Carbon sliding plate preparation method

A carbon skateboard and product technology, applied in the field of rail transit, can solve the problems of carbon skateboard loss, metal bracket separation, affecting train running, etc., and achieve the effects of improving bonding performance, reducing separation, and increasing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

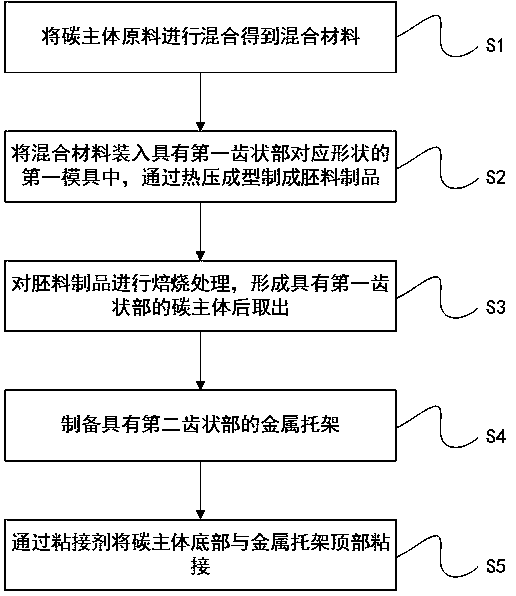

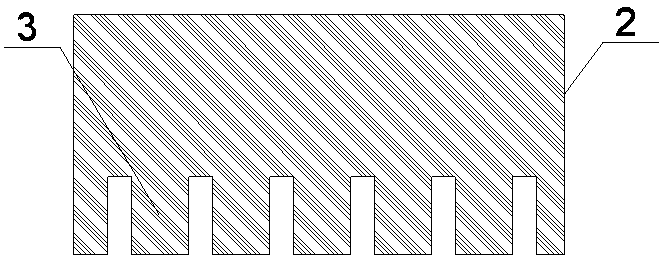

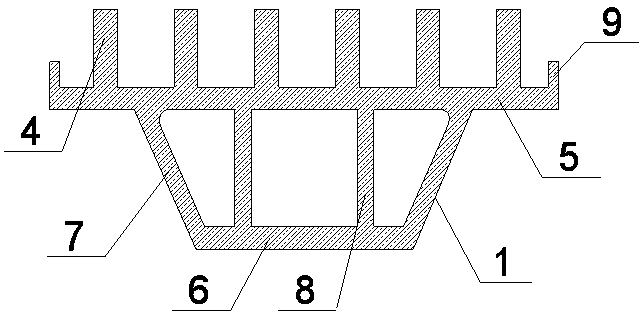

[0045] This embodiment provides a method for preparing a carbon sliding plate for a pantograph. Among them, the carbon skateboard completed with vegetation can be used on the electric traction locomotive, and used to obtain electric energy from the catenary to supply power to the electric traction locomotive, that is, to realize power extraction. The carbon slide plate is installed on the roof of the locomotive or motor vehicle. Such as Figure 4 As shown, the carbon skateboard includes: a metal bracket 1 and a carbon body 2 arranged on the metal bracket 1; wherein, the bottom of the carbon body 2 is provided with a plurality of first teeth 3, and the metal bracket The top of the frame 1 is provided with a second tooth-shaped portion 4 cooperating with the first tooth-shaped portion 3 , and the first tooth-shaped portion 3 and the second tooth-shaped portion 4 are bonded by an adhesive. Such as figure 1 As shown, the preparation method includes: S1: mixing the raw materials...

Embodiment 2

[0063] This embodiment provides a method for preparing a carbon sliding plate for a pantograph. Similar to Embodiment 1, the carbon skateboard can be used on an electric traction locomotive, and is used to obtain electric energy from the catenary to supply power to the electric traction locomotive, that is, to realize power extraction. The carbon slide plate is installed on the roof of the locomotive or motor vehicle. Such as Figure 4 As shown, the carbon skateboard includes: a metal bracket 1 and a carbon body 2 arranged on the metal bracket 1; wherein, the bottom of the carbon body 2 is provided with a plurality of first teeth 3, and the metal bracket The top of the frame 1 is provided with a second tooth-shaped portion 4 cooperating with the first tooth-shaped portion 3 , and the first tooth-shaped portion 3 and the second tooth-shaped portion 4 are bonded by an adhesive. Such as Figure 4 As shown, the preparation method includes: S1: mixing the raw materials of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com