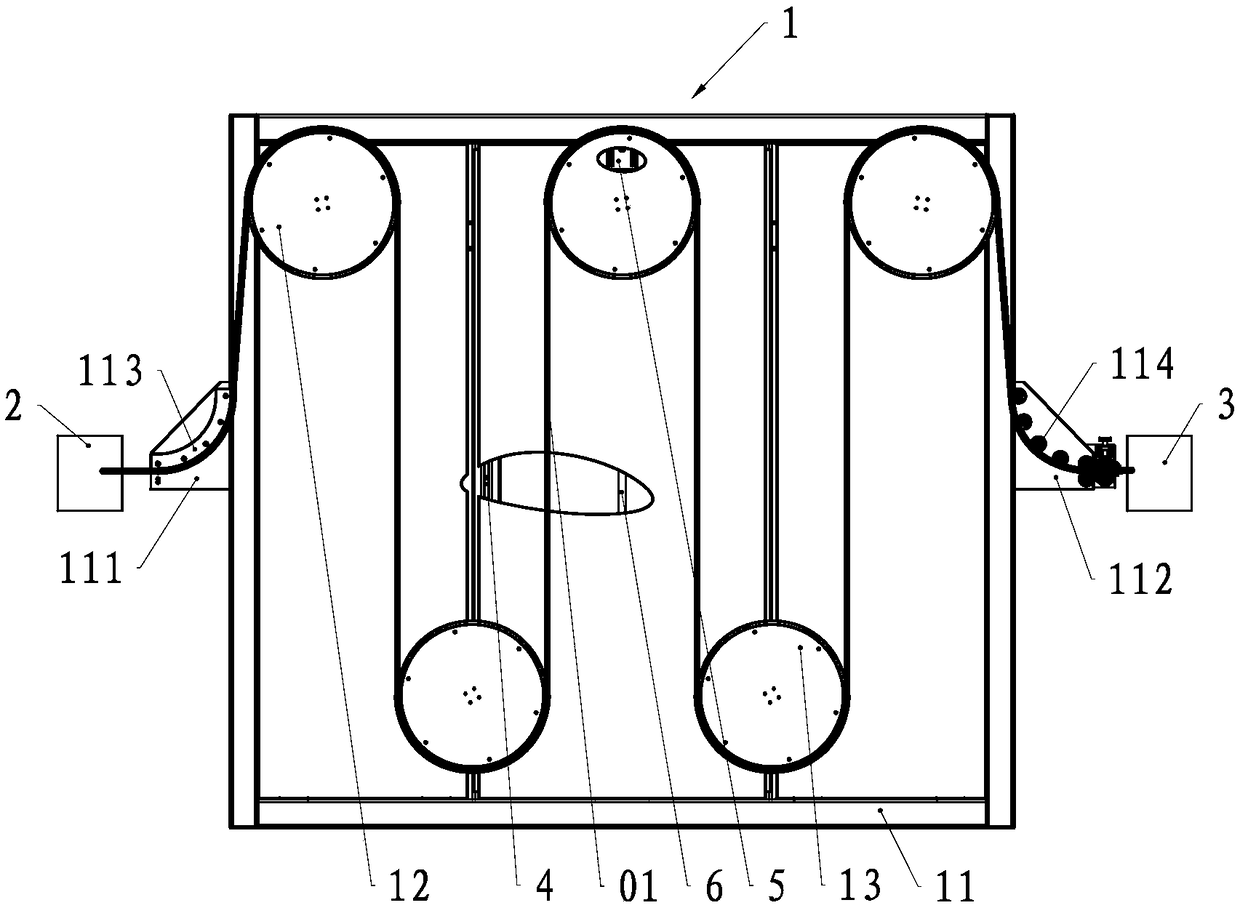

[0034] see figure 2 with image 3 , the present embodiment is applied to the steel belt discharge cache device on the blade grinder, which includes a cache table 1, a tractor 2 and a docking machine 3. The pulling machine 2 and the docking machine 3 are respectively arranged on two opposite sides of the buffer platform 1 . One end of the steel belt 01 is located in the pulling machine 2, the other end is located in the docking machine 3, and the middle part is wound in the buffer table 1 for buffering.

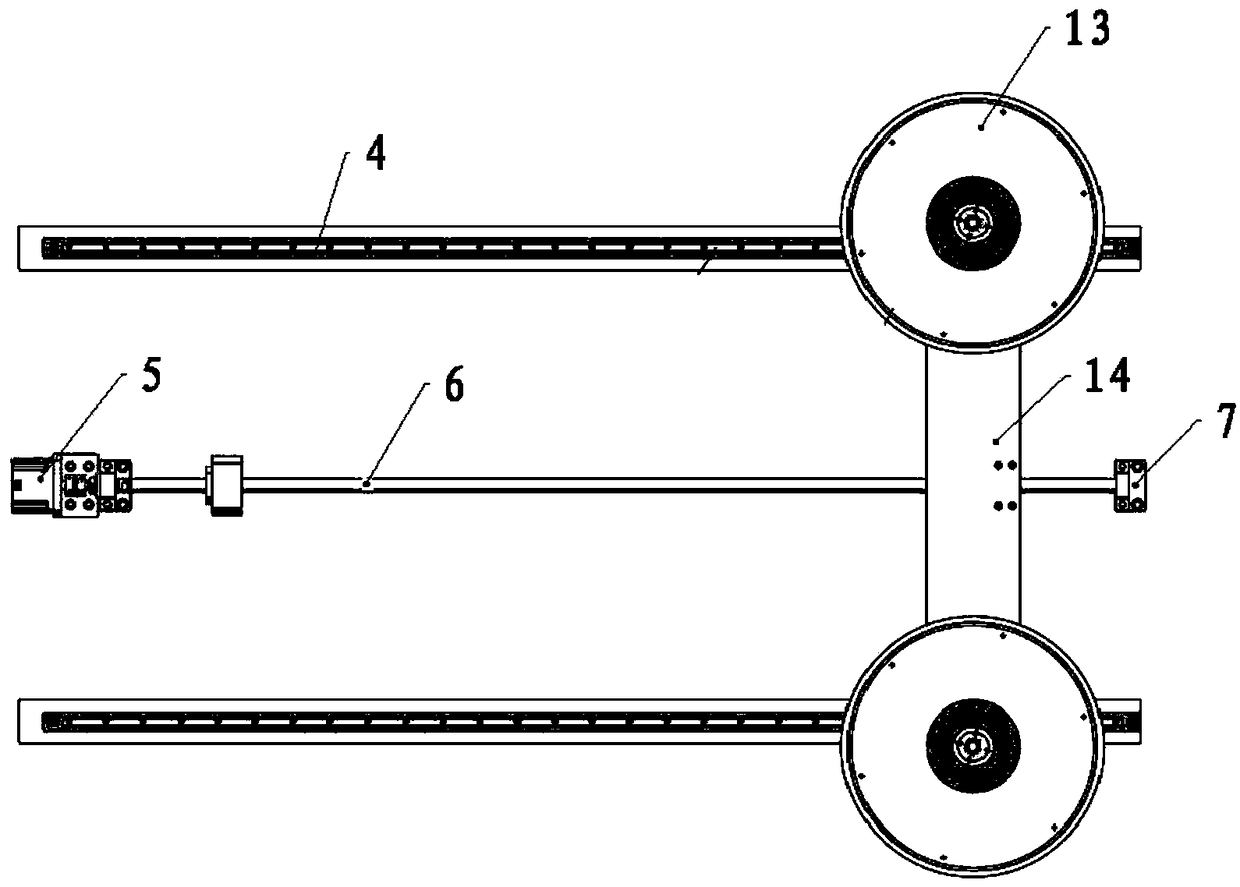

[0035] The buffer table 1 includes a base 11, a fixed plate set, a moving plate set and a driving mechanism. The set of fixed plates includes three fixed plates 12 arranged in a row along the edge of the base 11 at intervals, and a slide rail 4 is provided between two adjacent fixed plates 12 . The moving disk group includes moving disks 13 respectively mounted on two slide rails 4 . Both the fixed disk 12 and the moving disk 13 can freely rotate around the center. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com