Method for reliably delivering printing material and printing machine for implementing same

A technology for printing materials and printing machines, applied in printing machines, general parts of printing machinery, printing and other directions, can solve sensitive, expensive, slow and other problems, and achieve the effect of reliable placement and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

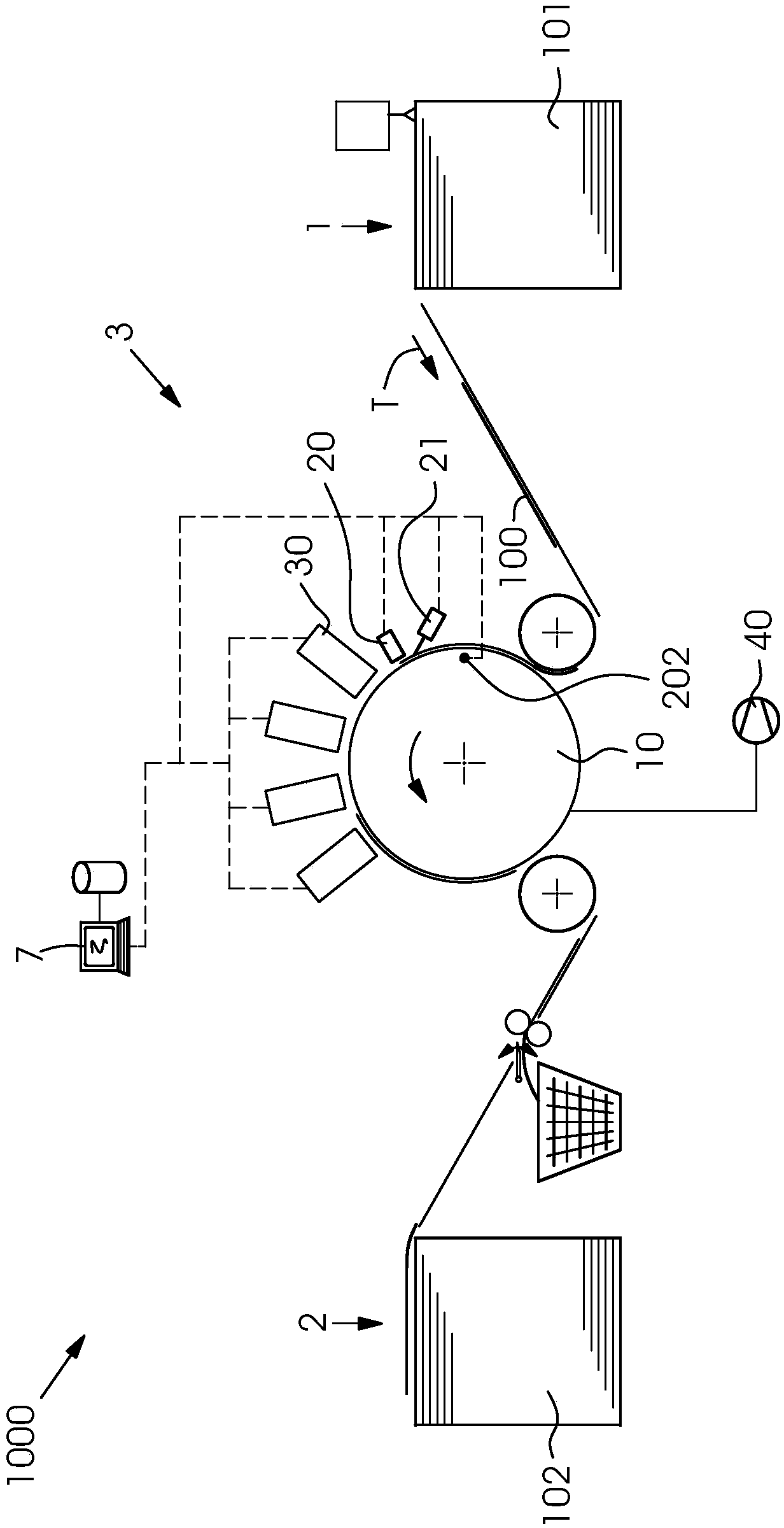

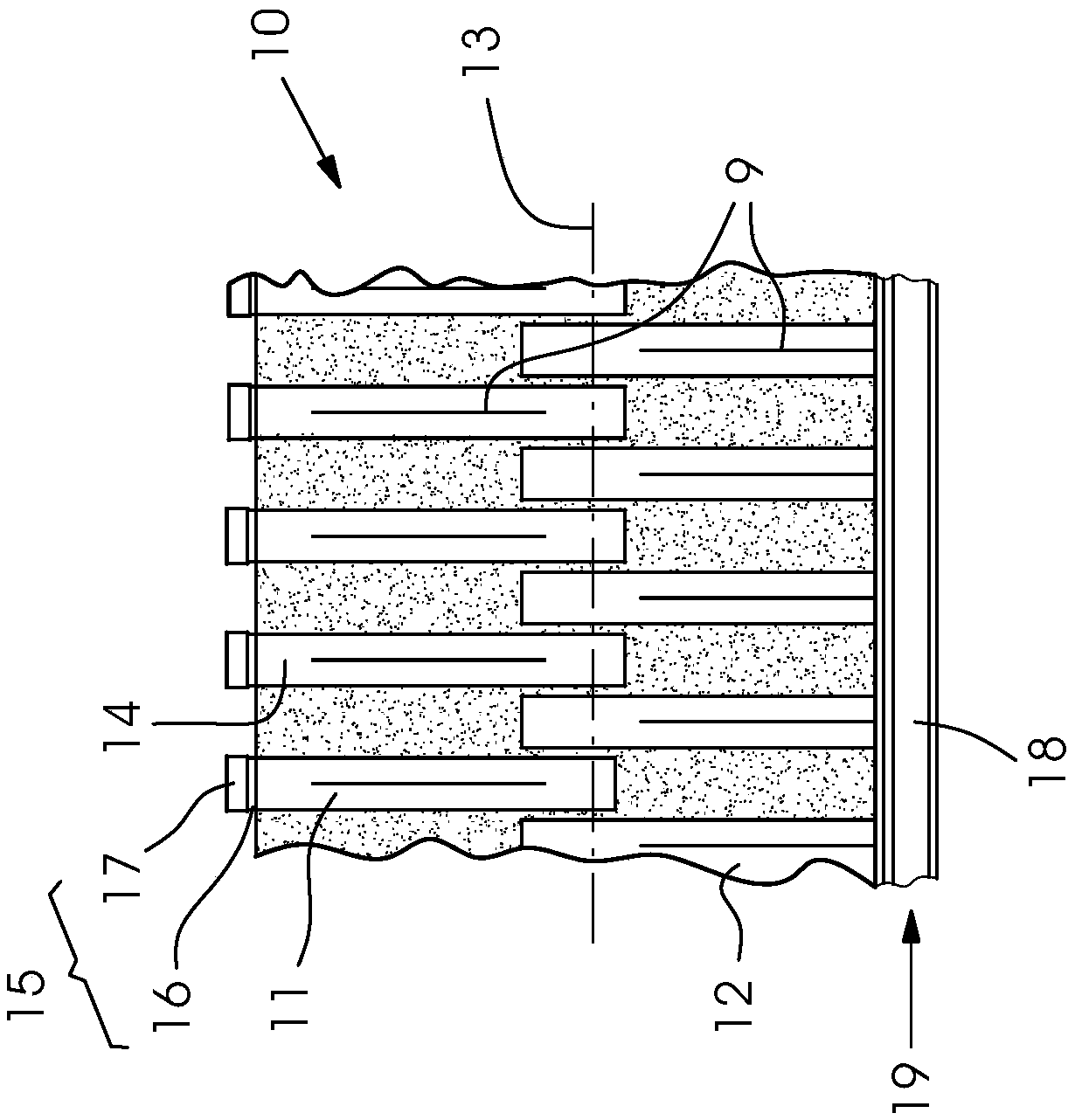

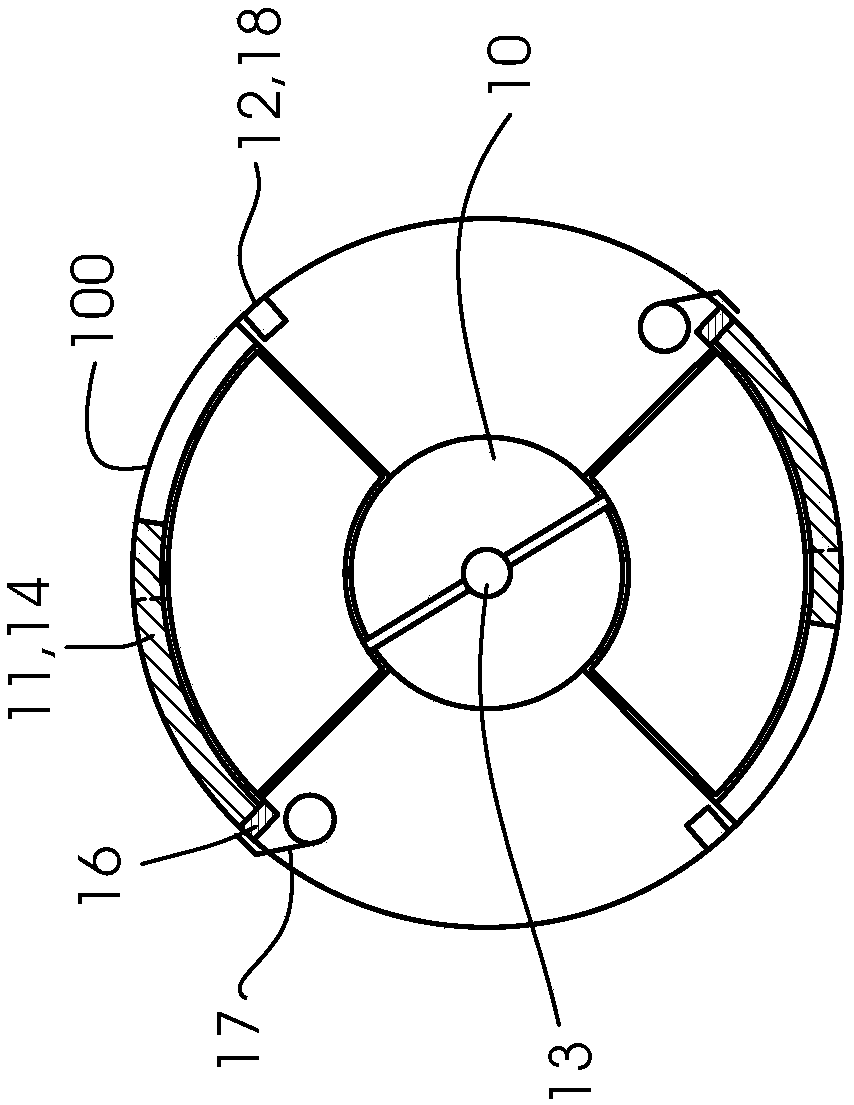

[0028] figure 1 A digital printing press 1000 for printing on sheets 100 is shown. The digital printing machine 1000 has a digital printing station 3 with a plurality of inkjet printing strips 30 arranged one behind the other in the conveying direction T, the inkjet printing strips 30 having inkjet printing strips 30 arranged parallel to one another. printing head. The sheets 100 from a feeder stack 101 in the sheet feeder 1 are transported in a transport direction T to the digital printing station 3 using transport means, not shown in detail, such as transport belts and transport rollers, for example. The transport of the sheet 100 through the digital printing station 3 is via jet cylinder 10 (see Figure 2a and 2b ), the sheet 100 is placed on the spray cylinder 10 . A thermal imaging camera 20 and a so-called bad page sensor 21 , which are connected to the machine control 7 , are arranged upstream of the digital printing station 3 . As a result of the rotation of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap