Aircraft wing body fairing and construction method thereof

A construction method and fairing technology, applied in the field of aircraft wing body fairing and its construction, can solve the problems of small fairing size, reduced aerodynamic resistance, inconvenient and precise control of curved surface shape, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

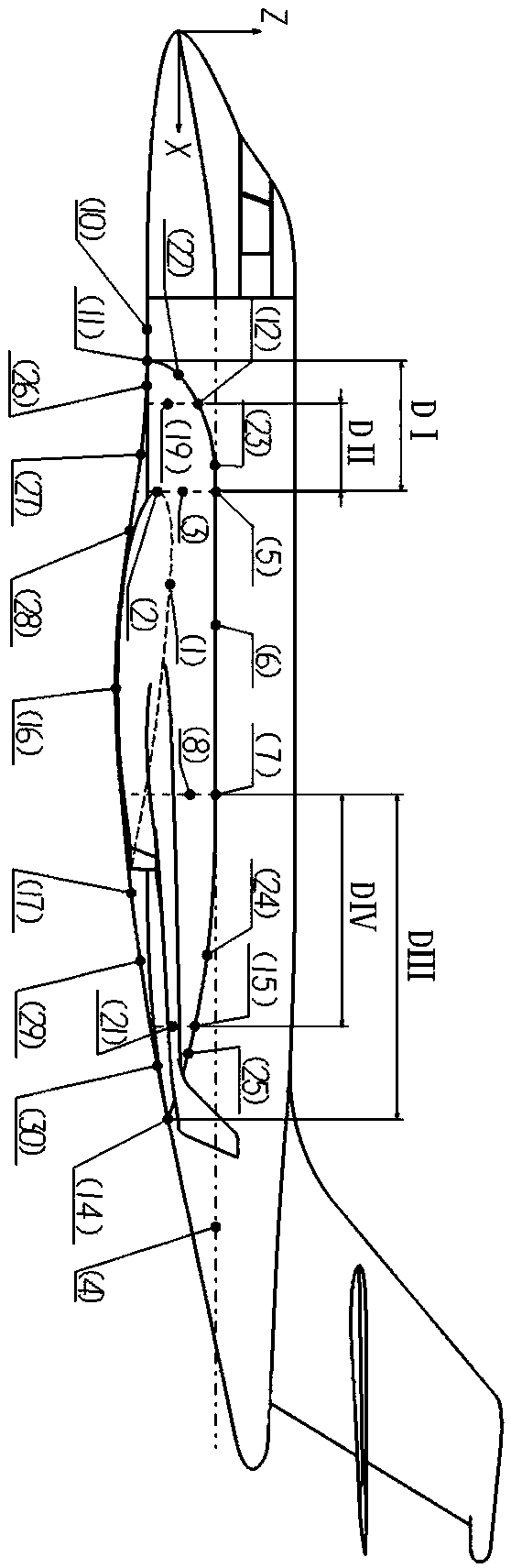

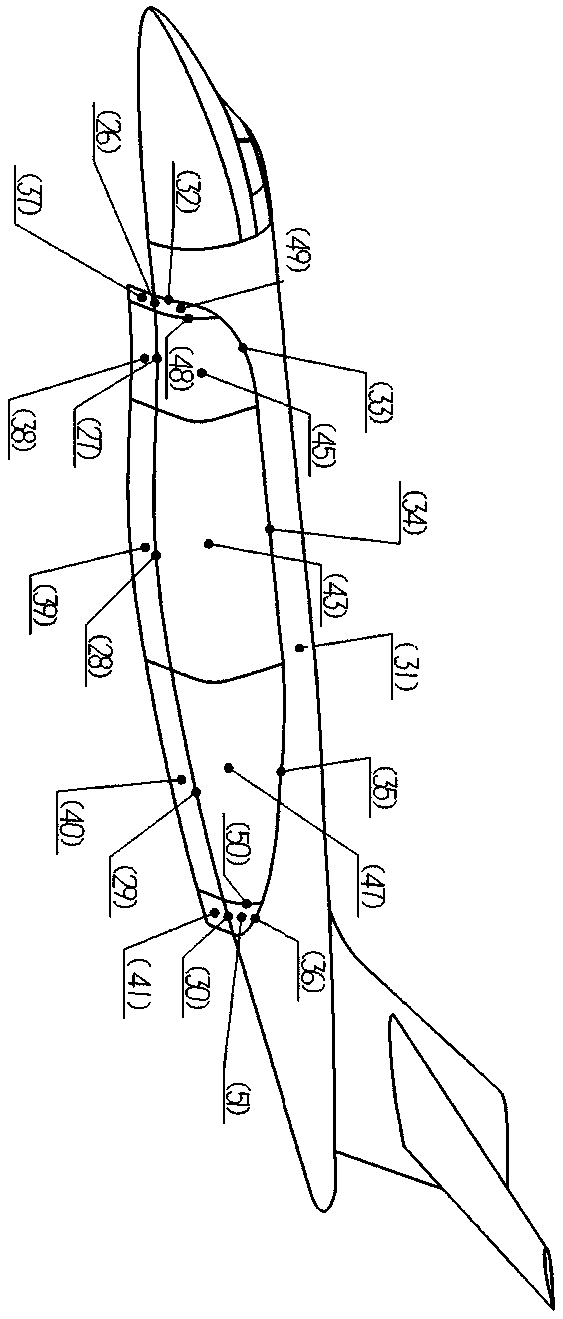

[0040] As a preferred embodiment of the present invention, with reference to the attached figure 1 to attach Figure 5 , the present embodiment discloses a kind of aircraft wing-body fairing, and the present embodiment comprises:

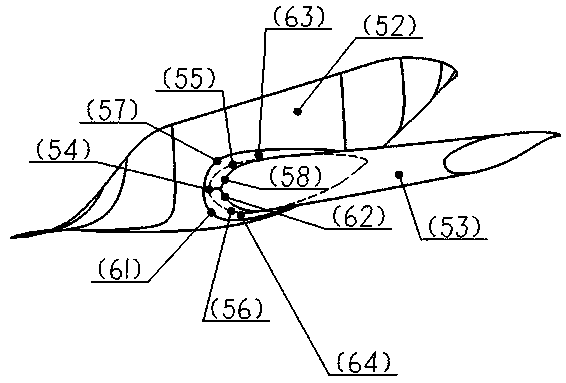

[0041] An aircraft wing-body fairing is characterized in that: it comprises a wing-body fairing main body and a fairing strip between the wing-body fairing main body and the wing, and the wing-body fairing main body successively includes a filling curved surface j49 and a conical sweeping curved surface h45 , conic sweep surface g43, conic sweep surface i47 and filled surface k51;

[0042] The fairing includes a bridging curved surface q67, a bridging curved surface r70 and a multi-section curved surface 76; there are two wing-body fairing main bodies, which are symmetrically arranged on both sides of the aircraft fuselage.

[0043] The total longitudinal length of the conic sweep surface h45 and the filling surface j49 is DI; the longitudinal len...

Embodiment 2

[0046] As a preferred embodiment of the present invention, with reference to the attached figure 1 to attach Figure 5 , present embodiment discloses a kind of construction method of aircraft wing body fairing, present embodiment comprises:

[0047] A construction method of an aircraft wing-body fairing, characterized in that it comprises the following steps:

[0048] A. Construct a coordinate system, take the vertex of the aircraft nose as the coordinate origin; the X-axis is located in the aircraft reference plane, parallel to the fuselage axis, and point to the tail; the Y-axis is perpendicular to the fuselage reference plane and points to the right, and the Z-axis is on the plane The vertical X-axis in the reference plane points upward;

[0049] B. Make the longitudinal guide line 1 of the wing-body fairing in the X-Z plane;

[0050] C. Make the longitudinal guide line 2 of the wing-body fairing in the X-Z plane;

[0051] D. Make the projection of the longitudinal guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com