Slewing bearing fast reversing container AGV transferring trolley

A slewing bearing and container technology, which is used in motor vehicles, transportation and packaging, etc., can solve the problems of large turning radius, tilting of the work center of gravity, and large operating space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

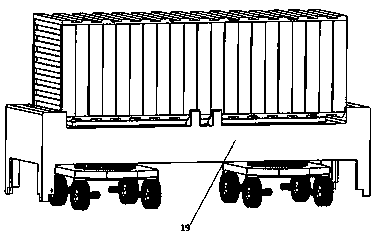

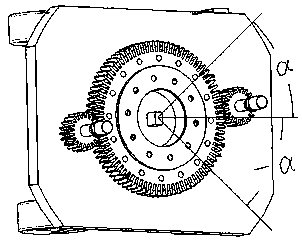

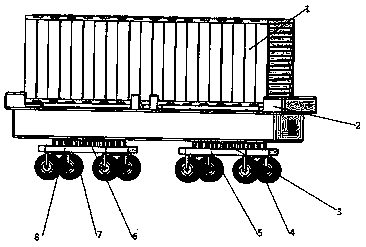

[0026] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the invention in a schematic manner, and therefore only show the configurations related to the present invention.

[0027] As shown in the picture, this picture takes a 40-foot container as an example. The present invention is a container AGV transfer vehicle with a slewing bearing and quick reversing, which can be used for the AGV transfer vehicle, so that the transfer vehicle can move forward, backward, left and right, and the turning radius of the transfer vehicle can be reduced. At the same time, it can also reduce the working center of gravity of the transfer vehicle during operation, and enhance the safety performance of the transfer vehicle.

[0028] The device adopts the rear rotary mechanism 6 and the front rotary mechanism 3 to be arranged at the bottom of the car body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com