Integrated grinding equipment for numerically controlled lathe

A CNC lathe, an integrated technology, applied in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of complex grinding operation and low precision, achieve simple operation, improve grinding and polishing accuracy, and facilitate grinding and polishing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

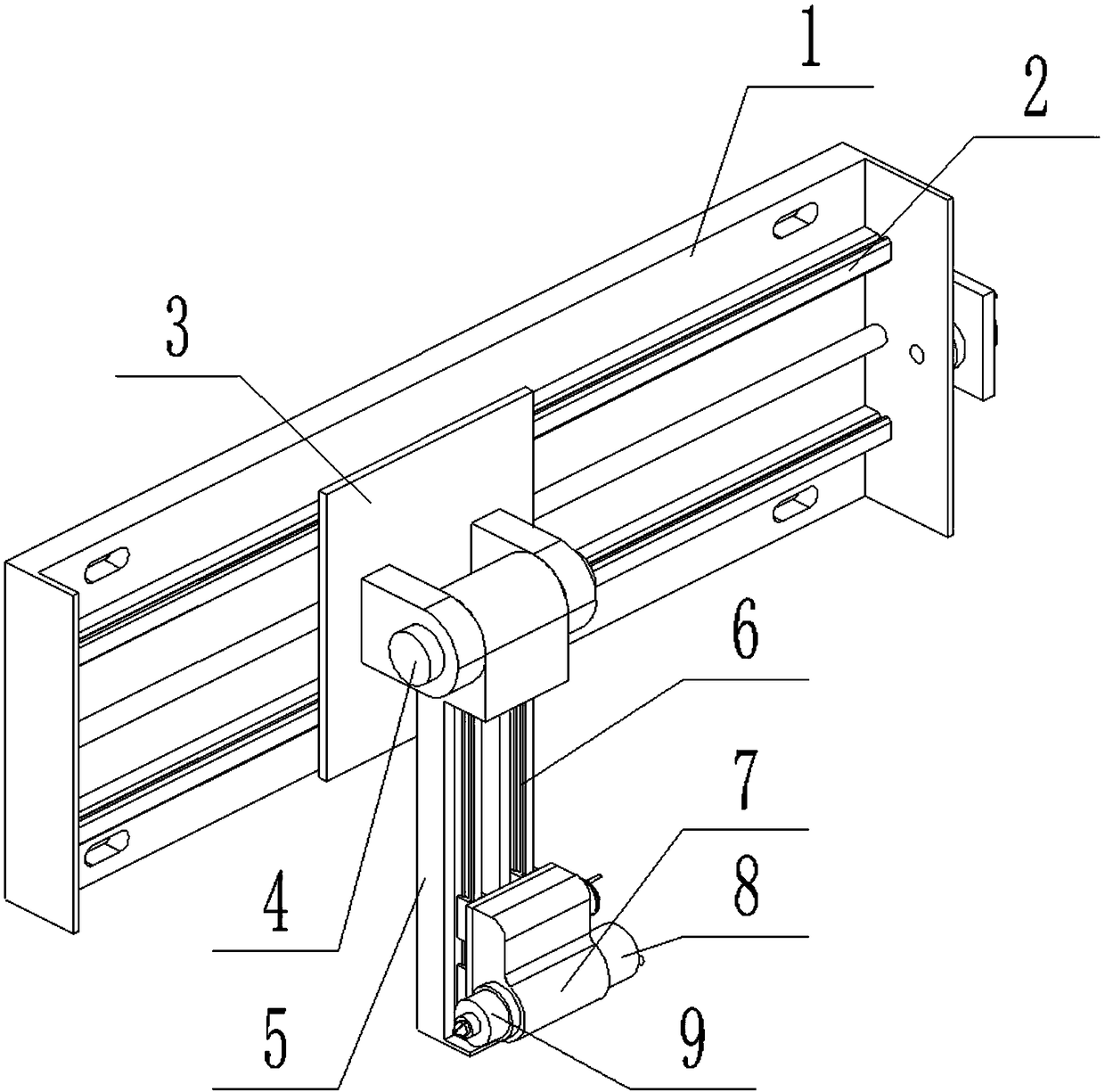

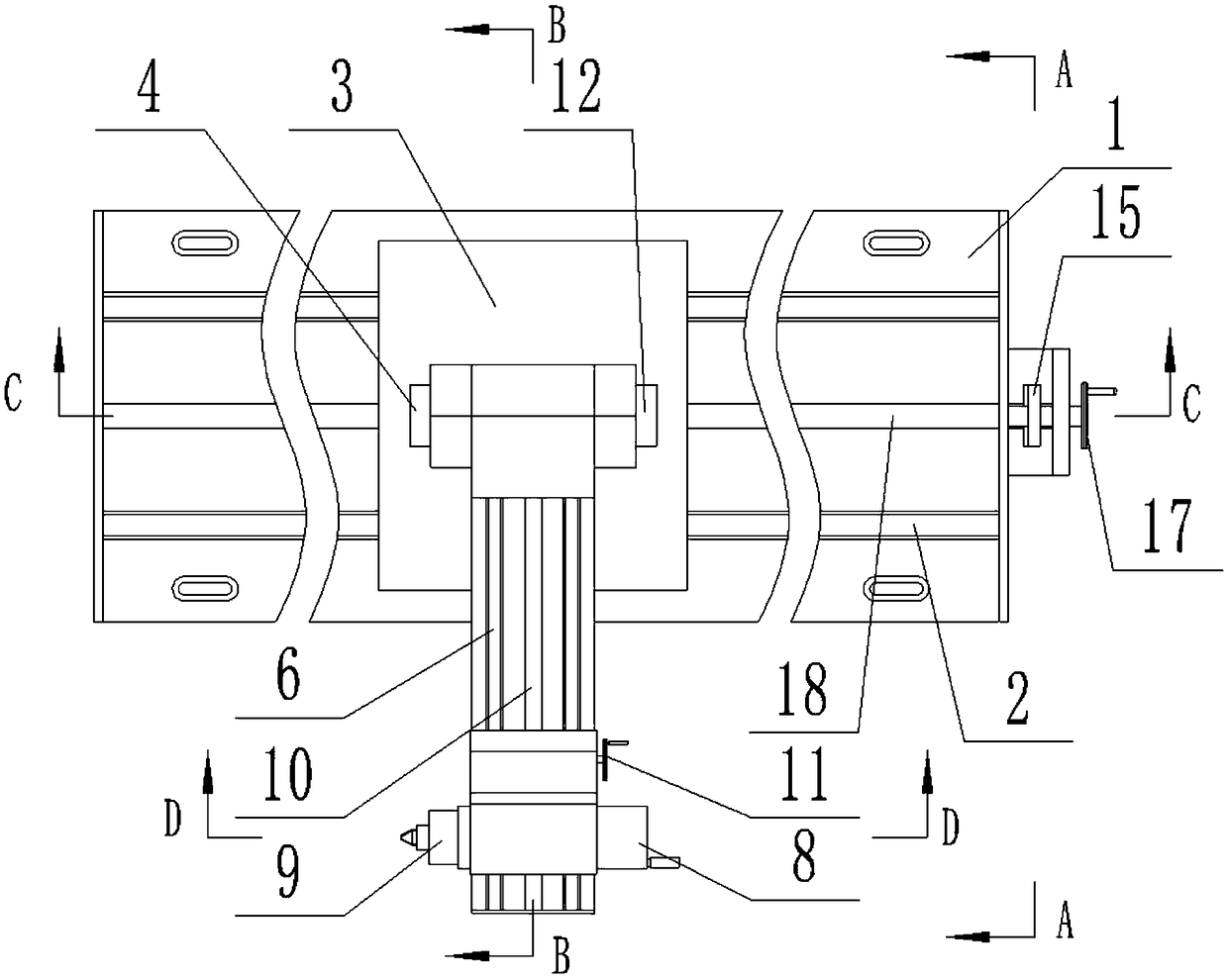

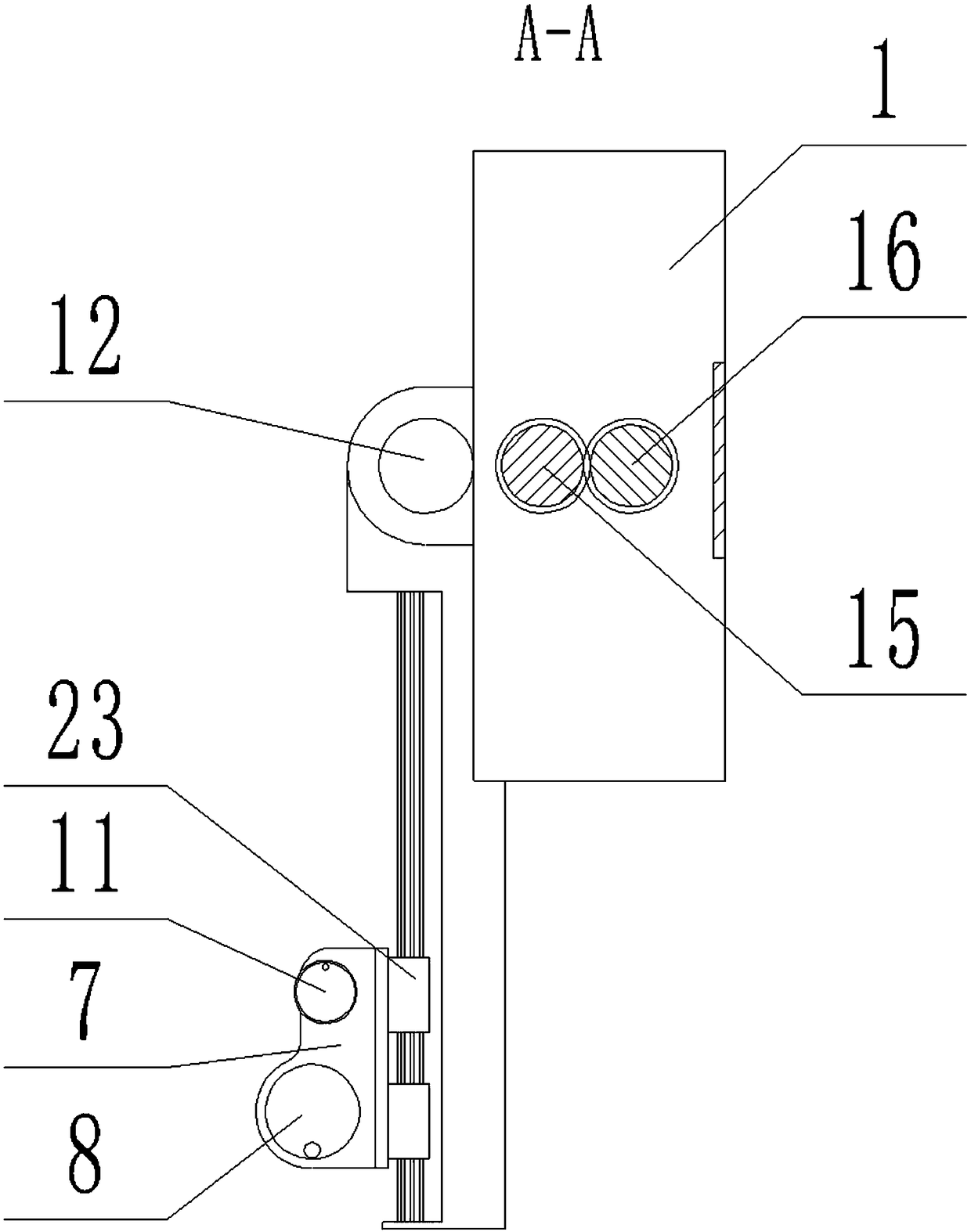

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033] The present invention provides an integrated grinding equipment for CNC lathes, including a base 1, a horizontal rail 2, a horizontal sliding table 3, a rotating central axis 4, a chute 0401, a threaded hole 0402, a vertical base 5, and locking teeth Slot 0501, rotating light hole 0502, vertical guide rail 6, vertical slide table 7, hand telescopic barrel 8, grinding electric spindle 9, rack 10, vertical sliding hand wheel 11, steering lock nut 12, lock Block 13, spring 14, transverse driving gear 15, transverse driven gear 16, transverse handwheel 17, transverse leading screw 18, transverse nut 19, transverse slide block 20, vertical driving gear 21, vertical driven gear 22 and vertical to the slider 23; the front end of the base 1 is fixedly connected with two groups of said transverse square rails 2; each group of said transverse square rails 2 is slidably connected with two groups of said transverse sliders ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com